In today's competitive industrial landscape, the precision and durability of cutting tools are indispensable to achieving manufacturing excellence. Cutting tools play a pivotal role in metalworking and fabrication processes, directly impacting production efficiency, product quality, and operational costs. As industries demand increasingly high precision and consistent performance, the selection of cutting tools becomes a critical decision for global procurement professionals targeting enhanced productivity and long-term cost savings.

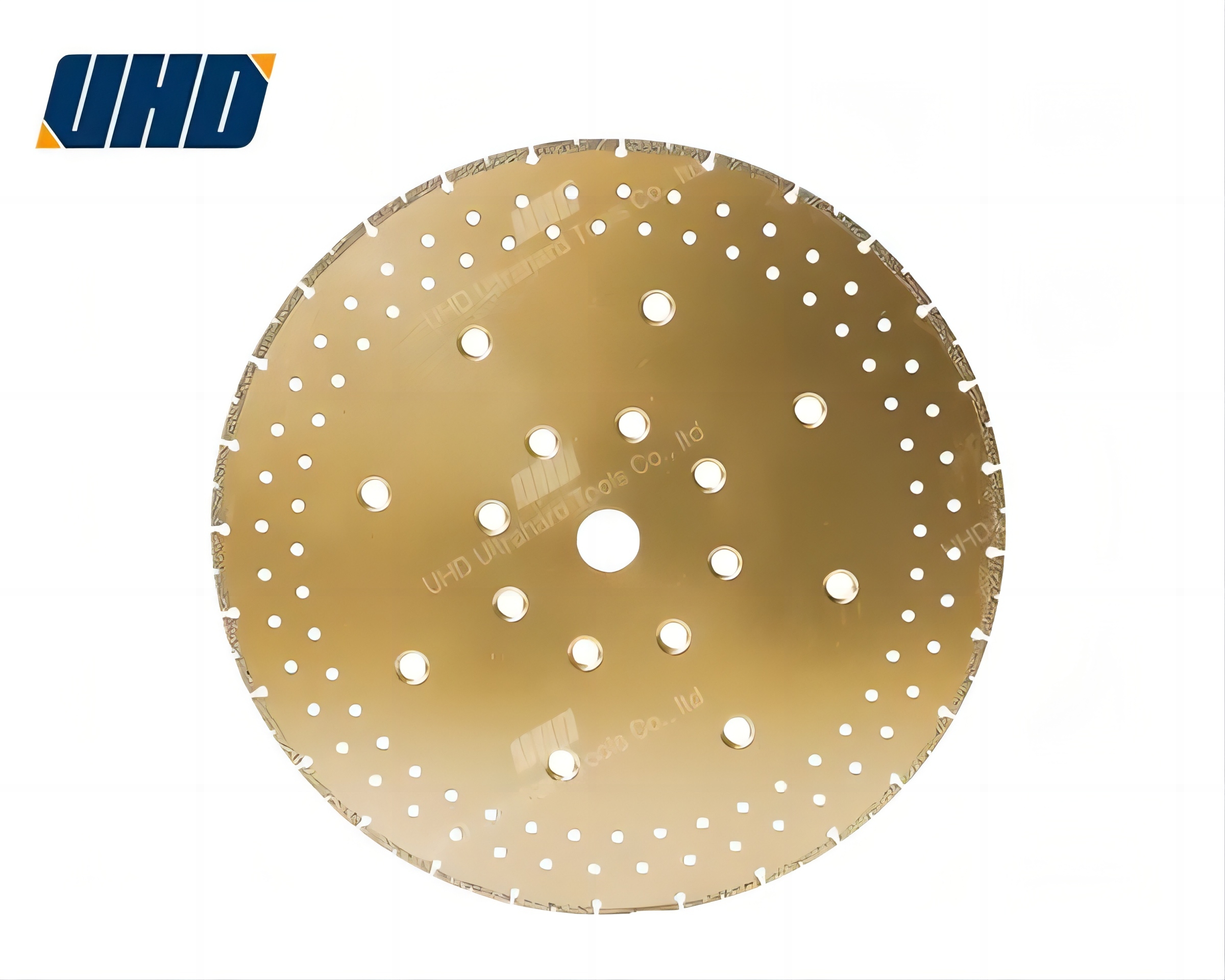

UHD Superhard Materials Tools Co., Ltd. stands out as a leader in manufacturing diamond cutting tools engineered for ultra-precision metalworking applications. Their collaborative partnerships with prominent universities facilitate advanced research and development, enabling UHD to adhere to international quality standards consistently. This synergy of academic expertise and industrial know-how ensures cutting tools designed with meticulous attention to geometry, material composition, and wear resistance.

What sets UHD apart is their extensive, customizable product portfolio which accommodates various industrial needs—from high-speed steel processing to intricate aerospace-grade alloys. Their diamond cutting tools exhibit enhanced hardness and edge retention, reducing wear rates by up to 25% compared to traditional tools. This extension in tool lifespan and performance reliability reduces machine downtime and maximizes throughput efficiency across different manufacturing sectors.

Leading automotive manufacturers in Germany and precision aerospace firms in Japan have integrated UHD’s diamond cutting tools to solve critical production challenges. In one notable case, a manufacturer reported a 15% reduction in blade replacement frequency and a 20% increase in cutting accuracy, leading to tighter tolerances in engine component fabrication. These improvements translated into significant cost savings and a more streamlined supply chain.

Another example from a metal fabrication plant in the United States showcased UHD’s ability to customize tooling solutions specifically for challenging composite materials. The tailored diamond tools improved cut surface finish quality and enhanced tool durability by over 30%, substantially minimizing unplanned maintenance and decreasing production stoppages.

The secret to UHD’s product superiority lies in its rigorous design methodology, which incorporates both material science and computational modeling. Each diamond cutting tool is developed through advanced simulation of cutting forces and thermal effects to optimize geometry for specific machining tasks. The company utilizes polycrystalline diamond (PCD) and synthetic diamond composites that provide exceptional hardness and thermal conductivity, significantly minimizing tool deformation and thermal damage.

Moreover, UHD implements strict quality control protocols and uses state-of-the-art equipment to ensure microscopic precision in tool manufacturing. Their innovative coating technologies enhance surface hardness by over 40%, substantially reducing tool wear and extending operational lifetime. These innovations permit UHD’s cutting tools to perform consistently under the most demanding industrial environments, including high-speed and high-temperature processes.

For procurement specialists aiming to boost manufacturing resilience and product precision, UHD offers a proven solution that mitigates downtime, cuts tooling costs, and enhances quality output. UHD’s commitment to innovation combined with their customizable product lines ensures that every tool is tailored to fulfill customer-specific industrial challenges.

The company's global reputation and documented case histories attest to its authoritative position as a trusted supplier for high-precision diamond cutting tools. Investing in UHD cutting tools is a strategic business decision that guarantees superior performance and significant economic advantages for manufacturers worldwide.