What Saw Blades Are Best for High-Rise Building Demolition? Advantages of 400mm Brazed Diamond Blades in Structural Cutting

2025/09/05

Tutorial Guide

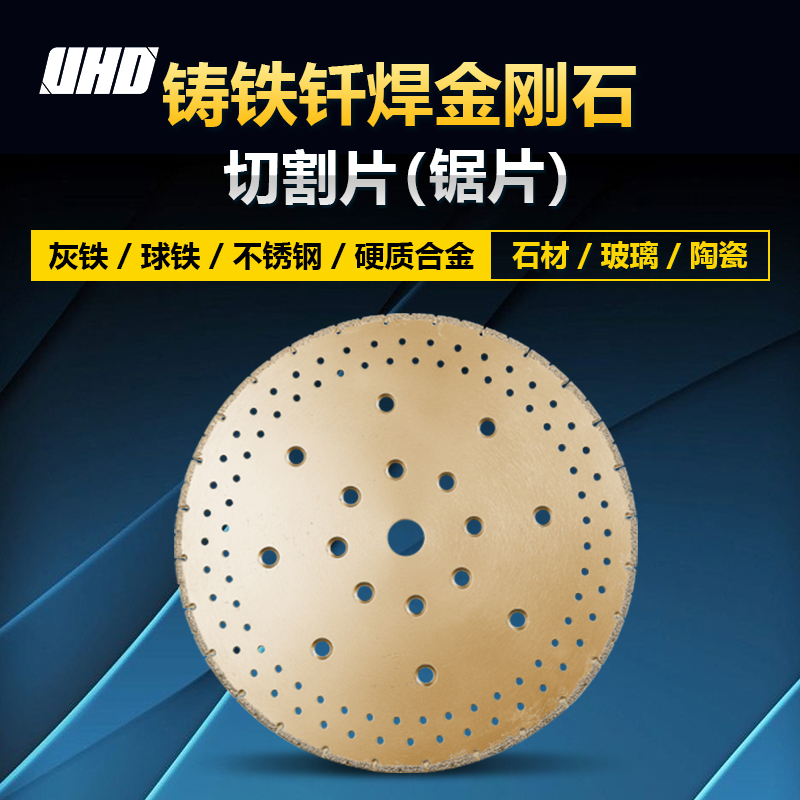

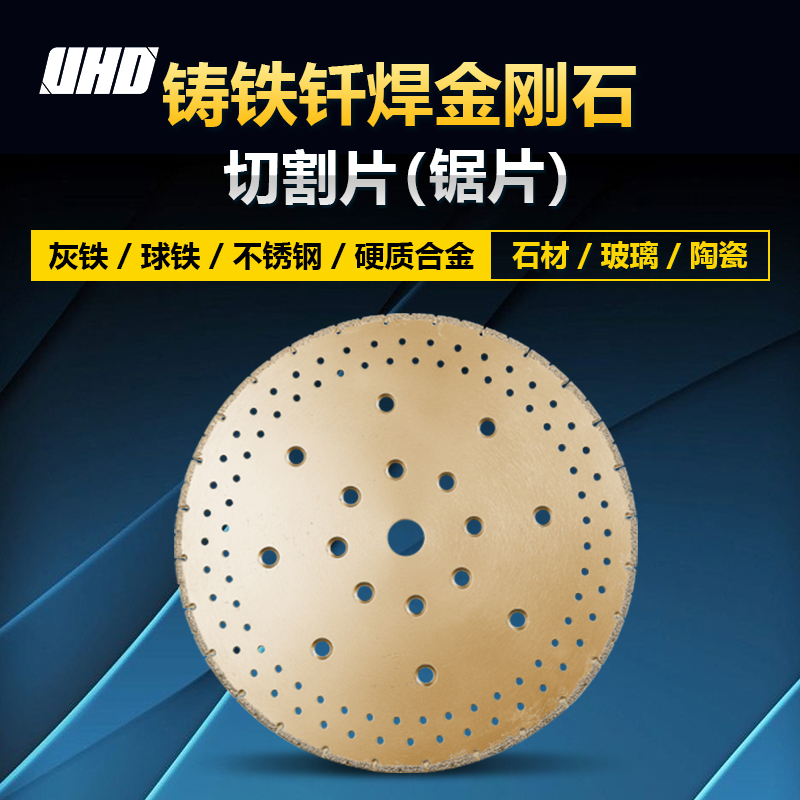

Which saw blade is ideal for high-rise building demolition? The 400mm brazed diamond blade stands out as the preferred choice, offering exceptional wear resistance, versatile cutting depths, and compatibility with both dry and wet cutting environments. This article explores its advantages in cutting high-hardness materials such as concrete and granite, compares brazed fusion technology with traditional welding methods, and presents practical insights from real-world applications including high-rise renovation, floor processing, and bridge maintenance. It also provides hands-on guidance on blade wear identification and cooling method selection to support informed blade selection and efficient operation.

Choosing the Right Saw Blade for High-Rise Building Demolition

In the demolition sector, selecting the appropriate saw blade significantly impacts operational efficiency and safety. When tackling high-rise structures composed of tough materials such as concrete and granite, the 400mm brazed diamond saw blade has emerged as a leading solution, combining durability, cutting flexibility, and versatility for dry and wet environments.

Key Factors in Saw Blade Selection

The performance of saw blades depends on three core dimensions:

- Material Hardness: Substrate material like concrete or granite demands blades with exceptional abrasion resistance.

- Cutting Depth: Adequate blade diameter determines maximum cut depth—400mm suits a wide range of structural tasks.

- Operating Environment: Compatibility with both dry and wet cutting impacts blade cooling and dust control.

Why a 400mm Brazed Diamond Saw Blade Excels in High-Rise Demolition

The 400mm brazed diamond blade perfectly balances aggressive cutting performance with long service life. Its brazed segments ensure the diamond grit bonds strongly to the steel core, minimizing premature segment loss — a common drawback in traditional welding methods.

| Feature |

Brazed Diamond Blade |

Traditional Welded Blade |

| Segment Bond Strength |

High – reduced segment loss |

Moderate – prone to segment detachment |

| Durability |

Superior resistance to wear |

Lower wear resistance |

| Cutting Stability |

Consistent throughout blade life |

Potential vibration as segments wear |

Engineers on site report that brazed blades often extend operational lifetimes by 30-50% compared to welded alternatives, enhancing project schedules and lowering blade replacement frequency.

Tailored Performance in Key Demolition Scenarios

The 400mm brazed diamond blade demonstrates versatility across typical demolition tasks such as:

- Concrete floor and pavement cutting: Clean, deep cuts reduce cracking risk and improve surface preparation.

- Bridge structural repair: Precision cutting without compromising material integrity.

- High-rise structure façade and core demolition: Faster penetration and reduced downtime.

Operational Tips for Optimal Blade Performance

To maximize lifespan and efficiency, operators should be aware of these actionable strategies:

- Blade Wear Assessment: Monitor segment wear visually and via cutting quality indicators. When segment height reduces below 3mm, replacement or dressing is recommended.

- Cooling Technique Selection: Utilize wet cutting for extended blade life and dust suppression. Dry cutting suits quick tasks with enhanced portability but may increase segment wear.

- Rotation Speed Compliance: Adhere strictly to the blade’s maximum RPM rating (typically 6,600 RPM for 400mm) to avoid structural damage.

“The brazed diamond blade’s durability and adaptability have transformed our demolition workflow, reducing downtime and cutting costs on multiple landmark developments.” – Senior Project Manager, Global Construction Firm

These blades have been validated in numerous large-scale projects, meeting the demands of engineering teams who prioritize durability, cutting accuracy, and long-term cost efficiencies.

Explore How 400mm Brazed Diamond Saw Blades Can Elevate Your Demolition Projects