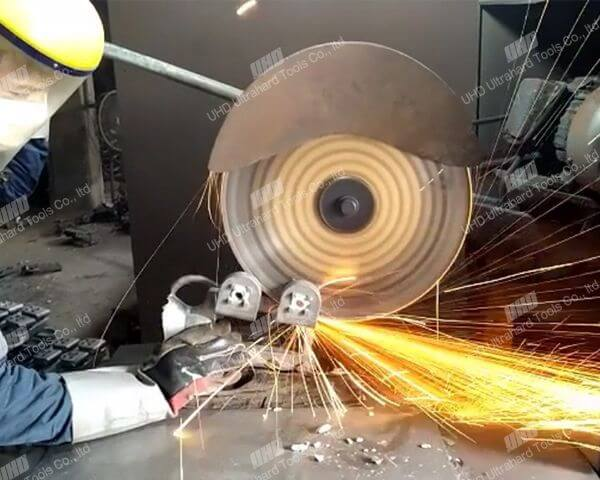

As global manufacturing continues to evolve, the choice of cutting tools plays a crucial role in determining production efficiency and cost-effectiveness. Among the many options available, the ZS400H brazed diamond saw blade from UHD Ultra Hard Materials Co., Ltd. stands out as a game-changer in industrial cutting applications. This article compares the ZS400H with traditional resin saw blades, highlighting its superior performance, durability, and environmental benefits.

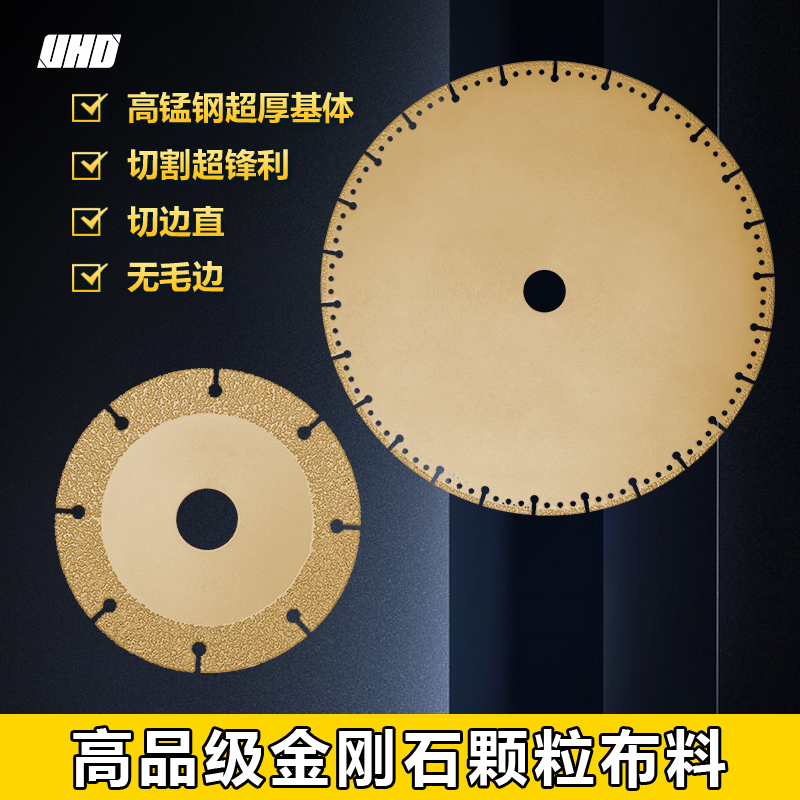

The ZS400H brazed diamond saw blade is engineered with high-grade diamond particles, offering exceptional wear resistance and sharpness. Unlike traditional resin blades that tend to dull quickly, the ZS400H maintains its cutting edge even under heavy use. According to internal testing data, the ZS400H can cut up to 30% more materials before needing replacement, significantly reducing downtime and maintenance costs.

Its high-manganese steel ultra-thick base ensures stability during operation, allowing for smooth and precise cuts. This feature is particularly beneficial when working with complex or hard-to-cut materials such as granite, concrete, and reinforced composites.

In addition to its cutting performance, the ZS400H offers significant cost savings over time. A case study conducted by a major construction company showed that switching from traditional resin blades to the ZS400H reduced material waste by 25% and lowered overall operating costs by 18%. The blade's low dust generation also contributes to a safer and cleaner work environment, aligning with modern sustainability goals.

| Feature | ZS400H Brazed Diamond Blade | Traditional Resin Blade |

|---|---|---|

| Cutting Life | Up to 30% longer | Shorter |

| Dust Generation | Low | High |

| Maintenance Cost | Lower | Higher |

Several clients have shared their positive experiences with the ZS400H. One user from a large-scale infrastructure project noted, “Since we switched to the ZS400H, our cutting speed has increased by 20%, and we’ve seen a noticeable improvement in the quality of our cuts.” Another customer highlighted the blade’s durability, stating, “We used to replace resin blades every few days, but with the ZS400H, we only need to change them once a week.”

The ZS400H brazed diamond saw blade is not just an upgrade—it’s a strategic investment. With its enhanced cutting efficiency, reduced operational costs, and eco-friendly design, it provides a competitive edge in today’s demanding industrial landscape. Whether you’re involved in construction, mining, or precision manufacturing, the ZS400H delivers consistent performance and long-term value.

Ready to transform your cutting operations? Discover the power of the ZS400H and take your productivity to the next level. Contact us today to learn more about how the ZS400H can benefit your business.