In the highly competitive landscape of industrial manufacturing, the demand for precise and efficient cutting solutions has never been more critical. Enterprises worldwide are seeking tools that not only deliver superior performance but also reduce operational costs and environmental impact. Among these, the ZS400H brazed diamond saw blade has emerged as a cutting-edge solution, demonstrating substantial advantages in durability, cutting precision, and eco-friendliness — factors essential for modern industrial operations.

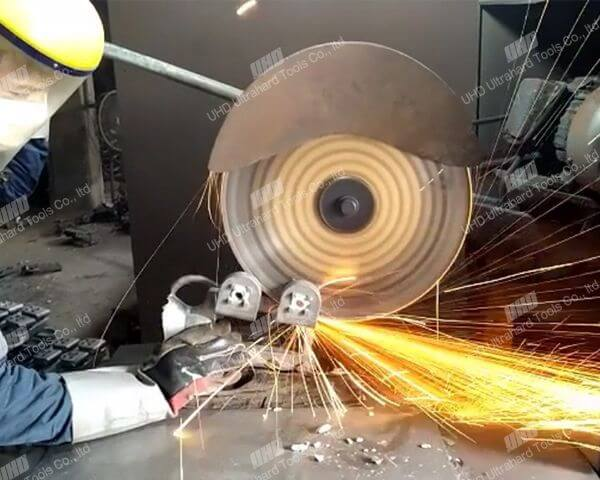

Industrial cutting processes often face multiple challenges: rapid blade wear, inconsistent cutting quality, and the need for equipment that ensures operator safety without compromising efficiency. The ZS400H saw blade, constructed with a high manganese steel base and a brazed diamond cutting edge, effectively overcomes these obstacles. This combination enhances the blade’s toughness and wear resistance, enabling it to maintain sharpness across extended usage cycles.

High manganese steel, known for its excellent impact resistance and strain hardening capability, forms the backbone of the ZS400H blade. The brazed diamond layer offers an optimized bond strength that withstands vibration and heat generated during high-speed cutting. This translates into prolonged blade life, reducing the need for frequent replacements and downtime.

Beyond mechanical robustness, the ZS400H diamond saw blade prioritizes sustainable production. The brazed bonding technique minimizes the use of hazardous materials common in traditional electroplated saw blades and eliminates toxic chemical waste typically associated with manufacturing. This complies with stringent global environmental regulations and appeals to companies committed to greener industrial practices.

According to recent industry studies, enterprises adopting diamond brazed blades witnessed a 30–40% improvement in cutting precision and a 25% reduction in blade-related downtime. This efficiency gain contributes directly to lower operational expenses and maximized throughput, positioning the ZS400H as a prime choice for high-volume manufacturers.

The versatility of the ZS400H saw blade makes it suitable across a variety of scenarios, including cutting through ceramics, reinforced composites, and hard metals. Its stable cutting performance directly leads to less generation of dust and debris, fostering safer working environments by reducing airborne particulates.

| Key Performance Attribute | ZS400H Saw Blade | Industry Average |

|---|---|---|

| Blade Life (hours) | 500+ | 300 |

| Cutting Precision (± mm) | ±0.02 | ±0.05 |

| Environmental Impact Score (lower is better) | 1.8 | 3.5 |

Leading manufacturers globally have recognized the ZS400H’s capability to boost production efficiency by up to 20%, citing its consistent performance across demanding cutting tasks. Safety officers highlight the blade's reduced dust emission during cutting, aligning with workplace health standards and decreasing respiratory hazards on the shop floor.

These testimonials, combined with technical data, offer a comprehensive picture of a product engineered to meet and exceed industrial cutting needs—balancing performance, safety, and environmental responsibility.

Selecting the right saw blade translates directly into measurable gains for businesses. The ZS400H diamond saw blade delivers:

For procurement teams and industry leaders seeking a trusted partner in cutting technology, the ZS400H represents a strategic investment in quality, efficiency, and sustainability.

Discover how the ZS400H brazed diamond saw blade can transform your production line with unmatched performance and eco-friendly operation.

Contact Us for a Consultation & Quote