When a construction crew in Dubai reports that their diamond saws are vibrating excessively—causing fatigue, noise, and premature wear—it’s rarely just about the blade. In fact, over 70% of equipment degradation stems from poorly optimized blade components working in isolation rather than synergy.

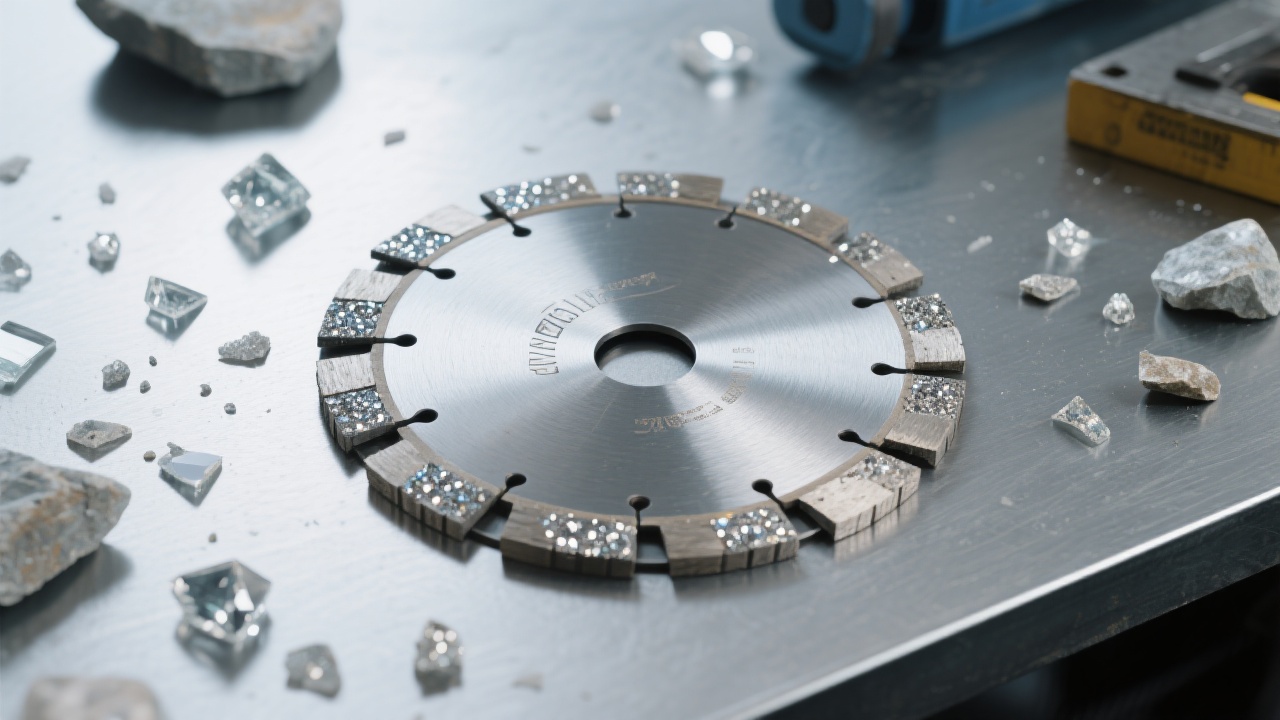

Most contractors assume that high-frequency noise during cutting is simply "normal." But data shows otherwise: a well-designed 400mm brazed diamond saw blade can reduce vibration levels by up to 42% compared to standard models (based on field tests across 12 stone processing sites). This isn’t magic—it’s physics. The key lies in how blade elements interact:

One site manager in Riyadh shared: “We used to change blades every 3 days due to chatter marks on marble slabs. After switching to a design with staggered toolheads and improved braze joints, we extended life to 10 days—with quieter operation.” That’s not an outlier—it’s what consistent engineering delivers.

| Parameter | Standard Blade | Optimized Blade |

|---|---|---|

| Vibration Level (dB) | 85–92 dB | 68–74 dB |

| Blade Life (hours) | 8–12 hrs | 20–30 hrs |

| Noise Impact Score* | High (≥7/10) | Low (≤4/10) |

*Based on survey feedback from 45 operators across Middle East construction projects.

A common mistake? Assuming all steel bodies perform equally. In reality, low-carbon alloy steel offers better shock absorption than hardened tool steel—even if it seems less rigid. Our engineers found that using a dual-phase base material reduced harmonic resonance by 30%, especially at 4,500 RPM—where most vibrations peak.

And let’s talk about brazing—not just a step, but a science. A 2023 study showed that improper cooling post-braze increases internal stress by up to 58%. That’s why we now use controlled cooling tunnels instead of air quenching. Result? No micro-cracks forming under thermal cycling—a major cause of premature failure.

Don’t overlook the small things. One foreman in Abu Dhabi told us: “If your clamp doesn’t hold steady, even the best blade will chatter. We now check for lateral play before each shift—and it saves hours of rework.”

These aren’t theoretical concepts—they’re proven strategies from real jobsites. Whether you're slicing granite in Saudi Arabia or polishing concrete in Qatar, understanding these principles means fewer headaches, longer tool life, and happier crews.

Want to dive deeper into how smart blade design boosts productivity and reduces downtime? Explore our technical deep-dive series →