In the metal and stone processing industries, cutting efficiency directly impacts production throughput, tooling costs, and overall profitability. Many manufacturers still rely on outdated tools that wear out quickly under high-load conditions—leading to frequent downtime, inconsistent cuts, and rising operational expenses.

According to a 2023 industry survey by Machining Insights Global, over 67% of fabricators reported increased tool replacement frequency due to poor heat dissipation and inadequate bonding strength in conventional diamond segments. In one case from a Turkish marble quarry, operators experienced an average blade life of just 45 minutes per cut—resulting in 22% higher labor costs and 15% more material waste.

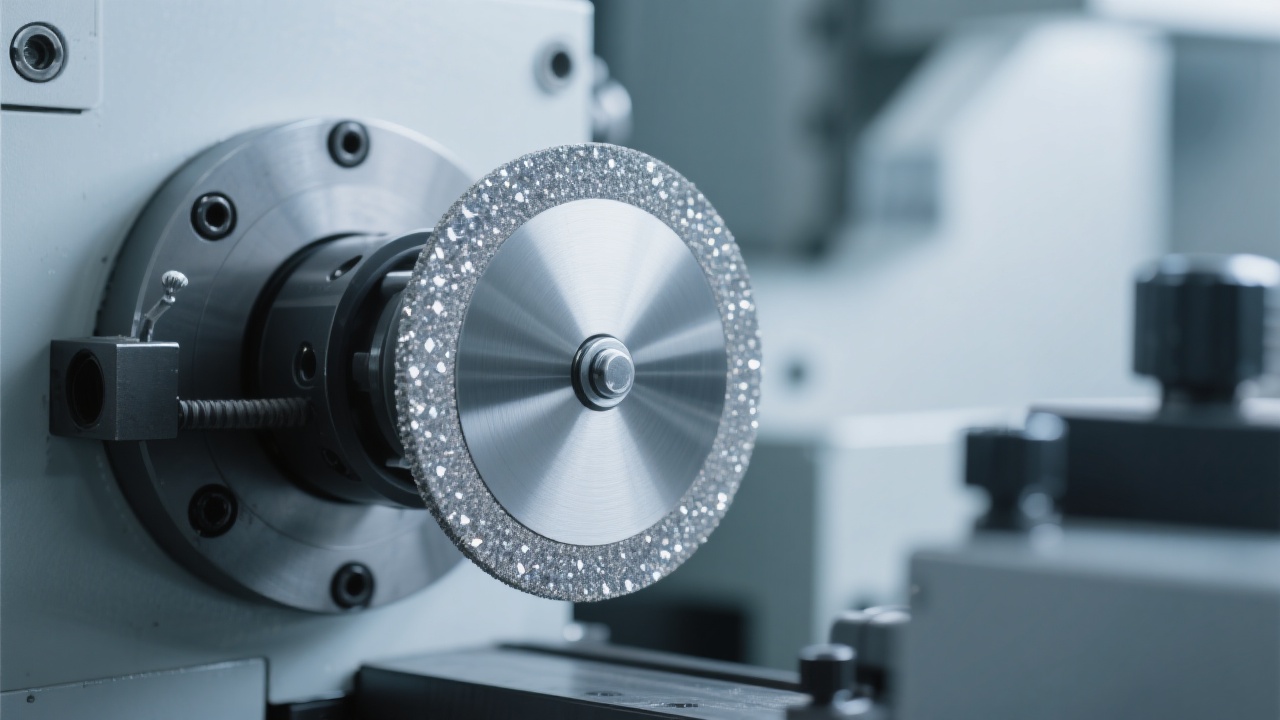

UHD Ultra-Hard Materials Co., Ltd. addresses these pain points with its advanced 150mm x 2.0mm diamond cutting disc, designed specifically for demanding applications in both metal and stone sectors. The key innovation lies in its vacuum brazing process, which ensures superior adhesion between the diamond grit and the steel core—reducing delamination risk by up to 83% compared to traditional soldered blades (based on lab tests conducted at Fraunhofer Institute).

| Feature | Standard Blade | UHD Diamond Disc |

|---|---|---|

| Blade Life (avg.) | ~45 mins | ~120 mins |

| Cutting Speed (m/min) | 2.1 | 3.8 |

| Heat Resistance | Low (degrades above 300°C) | High (stable up to 600°C) |

These improvements translate into real-world savings: A German automotive parts supplier using UHD’s discs reduced annual blade consumption by 62%, saving €18,000 in tooling alone—and boosted daily output from 120 to 190 units per machine.

Manufactured to meet ISO 13585 and EN 13478 standards, this tool is certified for use across diverse environments—from humid coastal regions in Southeast Asia to dry desert climates in the Middle East. Its robust design resists corrosion and maintains consistent performance even when exposed to aggressive coolants or abrasive dust.

Whether you're cutting stainless steel plates, granite slabs, or aluminum extrusions, UHD’s solution offers a proven balance of precision, durability, and cost-effectiveness—making it a top choice among global OEMs and job shops alike.

If your current cutting tools are causing delays, quality issues, or unnecessary spending, it’s time to explore what modern engineering can do. With UHD’s vacuum-brazed diamond technology, you’re not just buying a blade—you’re investing in long-term productivity gains.

Get Your Free Technical Evaluation Today – See How Much You Can Save