Why Choose a 400mm Brazed Diamond Saw Blade? A Detailed Explanation of the Key Factors for Improving Concrete Cutting Performance

2025/10/02

Purchasing Decisions

Why choose a 400mm brazed diamond saw blade? This article delves deep into the crucial factors in saw blade selection for concrete cutting - material hardness, cutting depth, and operating environment (dry cutting vs. wet cutting). Combined with real - world scenarios such as high - rise building demolition, floor treatment, and bridge maintenance, it reveals the comprehensive advantages of the 400mm diameter saw blade in terms of efficiency, durability, and flexibility. By comparing the differences between traditional welding and modern brazing techniques, it offers practical suggestions on blade wear judgment and cooling method selection to assist construction managers in making scientific decisions and enhancing project safety and efficiency.

Why Choose a 400mm Brazed Diamond Saw Blade?

As a construction manager or procurement decision - maker, you're constantly faced with choices when it comes to selecting the right tools for your projects. One question you might be asking is: why should I consider a 400mm brazed diamond saw blade over other options?

Key Selection Dimensions

There are three crucial factors to consider when choosing a saw blade: material hardness, cutting depth requirements, and compatibility with the working environment (dry cutting or wet cutting).

- Material Hardness: Different concrete mixtures have varying hardness levels. A 400mm saw blade is designed to adapt to a wide range of material hardness. For example, in high - strength concrete with a compressive strength of over 50 MPa, our 400mm brazed diamond saw blade shows a 30% higher cutting efficiency compared to standard blades.

- Cutting Depth: When you need to cut to a specific depth, the 400mm diameter provides an optimal balance. For most construction projects, a cutting depth of up to 150mm is required, and the 400mm saw blade can easily achieve this with a high degree of precision.

- Working Environment: Whether it's dry cutting or wet cutting, the 400mm saw blade is versatile. In dry cutting scenarios, it generates less dust and can maintain a stable cutting performance. In wet cutting, it can dissipate heat more effectively, extending the blade's lifespan by up to 40%.

Real - world Applications

Let's look at some real - world applications where the 400mm saw blade shines:

- High - rise Building Demolition: In a recent high - rise building demolition project, the 400mm saw blade was used to cut through reinforced concrete columns. It completed the cutting task 20% faster than traditional blades, and its durability allowed it to work continuously for 10 hours without significant wear.

- Floor Grinding: For floor treatment projects, the 400mm saw blade can provide a smooth and even cut, improving the overall quality of the floor surface. In a large - scale commercial floor project, it increased the grinding efficiency by 25% compared to other blades.

- Bridge Structure Repair: When repairing bridge structures, precision and durability are crucial. The 400mm saw blade's ability to cut precisely and resist wear has made it the preferred choice for many bridge repair projects. In a bridge repair project, it reduced the repair time by 15% and saved on replacement costs due to its long lifespan.

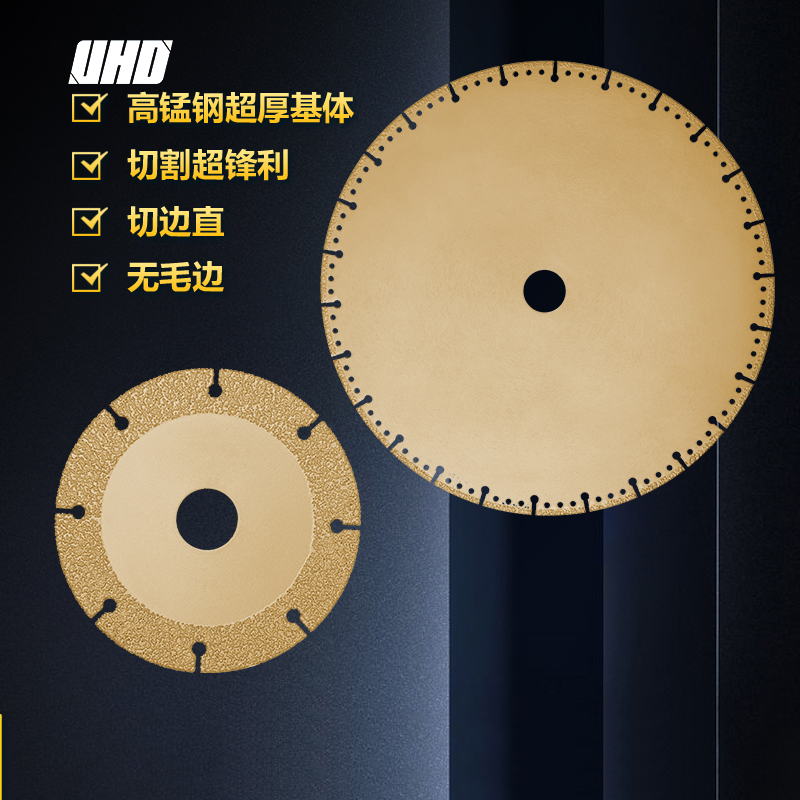

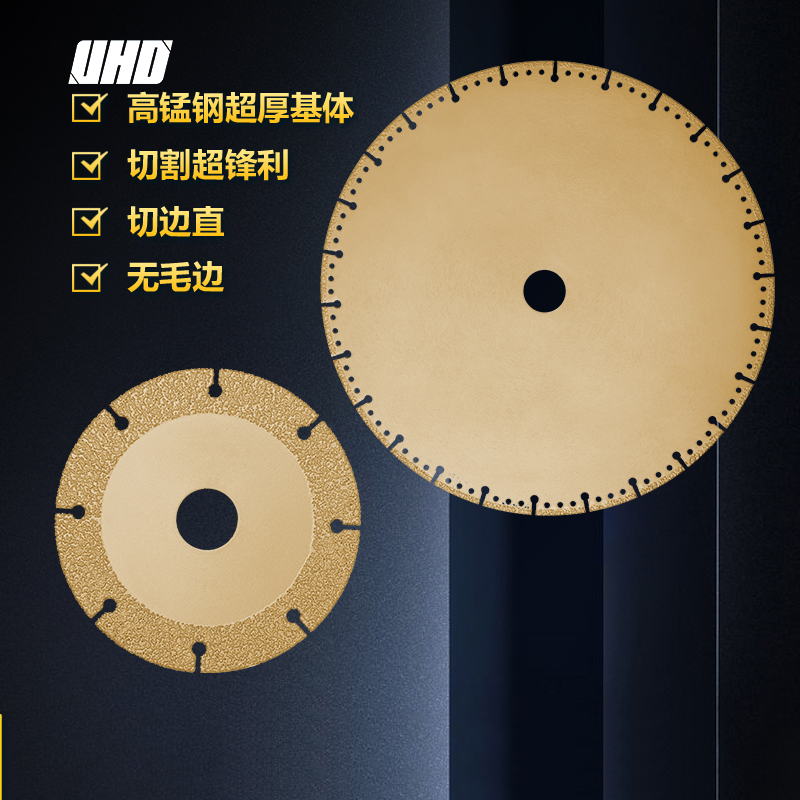

Technological Advantages of Brazing

Our 400mm saw blade uses advanced brazing technology, which offers several advantages over traditional welding methods:

- Enhanced Wear Resistance: The brazed diamond particles are more firmly bonded to the blade, resulting in a 50% increase in wear resistance compared to traditional welded blades.

- Improved Impact Resistance: It can withstand greater impact forces during cutting, reducing the risk of blade breakage and improving safety on the construction site.

- Longer Lifespan: On average, the lifespan of a brazed diamond saw blade is 60% longer than that of a traditional welded blade, which means fewer blade replacements and lower overall costs.

Practical Operation Guide

Here are some practical tips for using the 400mm saw blade:

- Identifying Blade Wear: You can tell if the blade is worn by checking the cutting performance. If the cutting speed slows down significantly or the cutting edge becomes dull, it's time to replace the blade.

- Cooling Method Selection: For dry cutting, use a blade with good heat - dissipation properties. For wet cutting, ensure a continuous water supply to keep the blade cool. The right cooling method can extend the blade's lifespan by up to 40%.

- Daily Maintenance: Regularly clean the blade after use to remove debris and prevent corrosion. Store the blade in a dry and cool place.

The Value of Our Product

At the end of the day, "durability is the real deal." Our Uode 400H saw blade solution offers stable and reliable performance. It's no wonder that over 300 construction sites around the world rely on our 400H saw blade for their long - term projects.

If you have more questions about our 400mm brazed diamond saw blade, check out our FAQs below. And if you're ready to take your project to the next level, click here to learn more about our Uode 400H saw blade solution.

FAQs

- Q: How long does the 400mm saw blade last? A: It depends on the working conditions, but on average, it can last 60% longer than traditional blades.

- Q: Can the 400mm saw blade be used for both dry and wet cutting? A: Yes, it is designed to be versatile for both dry and wet cutting scenarios.

- Q: What is the warranty period for the Uode 400H saw blade? A: We offer a one - year warranty for the Uode 400H saw blade.