In today's highly competitive manufacturing environment, precision, durability, and efficiency of cutting tools are paramount. Industrial enterprises demand tool solutions that not only maintain stringent accuracy but also reduce downtime and maintenance expenses. UHD Superhard Materials Tools has positioned itself as a global leader by delivering diamond cutting tools that meet the rigorous demands of high-precision metal processing, thereby becoming the benchmark for industrial cutting tools worldwide.

UHD’s commitment to innovation is solidified through strategic partnerships with leading academic institutions. These collaborations advance research in materials science and precision engineering, enabling UHD to pioneer technology that elevates the performance of diamond cutting tools. By integrating academic insights with industrial expertise, UHD tools consistently surpass international quality standards, achieving precision tolerances as tight as ±2 microns in metal cutting applications.

At the heart of UHD’s cutting tools lies a multi-faceted design approach, incorporating:

This meticulous engineering results in tools capable of maintaining edge sharpness up to 30% longer than conventional counterparts, significantly reducing tool changes and machine idle time on modern CNC equipment.

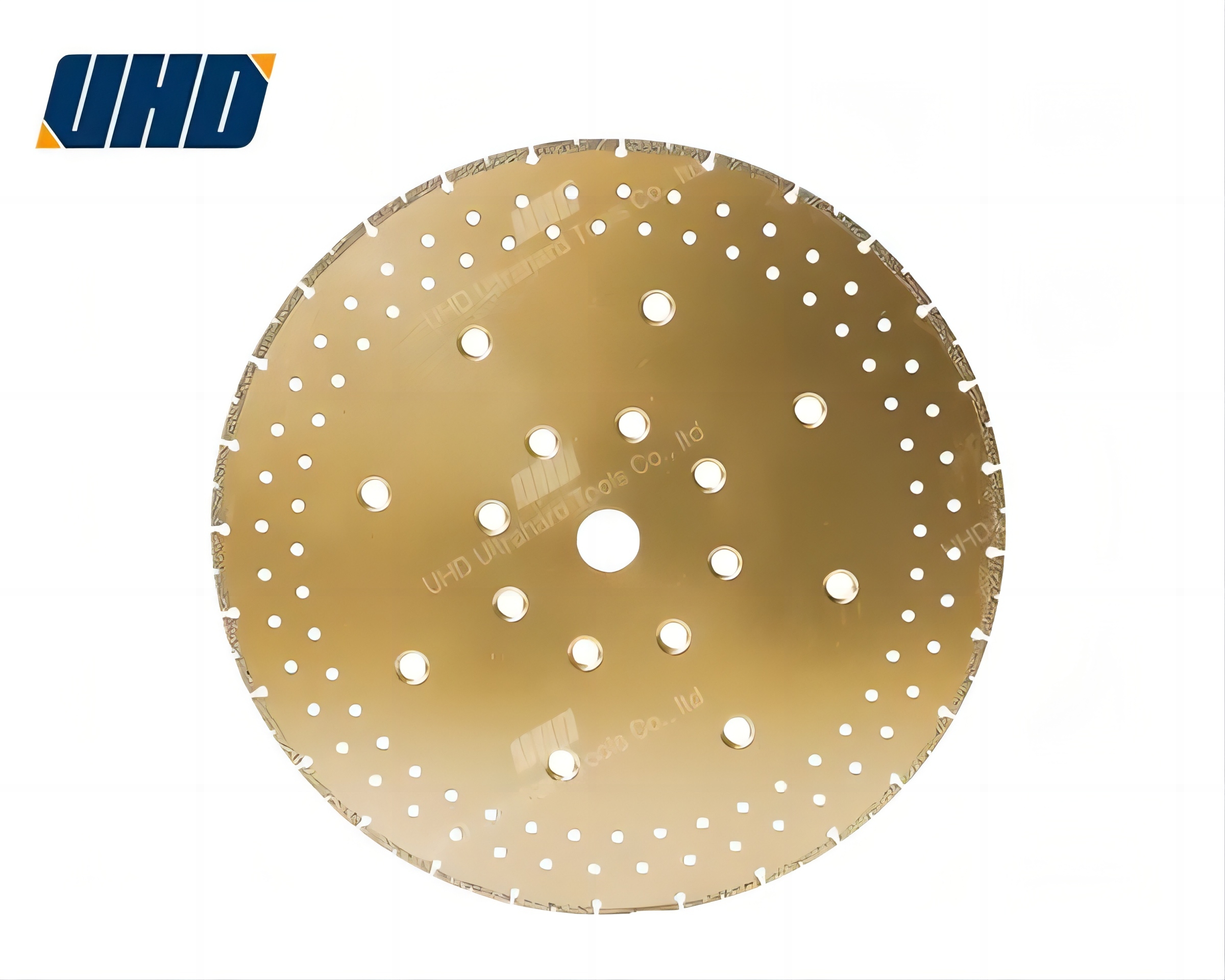

UHD offers a diverse portfolio including circular saw blades, grinding wheels, and customized cutting solutions for varied industrial applications:

| Product Type | Application | Customization Options |

|---|---|---|

| Diamond Saw Blades | High-precision cutting of hardened metals and composites | Diameter, diamond grit, bonding matrix tailored to job requirements |

| Grinding Wheels | Surface finishing and ultra-fine metal shaping | Wheel size, hardness, and diamond concentration customizable |

| Specialized Cutting Tools | Complex geometries and niche industrial applications | Full design consultation and bespoke manufacturing |

Numerous global clients have reported transformational improvements after switching to UHD diamond cutting tools. For example, a European aerospace manufacturer reduced tool changeover frequency by 25%, leading to a 15% boost in overall equipment effectiveness (OEE). Simultaneously, maintenance costs dropped by 18% annually due to extended tool longevity and minimized machine downtime.

Another case study from a large-scale automotive parts producer demonstrated that UHD's product customization enabled processing of advanced alloys with tolerances under ±5 microns, improving product quality consistency while lowering scrap rates by 12%.

Selecting UHD cutting solutions translates directly to operational efficiencies:

UHD’s tools empower manufacturers worldwide to meet demanding production schedules while controlling operational budgets — a winning formula for sustained industrial competitiveness.