In the field of construction and stone processing, the 400mm brazed diamond saw blade is a commonly used tool. However, the noise and vibration generated during the cutting process have always been a headache for operators. This article will deeply analyze how to effectively reduce the noise and vibration during the cutting process through the optimized design of the segment arrangement of the 400mm brazed diamond saw blade.

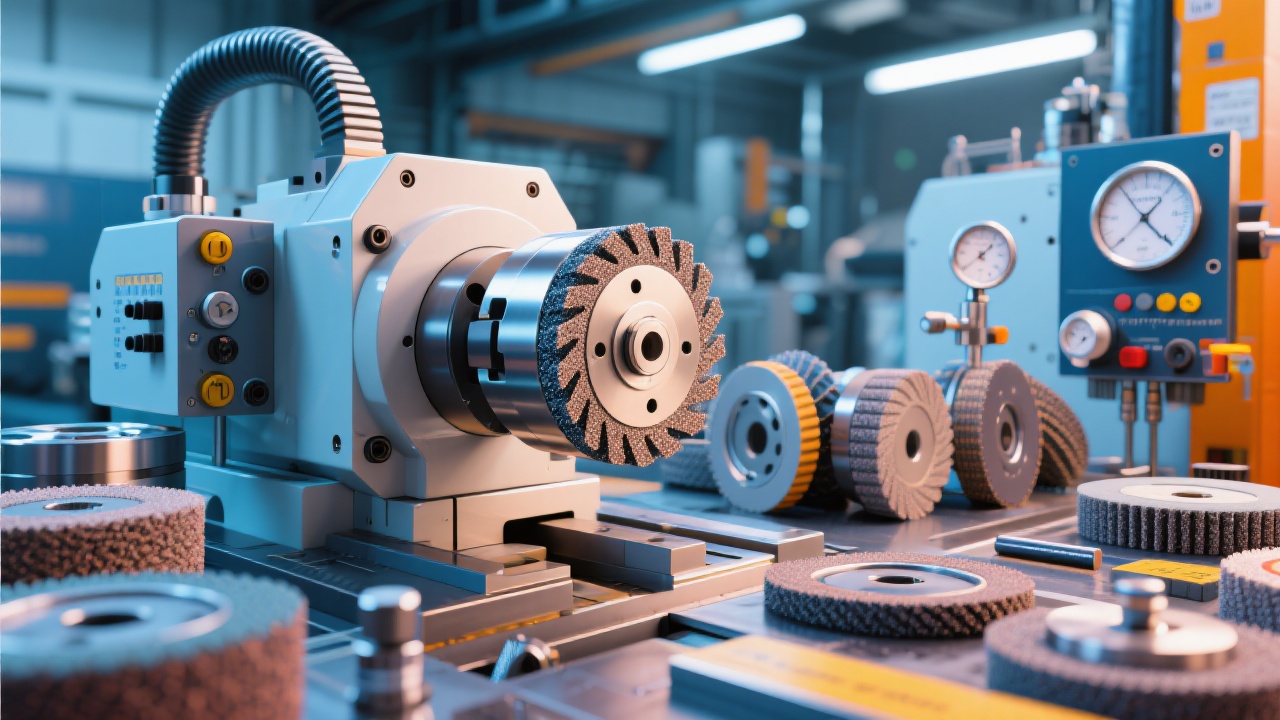

The density, angle, and spacing of the segment arrangement have a significant impact on the vibration of the saw blade. When the number of segments is too large, the mechanical disturbance during the cutting process will increase, resulting in more severe vibration and noise. On the contrary, if the number of segments is too small, the cutting efficiency will be affected. Generally speaking, for a 400mm saw blade, an appropriate number of segments is between 12 - 16.

The angle of the segments also plays a crucial role. A reasonable segment angle can reduce the resistance during the cutting process, thereby reducing vibration. For example, setting the segment angle at 15 - 20 degrees can effectively improve the cutting stability. In addition, the spacing between segments should be uniform to ensure a smooth cutting process. Uneven spacing may cause uneven stress on the saw blade, leading to increased vibration.

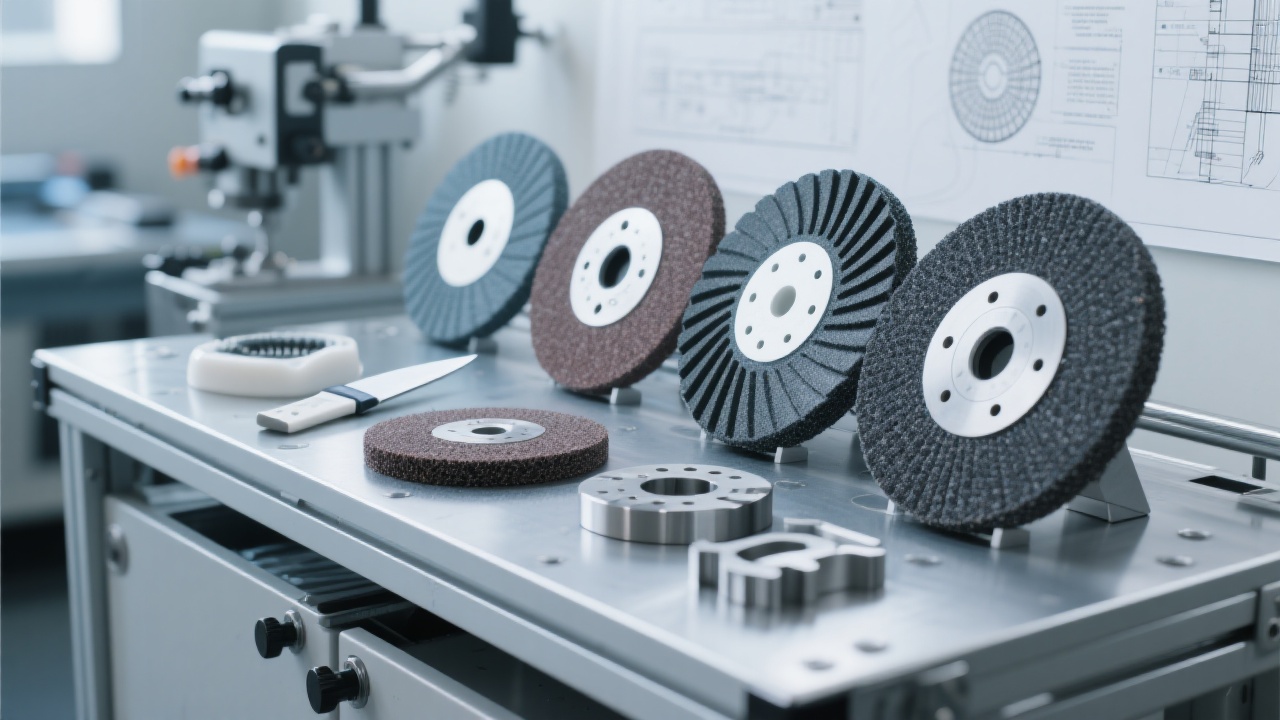

The base material of the saw blade needs to balance between rigidity and vibration - absorbing performance. A base material with high rigidity can ensure the stability of the saw blade during the cutting process, but it may also transmit more vibration. On the other hand, a base material with good vibration - absorbing performance can reduce noise, but its rigidity may be insufficient. Commonly used base materials such as high - strength alloy steel can be heat - treated to adjust its performance to achieve a balance between rigidity and vibration absorption.

Brazing technology has a direct impact on the mechanical strength and thermal stress release of the saw blade. A good brazing process can ensure a firm connection between the segments and the base material, improving the overall mechanical strength of the saw blade. At the same time, it can also effectively control the release of thermal stress during the cutting process, reducing the deformation and vibration of the saw blade. For example, using advanced vacuum brazing technology can ensure a more uniform and firm connection between the segments and the base material.

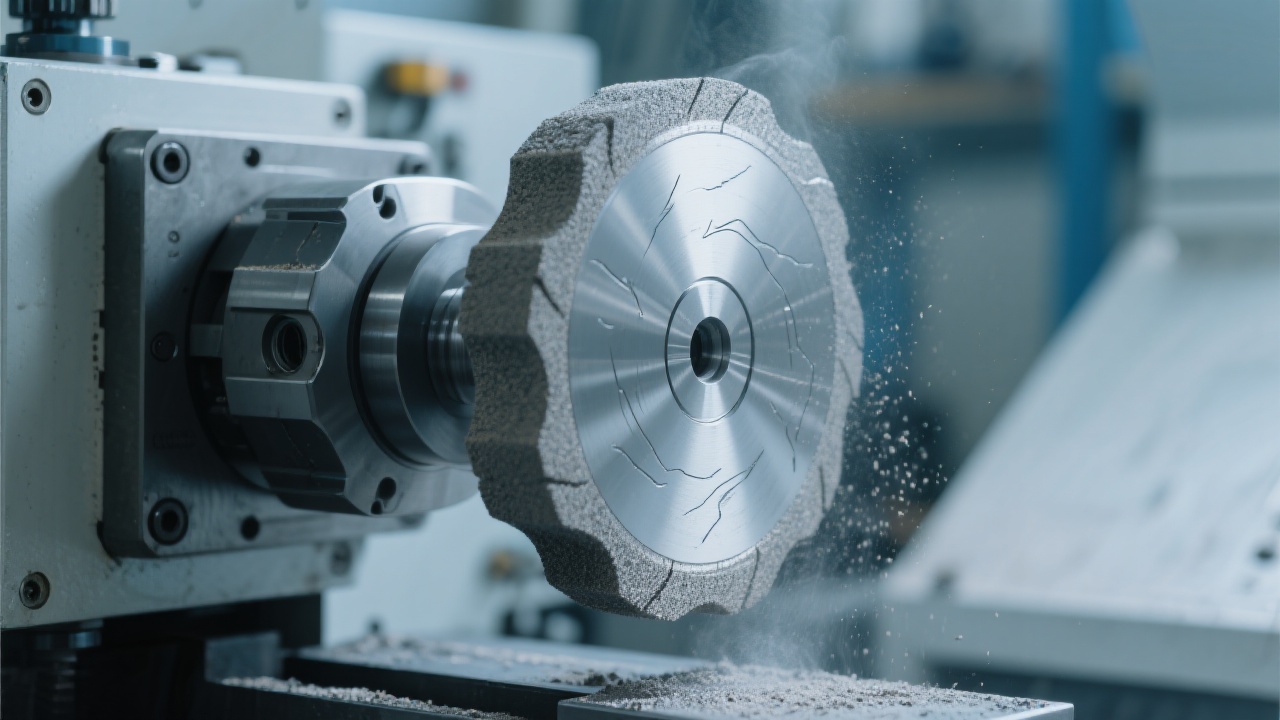

In actual construction projects, different parameter settings have a significant impact on the performance of the saw blade. For example, in a building construction project, when cutting concrete, setting the rotation speed at 3000 - 3500 rpm and the feed speed at 10 - 15 mm/min can achieve a relatively low - noise and stable cutting effect. In a stone processing plant, when cutting granite, adjusting the rotation speed to 2500 - 3000 rpm and the feed speed to 8 - 12 mm/min can effectively reduce vibration and noise.

Operators should also master some practical cutting skills. For example, they should pay attention to the stability of the fixture during the cutting process and adjust it in time when abnormal vibration signals are detected. They should also ensure that the cutting path is straight to avoid additional vibration caused by uneven cutting.

Are you eager to learn more details about optimizing the performance of 400mm brazed diamond saw blades? Click here to enter our technical column and explore more professional knowledge!