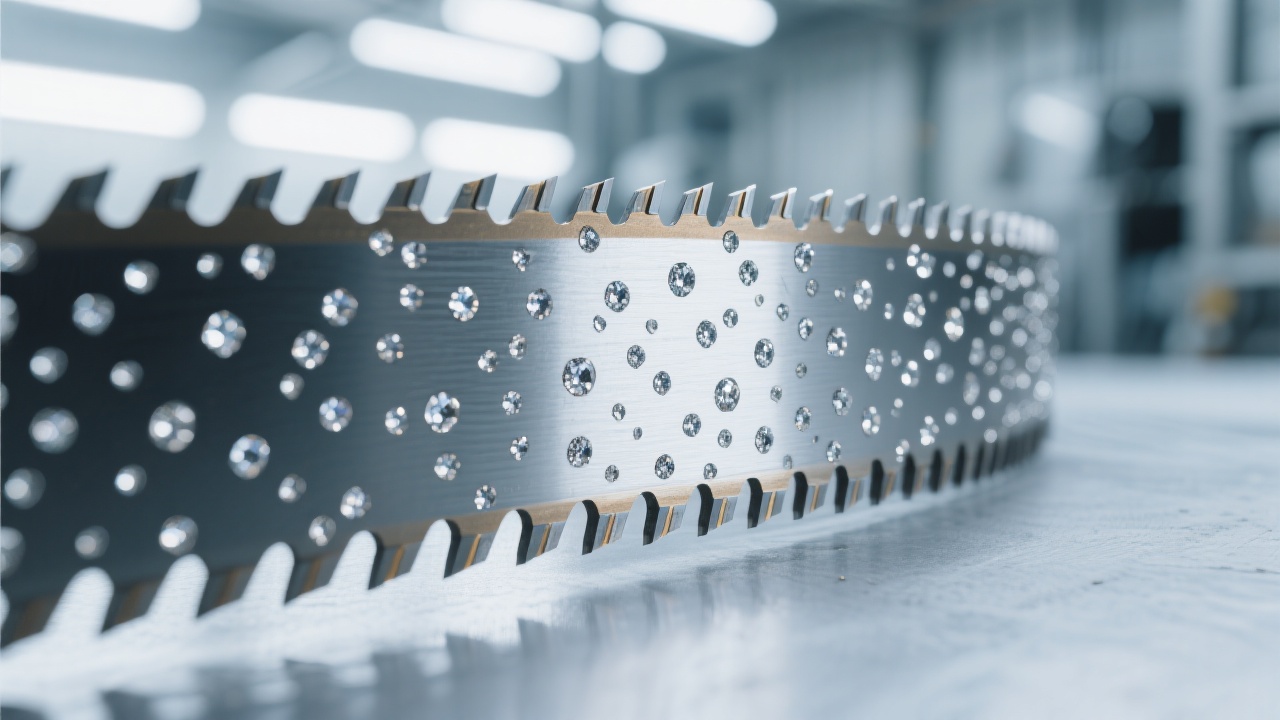

In the realm of stone processing and construction projects, the 400mm brazed diamond saw blade plays a pivotal role. This article delves deep into optimizing the cutting efficiency and stability of such saw blades, offering a technical - driven practical guide for professionals.

The design of the saw blade, including the arrangement of the segments, the selection of the base material, and the brazing process, has a profound impact on cutting performance. The arrangement of the segments affects the contact pattern between the saw blade and the material being cut. A well - designed segment arrangement can distribute the cutting force evenly, reducing noise and vibration. For example, a staggered segment arrangement can sometimes provide better cutting efficiency compared to a linear one. In some tests, a well - arranged segment design can reduce noise levels by up to 15% and vibration by 20%.

The choice of base material is also crucial. Different base materials have different mechanical properties, such as strength, toughness, and elasticity. Matching the base material with the segment characteristics can enhance the overall performance of the saw blade. For instance, a high - strength steel base can better withstand the stress during cutting, reducing the risk of blade deformation and improving the stability of the cutting process.

The brazing process is another key factor. A well - controlled brazing process ensures a strong bond between the segments and the base, which is essential for maintaining the integrity of the saw blade during cutting. Poor brazing can lead to segment detachment, increased vibration, and reduced cutting efficiency.

In actual construction, the rotational speed and feed rate are two important parameters that need to be carefully configured. In stone processing plants, where the materials are usually more homogeneous, a higher rotational speed combined with a moderate feed rate can often achieve better cutting results. However, in construction sites, where the materials may be more complex and uneven, a lower rotational speed with a slower feed rate may be required to ensure cutting stability.

Let's take a real - life construction case. In a large - scale building project, when cutting granite, the original cutting parameters led to excessive noise and vibration, which not only affected the workers' comfort but also reduced the service life of the equipment. After adjusting the rotational speed from 3000 rpm to 2500 rpm and the feed rate from 100 mm/min to 80 mm/min, the noise level was significantly reduced, and the vibration was also under control. The cutting efficiency was maintained, and the equipment life was extended by approximately 30%.

During the cutting process, abnormal vibration can be a sign of various problems. For example, uneven segment wear, misaligned saw blades, or loose fixtures can all cause abnormal vibration. By carefully observing the vibration pattern, such as the frequency and amplitude, workers can identify the root cause of the problem. Once the problem is identified, corresponding adjustment measures can be taken. For example, if the vibration is caused by a loose fixture, tightening the fixture can effectively reduce the vibration.

In conclusion, by optimizing the saw blade design, configuring the cutting parameters correctly, and mastering the techniques for identifying and adjusting vibration abnormalities, professionals can achieve more efficient, quieter, and more stable cutting operations. This not only improves the production efficiency but also enhances the construction quality.

If you want to explore more in - depth technical knowledge about brazed diamond saw blades and learn more practical cutting parameter setting skills, click to enter our technical column.