In global industrial manufacturing, cutting tools are integral to ensuring the precision, speed, and efficiency of production processes. Especially in sectors such as automotive, aerospace, and heavy machinery, where accuracy and material integrity dictate product quality, the choice of cutting tools directly influences operational success. UHD Superhard Materials Tools Co., Ltd. stands at the forefront of this arena, offering state-of-the-art diamond cutting tools engineered with ultra-hard materials to meet and exceed the exacting demands of modern industry.

UHD Superhard Materials Tools Co., Ltd. distinguishes itself by leveraging strategic partnerships with renowned universities and research institutions worldwide. This collaboration accelerates innovation cycles, allowing for the continuous refinement of cutting-edge materials science and precision engineering. Through joint research projects and rigorous testing protocols, UHD’s products consistently comply with international standards such as ISO 9001 and ISO 14001, ensuring reliability, environmental responsibility, and superior quality.

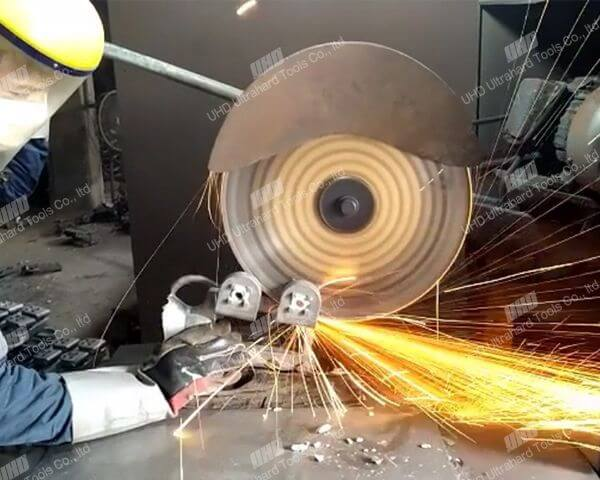

UHD’s diamond cutting tools are meticulously engineered for ultra-precise metalworking applications. Employing advanced design software and precision manufacturing techniques, each tool optimizes blade geometry and bonding compounds to enhance cutting accuracy and durability. These tools achieve exceptionally low tolerances—often within micrometer ranges—making them ideal for high-precision industries such as semiconductor fabrication and aerospace component manufacturing.

Furthermore, UHD’s products exhibit outstanding wear resistance and thermal stability, drastically reducing tool degradation under demanding working conditions. This enhanced durability translates to fewer tool replacements and minimized production downtime, substantially lowering maintenance costs.

UHD offers an extensive range of diamond cutting tools encompassing discs, blades, and segments suitable for various materials including hardened steel, titanium alloys, and complex composites. Recognizing the heterogeneous requirements across industries, UHD provides tailored product customization tailored to specific operational parameters, such as cutting speed, thickness, and application environment.

This flexibility empowers manufacturers to deploy tools optimized for their unique workflows, maximizing efficiency while preserving quality integrity.

| Client Industry | Production Challenge | Outcome after UHD Tool Integration |

|---|---|---|

| Aerospace Components | High frequency of tool wear causing frequent stoppages | 80% reduction in tool replacements; 15% increase in line uptime |

| Automotive Manufacturing | Need for precise cutting of hard alloys without compromising finish | Achieved cutting precision to ±5 microns; improved product yield by 10% |

| Heavy Machinery Fabrication | Frequent production halts due to maintenance of substandard tools | Reduced unscheduled downtime by 25%; cut maintenance costs by 18% |

UHD’s commitment to excellence is demonstrated through its pioneering research collaborations, precise engineering, and dedication to meeting bespoke client requirements. Selecting UHD cutting tools means integrating high-efficiency, reliable, and premium-quality solutions into your production line — translating into enhanced throughput, sustained precision, and measurable cost savings.

Partner with UHD Superhard Materials Tools Co., Ltd. today to access cutting-edge diamond cutting tools that deliver precision and performance the world’s leading industrial manufacturers trust.

Contact UHD Sales Team Now