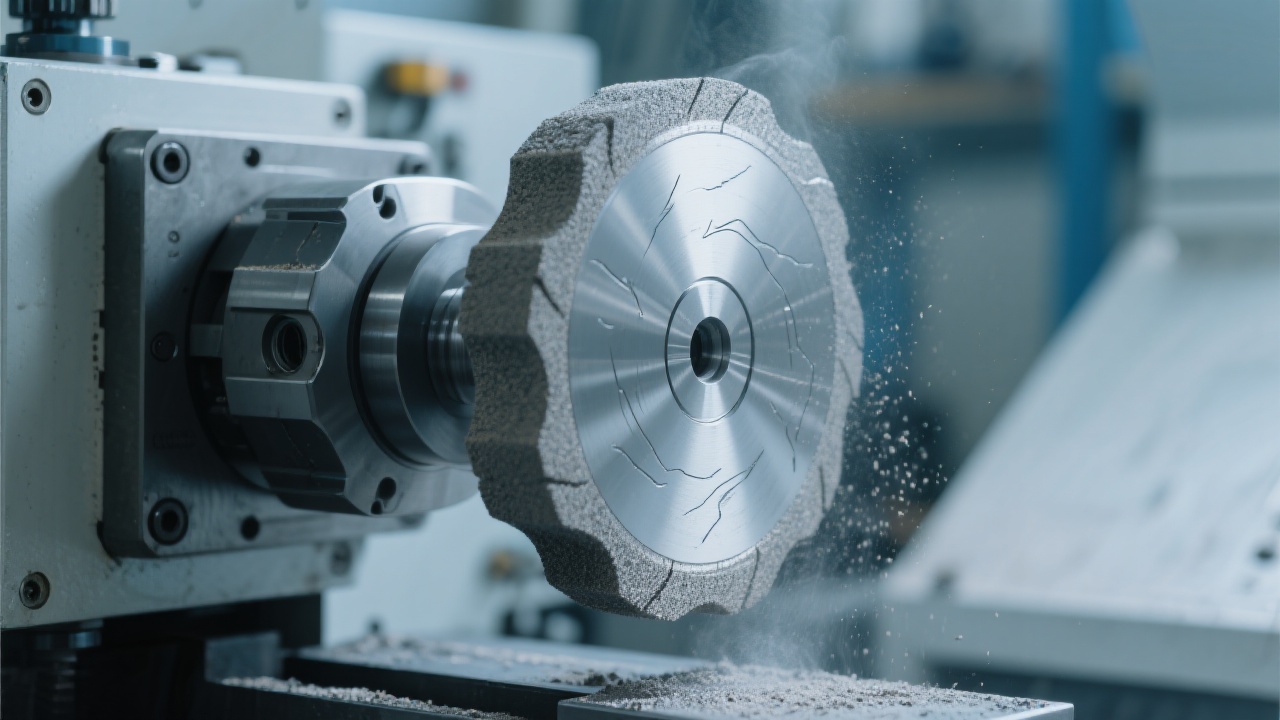

Traditional saw blades often encounter issues of high - frequency resonance during operation. From a physical perspective, the uneven distribution of mass on the saw blade and the inconsistent force exerted during cutting lead to this problem. When the saw blade rotates at high speed, the unbalanced mass creates centrifugal forces that cause the blade to vibrate. This vibration then generates noise, which not only affects the working environment but also reduces the cutting efficiency and quality. For example, in a typical stone - cutting operation, a traditional 400mm saw blade may generate noise levels up to 90 decibels, which is well above the recommended working noise level of 85 decibels.

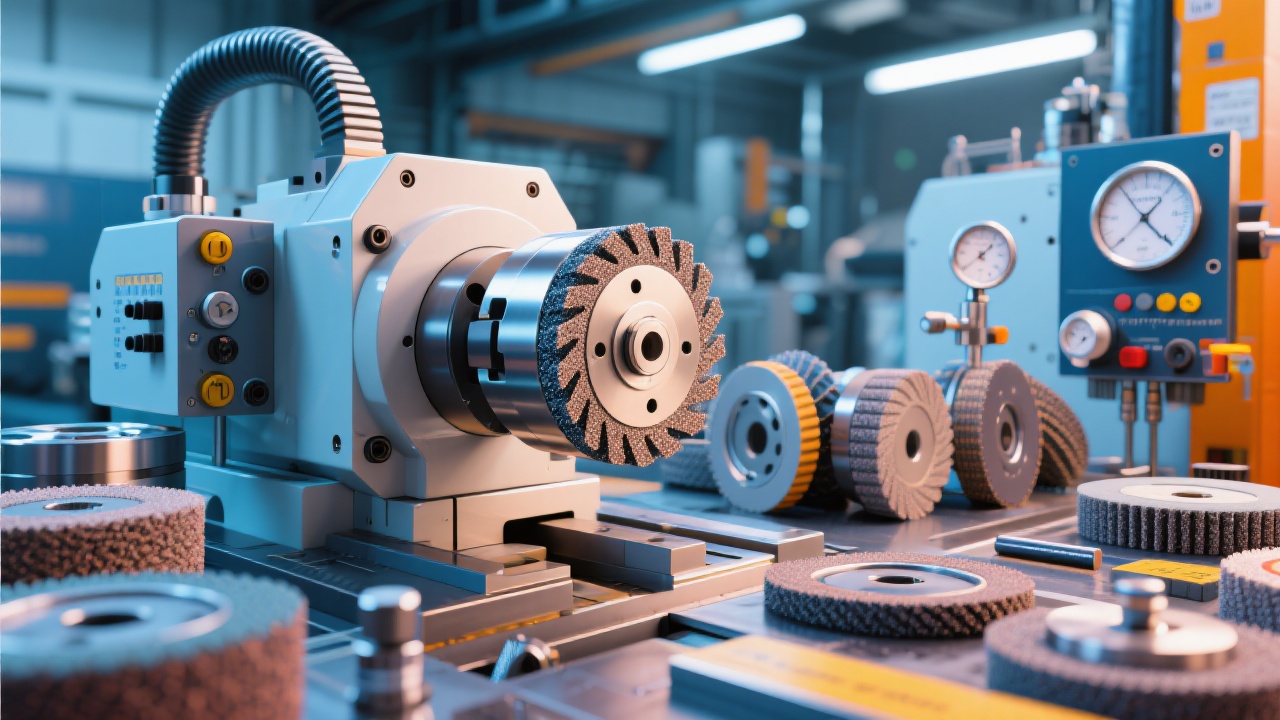

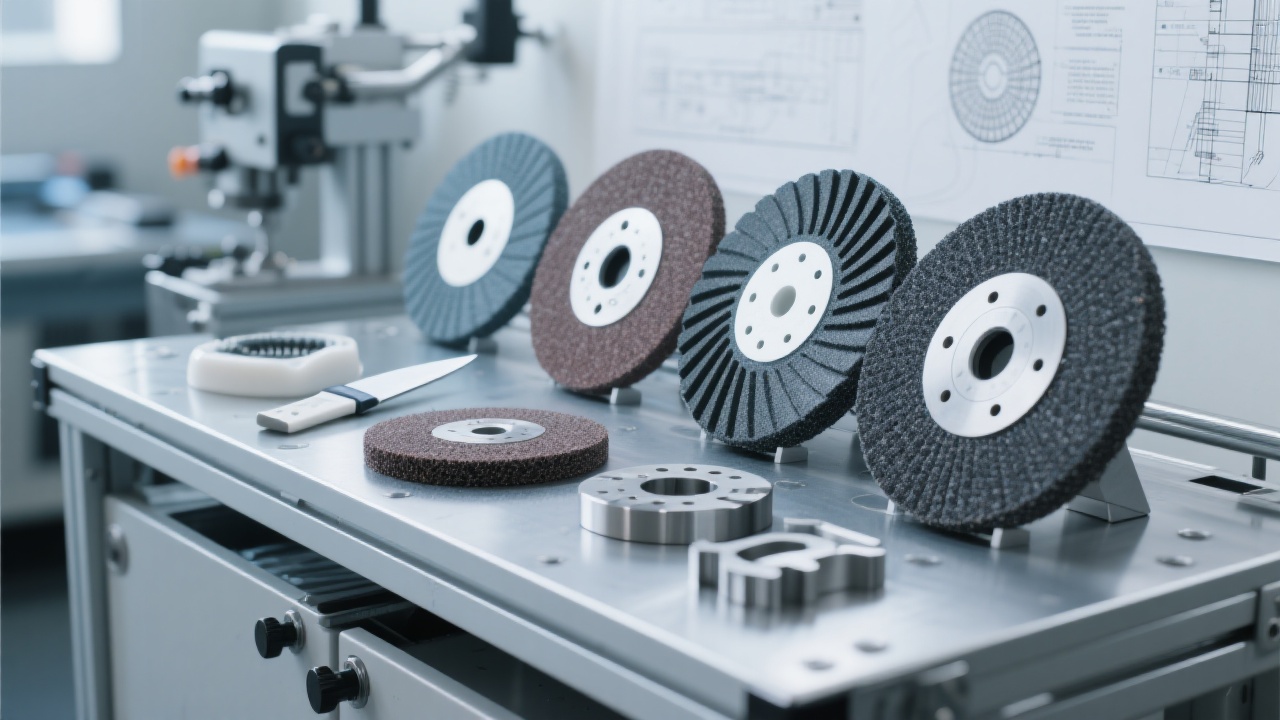

The 400H saw blade's segment arrangement density and angle play a crucial role in controlling the vibration frequency. By increasing the segment arrangement density, the saw blade can distribute the cutting force more evenly, reducing the concentrated force at a single point. The optimized angle of the segments also helps to guide the cutting chips away smoothly, further reducing the mechanical disturbance. For instance, a well - designed segment arrangement can reduce the vibration frequency by up to 30% compared to traditional saw blades.

The matrix of the 400H saw blade is designed to achieve a balance between rigidity and vibration absorption. A rigid matrix can maintain the shape of the saw blade during high - speed rotation, ensuring accurate cutting. At the same time, the matrix also has good vibration - absorption properties to reduce the transmission of vibration to the operator. The use of advanced materials and manufacturing processes helps to achieve this balance. For example, the matrix of the 400H saw blade can absorb up to 20% more vibration energy than a traditional matrix.

The brazing process of the 400H saw blade is carefully controlled to ensure high brazing strength and proper thermal stress release. High - strength brazing ensures that the segments are firmly attached to the matrix, preventing segment detachment during cutting. At the same time, the control of thermal stress release can reduce the internal stress of the saw blade, improving its stability. Through precise control of the brazing temperature and time, the 400H saw blade can achieve a brazing strength that is 15% higher than traditional saw blades.

In the stone processing industry, precision is of utmost importance. The 400H saw blade can achieve high - precision cutting with low noise and vibration. In a stone factory, when cutting high - quality marble, the 400H saw blade can maintain a cutting accuracy of up to ±0.1mm, while reducing the noise level to below 80 decibels. On the other hand, in a construction site, where the cutting operation is more rough, the 400H saw blade can still perform well. It can handle a variety of construction materials, such as concrete and bricks, with high efficiency. For example, in a construction project, the 400H saw blade can increase the cutting speed by 20% compared to traditional saw blades.

| Application Scenario | Noise Level (dB) | Cutting Accuracy (mm) | Cutting Speed Increase |

|---|---|---|---|

| Stone Processing | Below 80 | ±0.1 | N/A |

| Construction Site | Below 85 | N/A | 20% |

Front - line workers have valuable experience in using the 400H saw blade. As Zhang, a seasoned stone - cutter, said, "By listening to the sound of the saw blade during cutting, we can easily detect abnormal vibrations. If the sound becomes harsh, it usually means there is a problem with the saw blade or the cutting process." In addition, adjusting the fixture's stability can significantly extend the saw blade's service life. A stable fixture can reduce the additional vibration caused by the saw blade's movement, ensuring a more consistent cutting performance.

Are you tired of noisy and inefficient saw blades? The 400H saw blade offers a solution that combines high - performance cutting with low noise and vibration. By optimizing the design and manufacturing process, it can bring a new level of efficiency and comfort to your cutting operations. Don't miss out on this opportunity to transform your work. Click here to learn more about the 400H saw blade and how it can revolutionize your cutting experience.