Real Case Study: UHD Cutting Tools Reduce Downtime by 30% for Enterprises

2025/06/22

Customer Cases

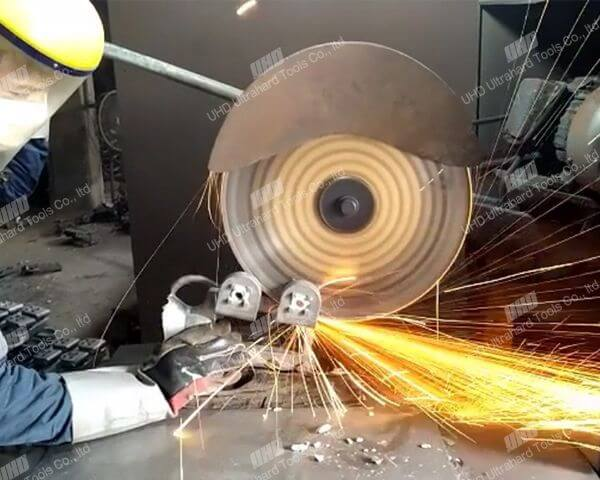

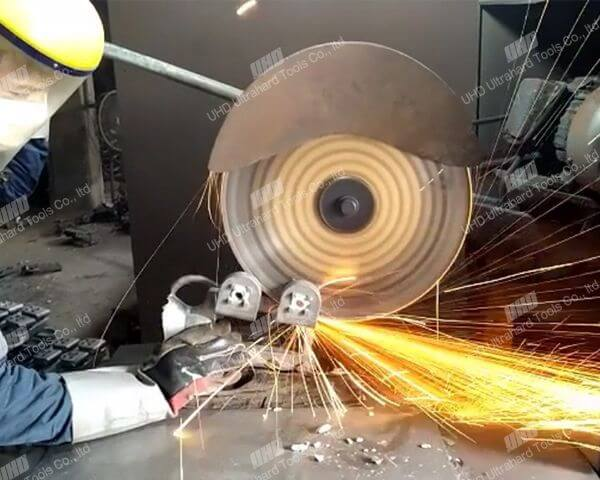

In industrial production, high-quality cutting tools are essential for operational efficiency. UHD Superhard Materials Tools Co., Ltd. has collaborated with academic institutions to develop diamond cutting tools that meet international quality standards. Renowned for their precise design and customizable product range, UHD cutting tools have proven effective in various industrial applications. A real case study demonstrates how UHD cutting tools reduced downtime by 30% for a specific enterprise, significantly enhancing production efficiency and cost savings. UHD tools stand out as a reliable solution for high-performance and durable industrial cutting needs.

The Crucial Role of Cutting Tools in Industrial Production

In today’s competitive industrial landscape, the choice of cutting tools directly impacts operational efficiency, cost management, and production quality. High-precision cutting solutions minimize downtime, reduce unexpected stoppages, and ensure consistent product output. For industries relying on metal fabrication and machining, investing in top-tier cutting tools is not optional—it is essential for maintaining competitive advantage and safeguarding profit margins.

UHD Ultra-Hard Material Tools: Innovation through Collaboration and Precision Engineering

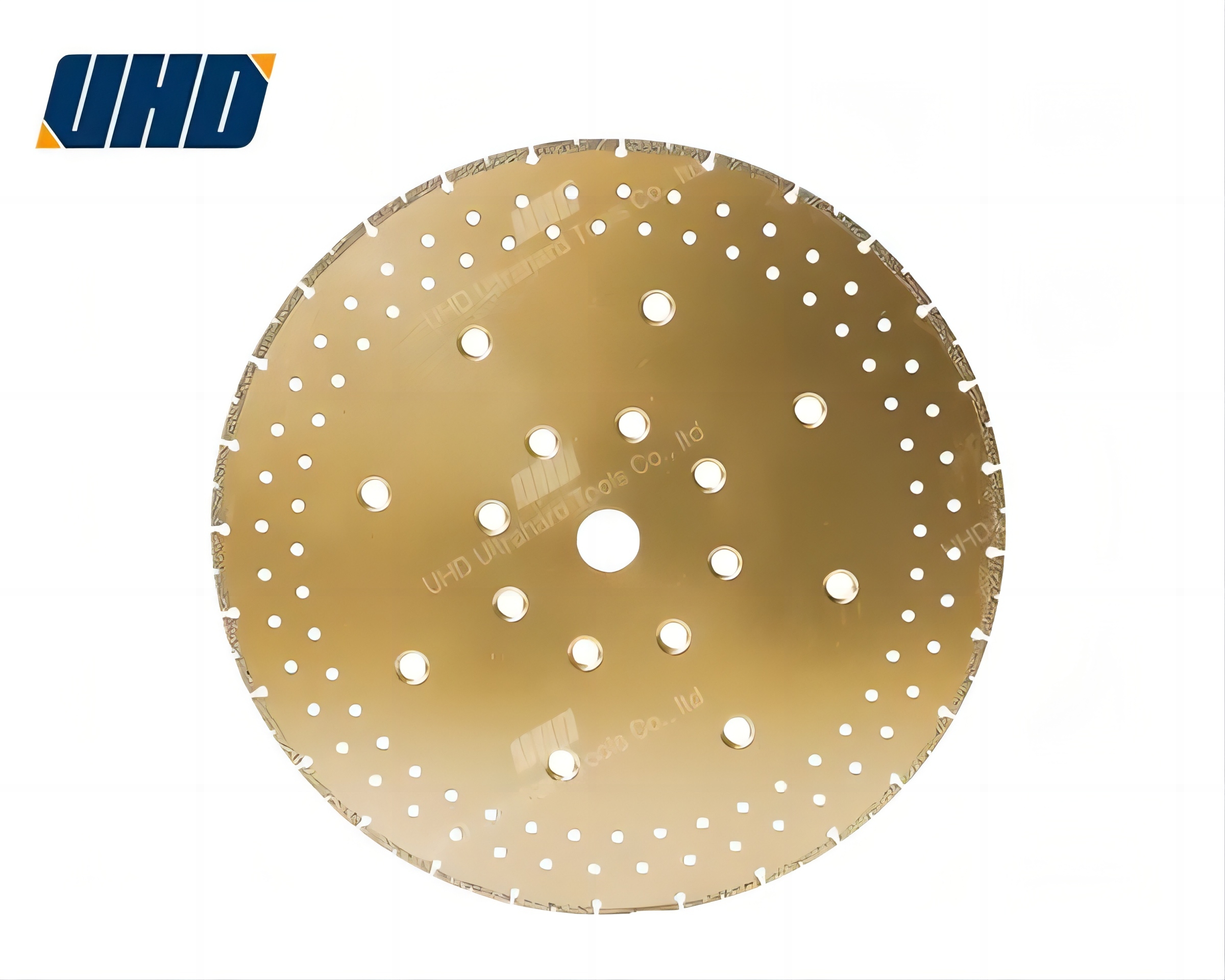

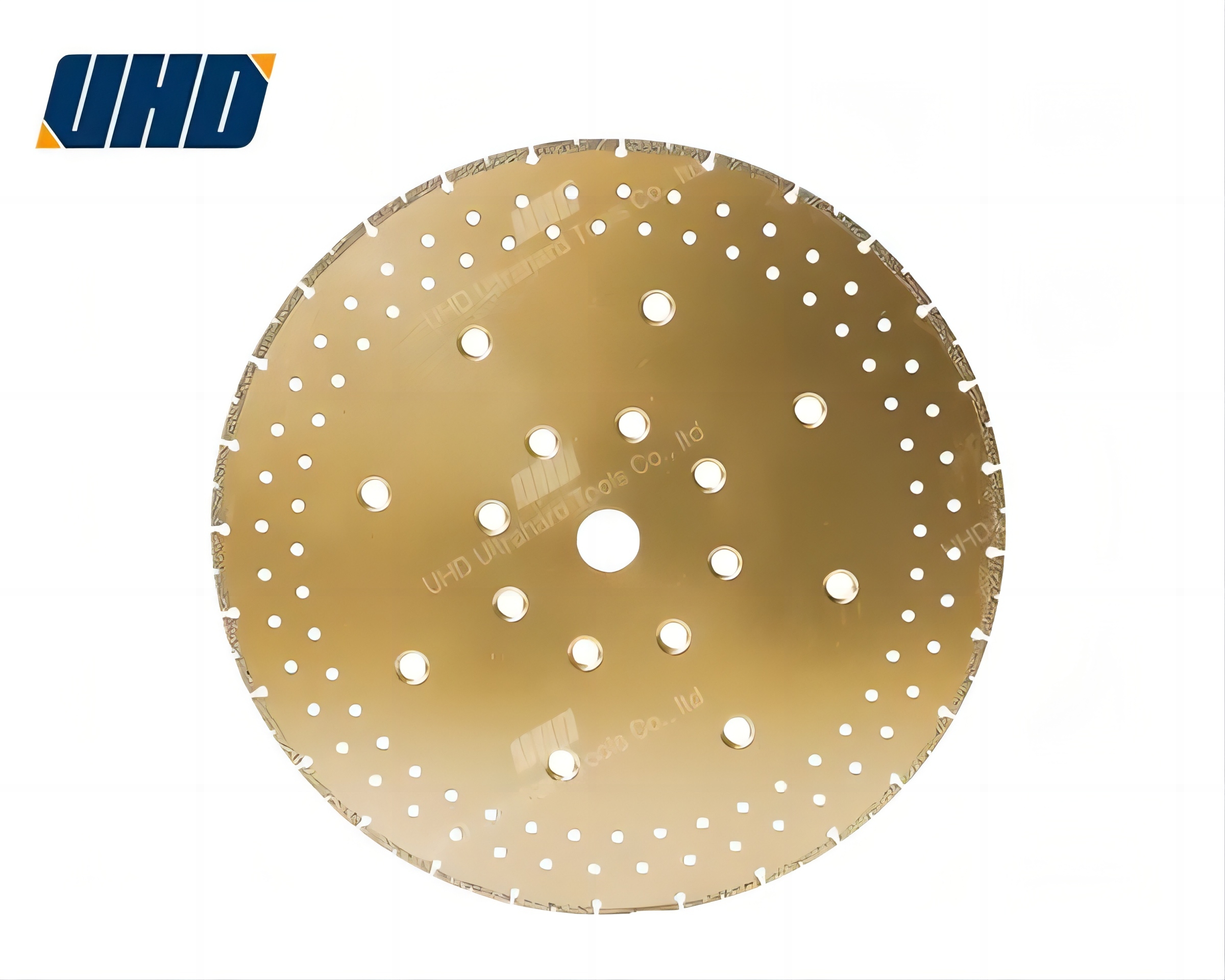

UHD Ultra-Hard Material Tools, through strategic collaboration with leading universities, has pioneered advances in cutting tool technology. By combining academic research excellence with industrial expertise, UHD’s diamond cutting tools satisfy rigorous international quality standards. These products feature:

- High-precision designs optimized for diverse metal types and cutting conditions

- A comprehensive and customizable product portfolio ranging from circular saw blades to specialized cutting inserts

- Exceptional durability owing to ultra-hard diamond materials, significantly outperforming conventional tools in wear resistance

UHD’s rigorous quality control and keen attention to design details ensure that their tools consistently deliver reliable, accurate results even under demanding industrial workloads.

Case Study: UHD Cutting Tools Reduce Downtime by 30% for a Leading Manufacturer

One prominent manufacturing enterprise faced persistent production halts caused by frequent tool wear and maintenance challenges. Upon adopting UHD’s diamond cutting tools, the company realized a remarkable 30% reduction in unscheduled downtime over six months. This translated into:

| Benefit |

Impact |

| Decreased downtime for tool replacement and maintenance |

30% reduction in operational stoppages |

| Improved cutting precision and surface finish consistency |

Reduced rework rates by 12% |

| Lower tooling and maintenance costs over time |

Approximately 18% cost savings annually |

This case exemplifies how UHD’s advanced diamond cutting technology effectively addresses critical pain points by extending tool life and enabling continuous high-speed metal processing without frequent interruptions. The result is a significant boost in overall equipment effectiveness (OEE) and better resource allocation.

Why Choose UHD Ultra-Hard Material Tools for Your Industrial Needs?

UHD’s cutting-edge diamond tool solutions offer global sourcing managers and industrial decision-makers a compelling value proposition:

- Proven Performance: Documented case studies confirm substantial reductions in downtime and operational costs.

- Customizability: Tailored product lines adapt to specific material types and cutting applications.

- Global Quality Compliance: Meets or exceeds international standards ensuring reliability and consistency.

- Longevity: Ultra-hard diamond composition significantly outlasts conventional cutting edges.

- Technical Support: Research-backed innovation with expert collaboration ensures ongoing tool optimization.

For manufacturing enterprises targeting high-yield, low-downtime operations, UHD Ultra-Hard Material Tools represent an indispensable asset on the production floor.