When it comes to choosing a concrete cutting saw blade, you need to focus on three core dimensions: material hardness, cutting depth, and operating environment (dry cutting or wet cutting). Material hardness directly affects the wear rate of the saw blade. For example, cutting high - strength concrete requires a saw blade with better wear - resistance. The cutting depth determines the size and type of the saw blade. If you need to cut deeper, a larger - diameter saw blade might be more suitable. The operating environment, whether it's dry cutting or wet cutting, also has a significant impact on the performance and lifespan of the saw blade.

The 400mm diameter saw blade has a wide range of applications in the construction industry. In high - rise building demolition projects, it can quickly and accurately cut through concrete structures, improving the efficiency of demolition. For instance, in a recent high - rise building demolition project, the use of 400mm saw blades increased the cutting efficiency by 30% compared to smaller - diameter saw blades. In floor treatment, it can precisely cut the floor to meet the requirements of different floor finishes. In bridge maintenance, it can be used to repair damaged concrete parts of the bridge, ensuring the safety and stability of the bridge structure.

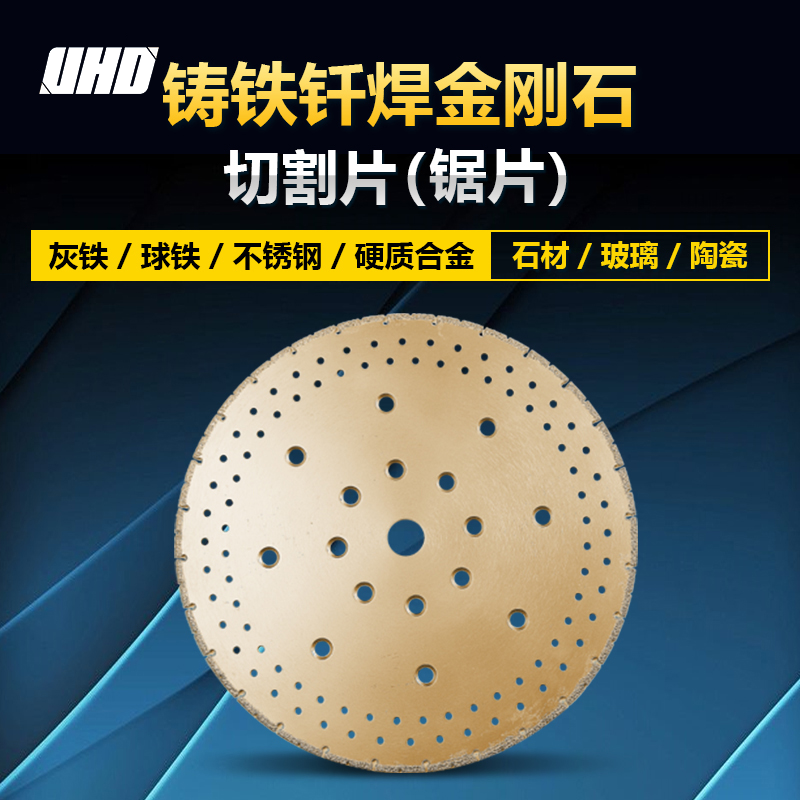

There are significant differences between brazing and traditional welding in terms of wear resistance, bonding strength, and lifespan. Brazed diamond saw blades, like the 400H brazed diamond saw blade, have a higher bonding strength between the diamond and the substrate. This means they can better withstand the impact and friction during cutting, resulting in a longer lifespan. In a comparative test, brazed saw blades showed 50% less wear than traditional welded saw blades after cutting the same amount of concrete. The better wear resistance also means that brazed saw blades can maintain a sharp cutting edge for a longer time, improving cutting efficiency.

You can judge the wear state of the cutter head through visual inspection, tactile feeling, and changes in cutting efficiency. Visually, if the cutter head shows obvious signs of wear, such as a rounded edge or a significant reduction in the height of the cutter head, it may need to be replaced. By touching the cutter head, you can feel if there are any abnormal bumps or smooth areas, which may indicate uneven wear. A decrease in cutting efficiency, such as slower cutting speed or more difficult cutting, can also be a sign of cutter head wear. Below is a simple table showing the wear levels of the cutter head:

| Wear Level | Visual Sign | Suggestion |

|---|---|---|

| Slight | Slight dulling of the edge | Continue to use, but monitor closely |

| Moderate | Visible wear on the edge, some reduction in height | Consider replacement soon |

| Severe | Rounded edge, significant reduction in height | Replace immediately |

Dry cutting and wet cutting each have their own advantages and applicable conditions. Dry cutting is suitable for environments where water is not available or where water - free cutting is required. However, it generates more heat, which can accelerate the wear of the saw blade. Wet cutting, on the other hand, can effectively reduce the temperature of the saw blade, extending its lifespan. When choosing wet cutting, you need to ensure that the cooling water supply is stable and that the water - spraying device is properly configured. Safety is also crucial. For example, when using wet cutting in electrical - rich environments, you need to take appropriate insulation measures.

According to real - world construction data and user feedback, using the right saw blade and cooling method can significantly improve cutting efficiency and extend the lifespan of the saw blade. For example, in a large - scale floor treatment project, by using 400H brazed diamond saw blades and the appropriate wet - cutting method, the saw blade's lifespan was extended by 40%, and the overall project cost was reduced by 20%.

The 400H brazed diamond saw blade is an excellent choice for your construction projects. It is designed to meet the needs of various construction scenarios, with high wear - resistance, strong bonding strength, and a long lifespan. It can help you improve cutting efficiency and ensure the safety of your operations. If you want to enhance the cutting efficiency and safety of your projects, click here to learn more about the 400H brazed diamond saw blade.

Q: How often should I replace the cutter head?

A: It depends on the cutting material, cutting frequency, and operating environment. Generally, if you notice a significant reduction in cutting efficiency or obvious wear on the cutter head, it's time to replace it.

Q: Can I use a 400mm saw blade for dry cutting all the time?

A: It's not recommended. Although dry cutting is possible, it can generate a lot of heat, which may damage the saw blade. It's better to alternate between dry and wet cutting or use wet cutting as much as possible in appropriate environments.