In metal fabrication and stone processing, downtime from frequent blade changes, inconsistent cuts, and excessive dust aren’t just minor inconveniences—they’re major profit drains. At a mid-sized mechanical factory in Zhengzhou, China, these issues were costing over $12,000 monthly in wasted materials, labor, and cleanup.

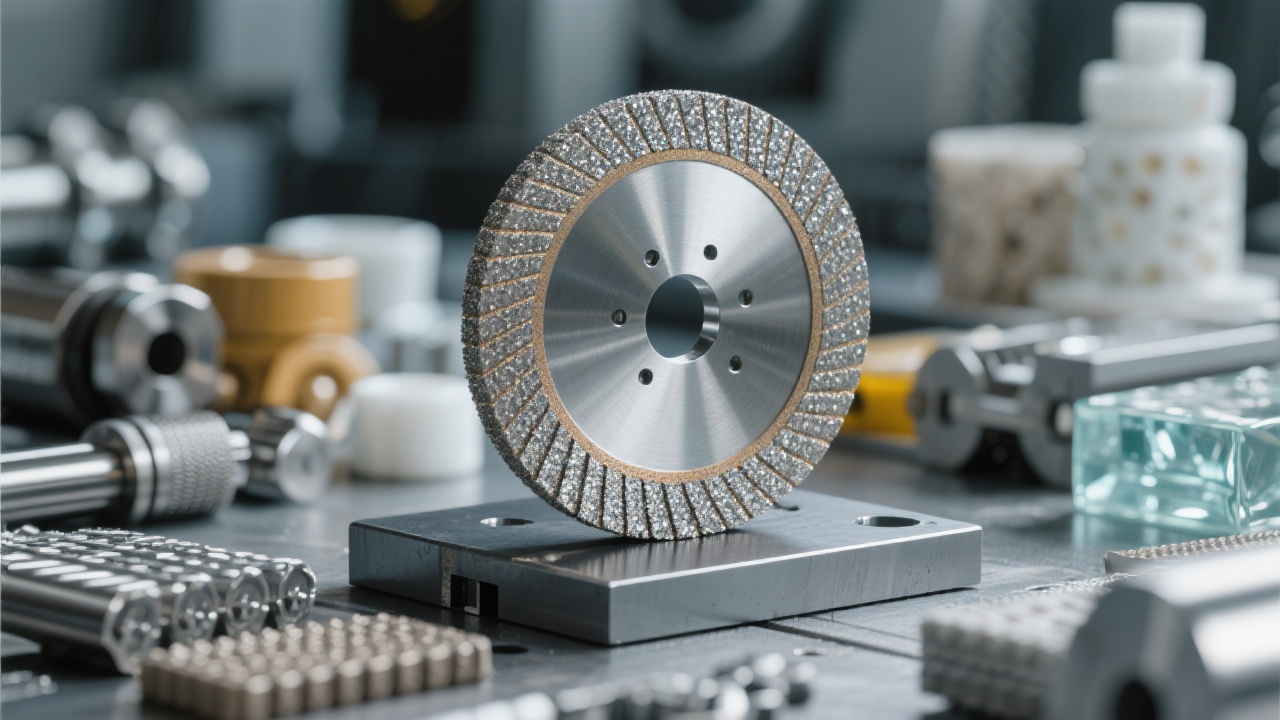

That changed when they switched to UHD Welded Diamond Cutting Discs (Model 400) from Henan Youde Superhard Tools Co., Ltd.—a solution backed by ISO 9001-certified quality control and engineered for real-world toughness.

| Performance Metric | Traditional Resin Blade | UHD Diamond Blade (Model 400) |

|---|---|---|

| Average Lifespan | ~8 hours per disc | ~14 hours per disc (+75%) |

| Dust Emission Level | High (requires PPE + ventilation) | Low (up to 40% reduction) |

| Cut Quality Consistency | Frequent burrs, uneven edges | Smooth finish, minimal post-processing |

The factory manager, Mr. Li, shared his experience: “Before UHD, we were replacing blades every 8–10 hours. Now, with one disc lasting up to 14 hours under heavy load, our team spends less time changing tools and more time producing.”

It’s not just marketing—it’s science. The UHD blade uses ultra-fine diamond grit bonded to a high-manganese steel base, which resists deformation even at high temperatures. Combined with an optimized tooth geometry, it ensures consistent cutting force across the entire disc surface—not just the edge.

This design reduces vibration, minimizes heat buildup, and prevents premature wear—key factors that make traditional resin blades fail after only a few hours of continuous use.

For operators, this means fewer interruptions, less fatigue from handling hot or damaged blades, and cleaner workspaces. For managers, it translates into lower operational costs and higher throughput—especially important in industries like construction, automotive, and CNC machining where precision matters.

One customer reported saving over $3,600/month in direct material and labor costs simply by switching to UHD. That’s not just cost-cutting—it’s strategic investment in production stability.

Whether you're running a small workshop or managing a large-scale manufacturing plant, upgrading your cutting tools can be one of the fastest ROI projects you’ll ever undertake.

Ready to see how UHD can transform your workflow? Don’t just take our word for it—see what real users are saying.

Experience the UHD Difference – Get Your Free Sample TodayPublished by Henan Youde Superhard Tools Co., Ltd. | All rights reserved | Validated by real-world results, not promises.