In the realm of industrial manufacturing, cutting saw blades play a pivotal role. They are essential tools for shaping and processing various materials, from metals to composites. The efficiency and quality of a saw blade can significantly impact the overall production process, affecting both the cost and the quality of the final products. A high - performance saw blade can reduce production time, minimize waste, and enhance the precision of cuts, all of which are crucial factors for manufacturers striving to stay competitive in the global market.

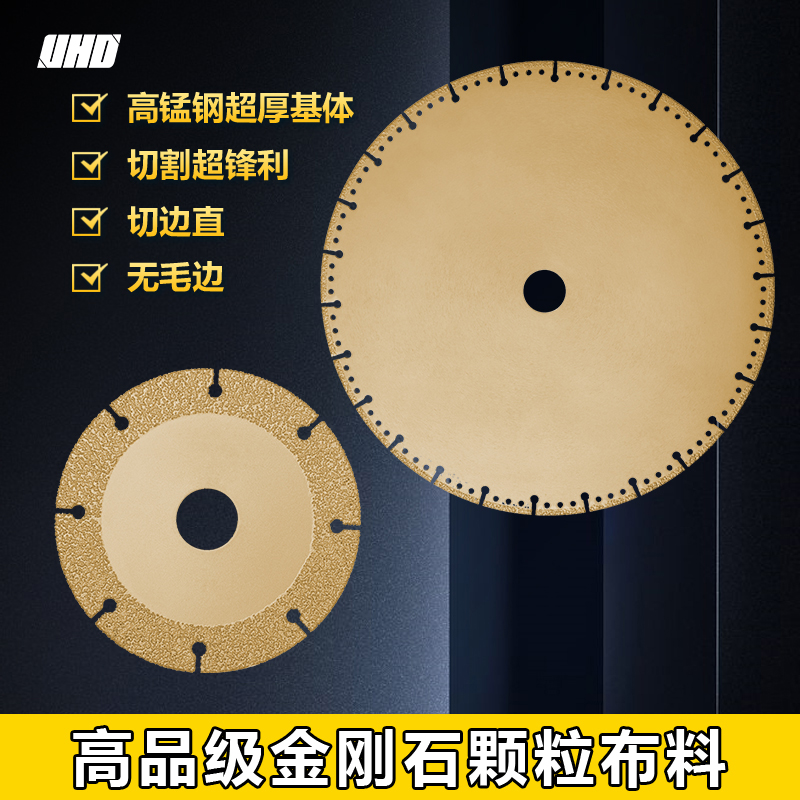

The ZS400H brazed diamond saw blade, introduced by UHD Superhard Materials Tools Co., Ltd., is a state - of - the - art cutting tool. It is engineered with advanced diamond particles, which are known for their exceptional hardness and wear - resistance. These diamond particles are precisely bonded to a super - thick high - manganese steel substrate, ensuring a strong and stable connection. This combination of high - quality materials and advanced bonding technology enables the saw blade to maintain its sharpness even under heavy - duty cutting conditions.

The saw blade also features a precisely designed tooth profile. This design is optimized to provide smooth and efficient cutting, reducing the amount of force required during the cutting process. Additionally, the unique tooth geometry helps to dissipate heat effectively, preventing overheating and extending the lifespan of the saw blade.

When compared to traditional resin saw blades, the ZS400H offers several significant advantages. Firstly, in terms of wear - resistance, the ZS400H can last up to 300% longer. Traditional resin saw blades tend to wear out quickly, especially when cutting hard materials such as gray cast iron, ductile iron, stainless steel, and hard alloys. The ZS400H, on the other hand, can withstand the rigors of continuous cutting, reducing the frequency of blade replacements and thus lowering the overall operating costs.

Secondly, the ZS400H is much sharper. Its advanced diamond particles can cut through materials more easily, resulting in cleaner and more precise cuts. This sharpness also translates into higher cutting speeds, which can increase production efficiency by up to 200%. In contrast, traditional resin saw blades may struggle to maintain a consistent cutting speed, leading to uneven cuts and longer production times.

| Features | ZS400H Saw Blade | Traditional Resin Saw Blade |

|---|---|---|

| Wear - resistance (Lifespan) | Up to 300% longer | Shorter |

| Sharpness | High | Low |

| Cutting Speed | Up to 200% faster | Slower |

In real - world industrial applications, the ZS400H has proven its worth. For example, in the automotive manufacturing industry, where precision cutting of metal components is essential, the ZS400H can provide clean and accurate cuts, reducing the need for secondary processing. In the aerospace industry, which requires high - precision cutting of advanced materials, the saw blade's ability to maintain sharpness and precision over long periods makes it an ideal choice.

The ZS400H is not only a high - performance tool but also an environmentally friendly one. It produces significantly less dust during the cutting process compared to traditional saw blades. This is not only beneficial for the health of workers but also helps to meet environmental regulations. Moreover, its high efficiency means less energy consumption per cut, contributing to a more sustainable manufacturing process.

By offering superior performance, longer lifespan, and environmental benefits, the ZS400H saw blade can greatly enhance the competitiveness of manufacturing enterprises. It allows manufacturers to produce high - quality products more efficiently, at a lower cost, and in an environmentally friendly manner. This is particularly important in today's global market, where customers demand both quality and sustainability.

Don't miss out on the opportunity to revolutionize your cutting operations. Upgrade to the ZS400H brazed diamond saw blade today and experience the difference it can make in your manufacturing process. Click here to learn more and place your order!