In today's fiercely competitive industrial manufacturing landscape, the choice of cutting tools directly influences productivity, operational costs, and environmental compliance. Global manufacturers continuously seek cutting-edge solutions that combine power, precision, and longevity. The ZS400H Brazed Diamond Saw Blade, developed by UHD Superhard Materials Tools Co., Ltd., emerges as a transformative breakthrough — designed to meet the demanding needs of modern industrial cutting applications.

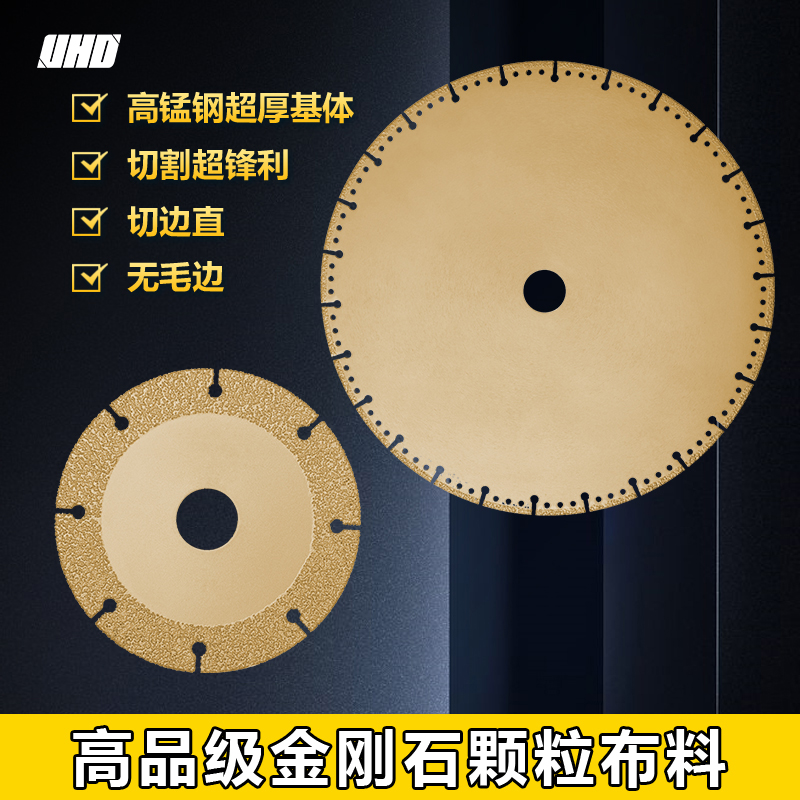

Crafted with precision, the ZS400H employs premium-grade synthetic diamond particles embedded via advanced brazing technology — resulting in a cutting edge that surpasses traditional resin-bound blades in sharpness and wear resistance. This blade’s robust high-manganese steel super-thick base plate not only guarantees exceptional structural stability during high-speed operations but also enhances user safety by minimizing vibration and deformation.

| Specification | ZS400H Blade | Traditional Resin Blade |

|---|---|---|

| Diamond Grain Quality | High-grade synthetic diamond particles | Standard resin-embedded grains |

| Base Material | High-manganese steel, 3.5mm thickness | Steel, 1.5-2mm thickness |

| Wear Resistance | Up to 50% longer lifespan | Standard service life |

| Cutting Efficiency | Smooth, low friction, high precision | Frequent blade change, less precision |

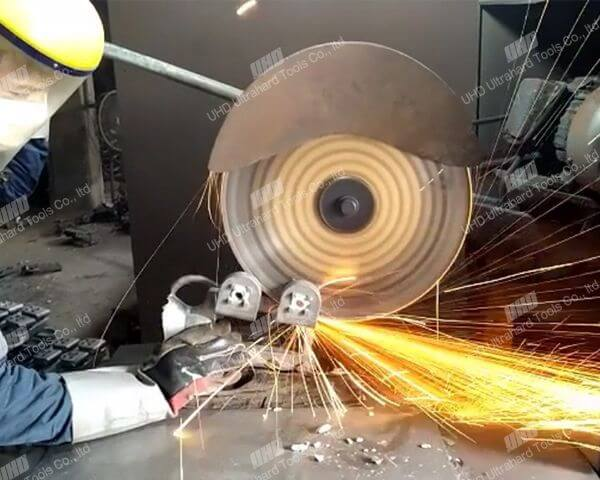

The ZS400H blade excels in cutting complex and high-hardness materials including reinforced concrete, ceramics, and composite metals, commonly encountered in aerospace, automotive manufacturing, and precision construction parts. Thanks to its brazed diamond composition, users report a 35% reduction in cutting cycle time compared to conventional resin blades. This improvement directly translates to substantial labor cost savings and increased throughput.

Moreover, its design dramatically reduces airborne dust generation by approximately 40%, aligning with global environmental and workplace safety regulations. This low dust feature not only protects worker health but also reduces dust-related equipment maintenance and cleaning expenses.

One multinational automotive parts supplier integrated the ZS400H blade into their high-precision machining lines. Within three months, their data revealed:

These measurable benefits underscore how the ZS400H not only boosts operational efficiency but also contributes to cleaner, safer manufacturing environments — a decisive edge for enterprises aiming for sustainable growth.

Durability: Engineered from premium diamonds and reinforced steel, the blade delivers a lifespan up to 50% longer than traditional alternatives.

Precision & Performance: Ensures smooth, accurate cuts for complex industrial components, minimizing rework.

Eco-Friendly & Safe: Reduced dust emissions and stable blade behavior create a healthier worksite.

Cost Efficiency: Saves labor, maintenance, and replacement costs, enhancing ROI.

Trusted Quality: Backed by rigorous testing and real-world validation across multiple industries.

The ZS400H Brazed Diamond Saw Blade is your ideal partner to elevate industrial cutting—unlocking unmatched efficiency, safety, and durability for your manufacturing operations.