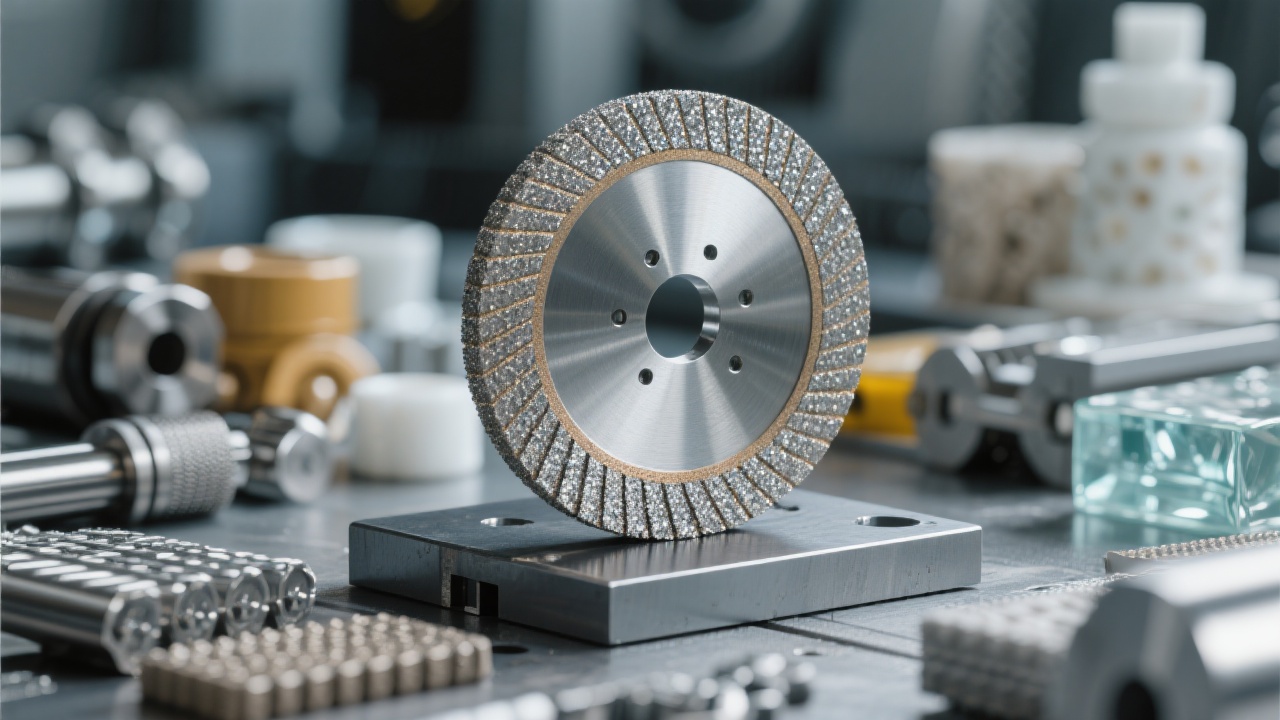

In the competitive world of stone processing, finding the right cutting tool can make all the difference. The 400H diamond saw blade has become a go - to choice for professional stone processing personnel. But what makes it so popular? Let's delve into real - world customer cases to find out.

The 400H saw blade has earned a stellar reputation in the stone processing and construction industries. It's often recommended by experienced craftsmen and is a staple in many professional toolkits. This widespread recognition is not without reason, as it offers a range of features that address the common pain points faced by users.

The 400H saw blade utilizes advanced brazing technology. This process ensures a strong bond between the diamond segments and the blade body. In contrast to traditional methods, brazed joints can withstand higher stress and heat, which is crucial during high - speed cutting operations. For example, in a continuous cutting test, the brazed joints of the 400H saw blade showed no signs of loosening after 100 hours of operation, while non - brazed saw blades often start to experience segment loss after just 30 hours.

Durability is a key factor in any cutting tool, and the 400H saw blade excels in this regard. Its super - wear - resistant blade head design can significantly extend the service life of the saw blade. Tests have shown that the 400H saw blade can cut through approximately 30% more material than ordinary saw blades before needing replacement. This means fewer blade changes, less downtime, and ultimately, cost savings for the user.

One of the most annoying problems in cutting operations is excessive vibration, which can lead to poor cutting quality, increased operator fatigue, and even damage to the equipment. The 400H saw blade features a low - vibration design. In a practical test, the vibration level of the 400H saw blade was measured to be 20% lower than that of a standard saw blade. This reduction in vibration not only improves the cutting accuracy but also makes the operation more comfortable for the user.

Whether it's a shallow cut for fine detailing or a deep cut for heavy - duty work, the 400H saw blade can handle it all. Its design allows for flexible adjustment of the cutting depth, making it suitable for a wide range of applications.

Case 1: Construction Site

On a large - scale construction site in the United States, the construction team was facing challenges with high - noise and rapid wear of their existing saw blades when cutting concrete. After switching to the 400H saw blade, the situation improved significantly. "The 400H saw blade has been a game - changer for us. The noise level has dropped by about 30%, and we've noticed a big reduction in blade wear. We can now work longer hours without having to constantly replace the blades," said the site foreman, John.

Case 2: Stone Factory

A stone factory in Italy was struggling with compatibility issues when processing different types of marble. Their old saw blades were unable to provide a consistent cut quality across various marble grades. The 400H saw blade solved this problem. "This saw blade can adapt to different marble hardness levels. It gives us a clean and precise cut every time. Our production efficiency has increased by about 25% since we started using it," said the factory manager, Marco.

| Features | 400H Saw Blade | Ordinary Saw Blade |

|---|---|---|

| Service Life | Can cut 30% more material | Shorter service life |

| Noise Level | 30% lower | Higher noise |

| Vibration | 20% lower | Higher vibration |

| Compatibility | Good for various materials | Limited compatibility |

The 400H saw blade offers a combination of time - saving, labor - saving, and cost - effective features. By reducing the frequency of blade replacement, lowering noise and vibration levels, and improving cutting quality, it helps professional users enhance their productivity and gain a competitive edge in the market.

If you're in the stone processing or construction industry, have you faced similar problems as the customers in these cases? What kind of cutting challenges are you currently dealing with? Share your experiences in the comments below, and let's discuss how the 400H saw blade can be your solution. Discover more about the 400H saw blade now!