Efficient cooling of 400mm diamond-welded saw blades plays a pivotal role in preventing premature blade wear and damage during municipal engineering operations. Understanding the nuanced differences between dry cutting and wet cutting techniques, coupled with strategic management of cooling parameters, directly impacts cutting performance, operational cost, and project timelines.

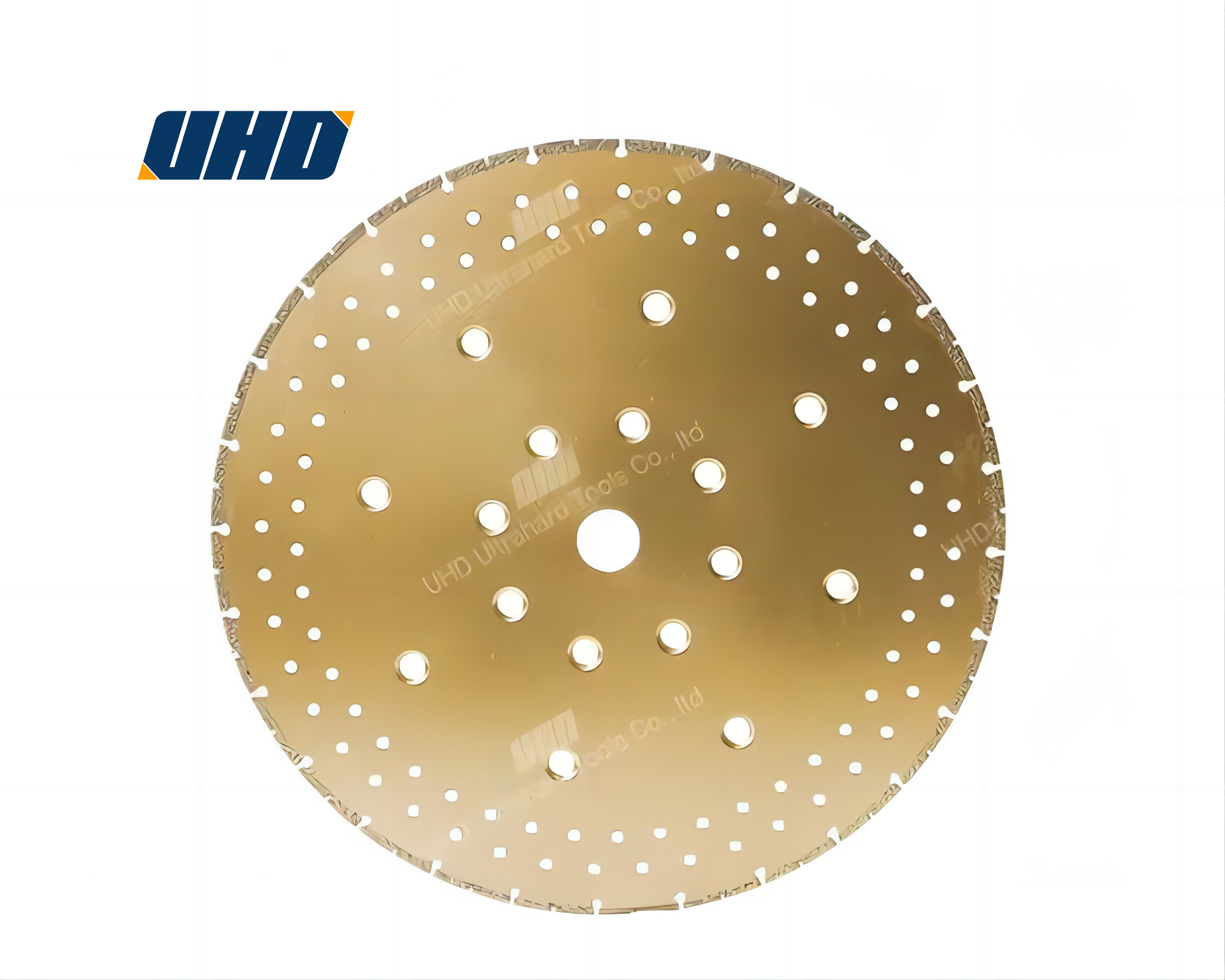

Diamond-welded blades engineered with 400mm diameters are prized for their durability and cutting precision on hard materials commonly encountered in municipal construction such as concrete, asphalt, and reinforced composites. The cutting edge—comprising diamond particles firmly bonded in a metal matrix—is susceptible to thermal stress generated by friction.

Excessive heat, if unchecked, causes blade warping, segment delamination, and accelerated tooth wear. Operational data from leading construction projects report a 35%-50% reduction in blade lifespan when cooling is inadequate, translating to significant financial and scheduling setbacks.

| Aspect | Dry Cutting | Wet Cutting |

|---|---|---|

| Cooling Mechanism | Air-cooling / natural convection | Water spray/liquid coolant application |

| Material Suitability | Best for softer, dry materials with low dust | Ideal for hard, abrasive materials generating dust |

| Heat Control Efficiency | Moderate; risk of localized overheating | High; effective heat dissipation at cutting interface |

| Dust Suppression | Low; requires additional dust management systems | Excellent; water suppresses airborne dust efficiently |

| Operational Requirements | Less infrastructure; portable, minimal water needed | Requires reliable water source and filtration |

| Cost Implications | Lower immediate costs; potential for higher blade replacement | Higher water and setup costs; longer blade life offsets expense |

Selecting the appropriate cooling method must factor in onsite conditions:

For example, a recent municipal road resurfacing project utilized wet cutting on 400mm diamond-welded blades with controlled water flow set at 4-6 liters per minute, achieving 20% faster cutting speeds and 35% blade lifespan extension compared to the previous dry-cutting method.

Dust control is integral given health regulations and site cleanliness standards. Wet cutting significantly suppresses dust emissions, enhancing worker safety and reducing cleanup time.

Thermal management is optimized by monitoring blade temperature using infrared sensors or embedded thermocouples in critical operations. Maintaining cutting temperature below 150°C (302°F) preserves diamond performance and adhesion quality.

Equipment longevity also benefits from proper coolant regulation—a consistent flow prevents motor overstrain and bearing degradation. Periodic inspection routines should emphasize checking for water contamination and coolant pH balance, which, when maintained around 6.5-7.5, ensures optimal blade integrity.

To assist field engineers and project managers in selecting the most suitable cooling mode, the following simplified flowchart aids rapid decision-making:

Affirmative answers to steps 1-3 favor wet cutting. Negative or constrained water scenarios indicate dry cutting with supplementary dust mitigation.

Our 400mm diamond-welded blades are engineered to perform optimally under both dry and wet cutting conditions, incorporating superior heat dissipation and dust reduction technologies verified through extensive field testing.

Clients benefit from:

Optimize your municipal engineering workflow by choosing a cooling solution paired with blades designed for longevity and performance. Discover how our specialized diamond blades adapt seamlessly to your cooling needs.