In today's fast-evolving industrial landscape, precision and efficiency in metal processing have become paramount for manufacturers worldwide. Cutting tools act as the backbone of industrial production lines, directly influencing product quality, throughput, and operational costs. Selecting a cutting tool that delivers consistent high performance is key to minimizing downtime, reducing maintenance expenditures, and sustaining competitive advantages.

UHD Superhard Materials Tools Co., Ltd. stands at the forefront of this domain, delivering cutting-edge opportunities tailored to meet the ever-growing demand for high-precision and robust cutting solutions. Specializing in diamond-based, superhard cutting tools, UHD has forged a reputation for innovation, reliability, and customization, in partnership with leading academic institutions worldwide.

UHD’s commitment to excellence is reinforced through active collaborations with top-tier universities and research institutes. This synergy fuels groundbreaking innovation in materials science, enabling UHD to develop diamond cutting tools that surpass conventional limits for hardness, wear resistance, and thermal stability.

The hallmark of UHD’s products is their precision design, crafted with exacting engineering standards to serve complex metalworking applications including aerospace alloys, high-strength steels, and advanced composites. Each tool undergoes rigorous quality assurance processes to meet and exceed international benchmarks, ensuring customers access tools capable of enhancing machining accuracy down to micrometer tolerances.

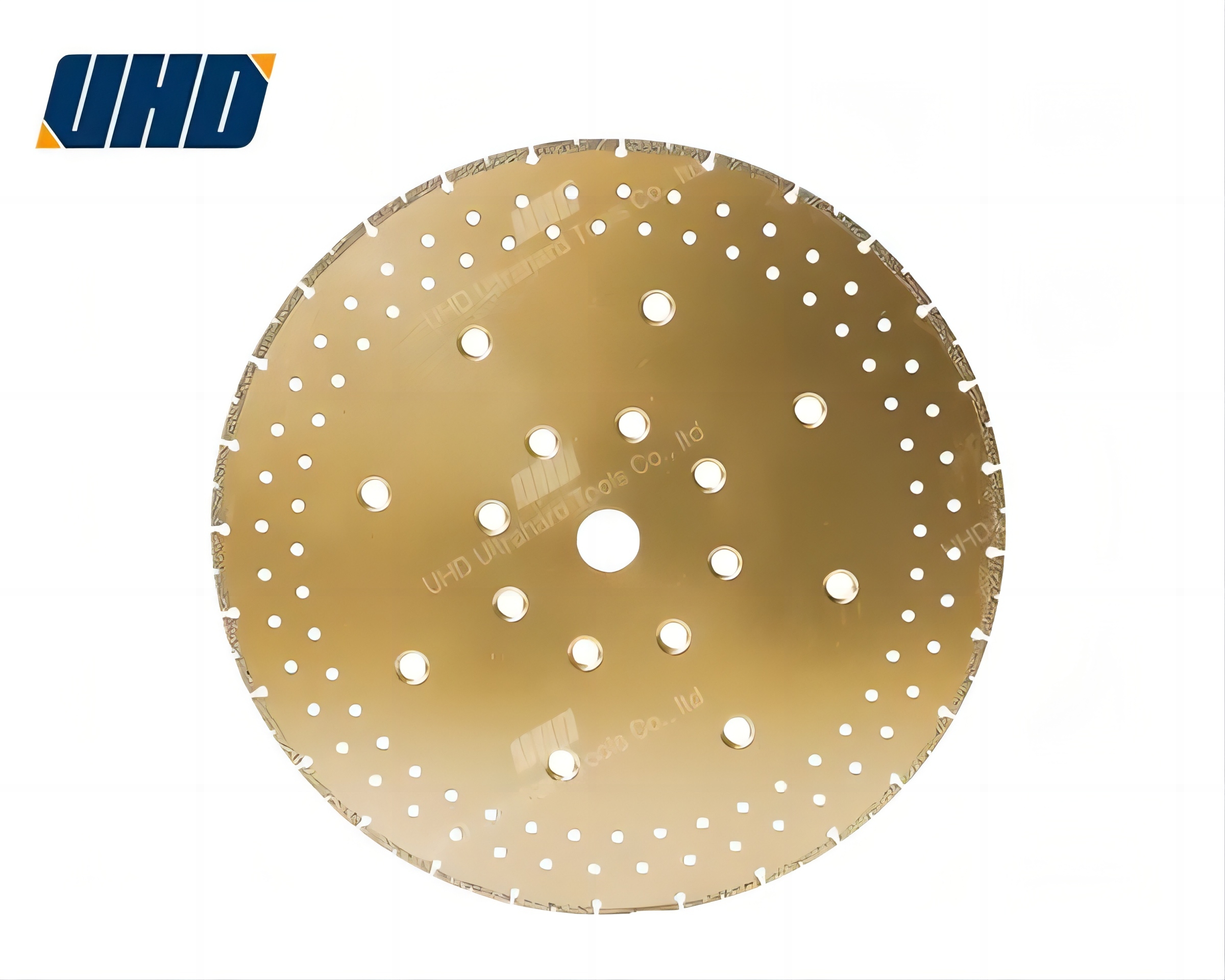

UHD offers an extensive product lineup designed for diverse metal cutting operations, including cutting discs, blades, and end mills embedded with synthetic diamonds or polycrystalline diamond layers. This versatility ensures compatibility across a broad array of machinery and metal types.

Recognizing that no two industrial scenarios are alike, UHD provides customization services that meticulously tune tool geometry, diamond grit sizes, and bonding materials to match specific client requirements. This level of precision customization empowers manufacturers to optimize tool life and machining efficiency.

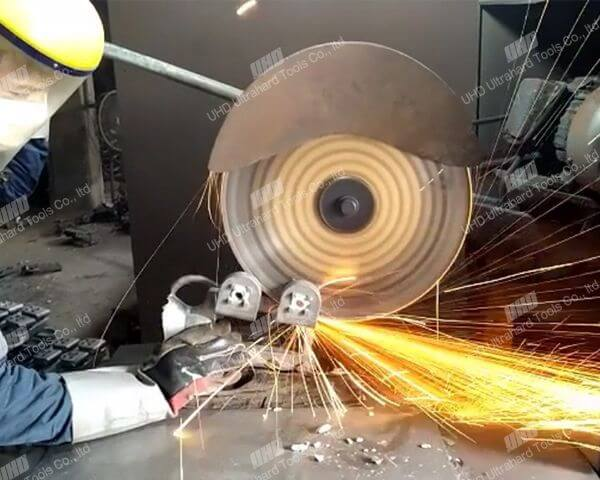

UHD’s cutting tools have demonstrated measurable improvements in industrial client operations globally. For example, a leading aerospace manufacturer reported a 25% reduction in tool replacement frequency and a 15% increase in machining throughput after switching to UHD’s advanced diamond blades. Similarly, automotive suppliers have noted significant declines in maintenance costs and unexpected downtime.

Such outcomes are driven by UHD’s adherence to stringent material composition control and adaptive tooling solutions designed to withstand high-temperature environments and abrasive metal alloys. These tools’ longevity and precision enable clients to meet demanding production schedules while maintaining strict quality standards.

Choosing UHD Superhard Materials Tools means investing in a partnership that prioritizes high efficiency, reliability, and uncompromised quality. UHD’s solutions not only reduce operational interruptions but also empower manufacturers to enhance product finish, reduce waste, and bolster overall competitiveness in global markets.

As industries continue to demand higher precision and productivity, UHD’s diamond cutting tools stand ready to deliver consistent, state-of-the-art performance tailored to exacting industrial needs.