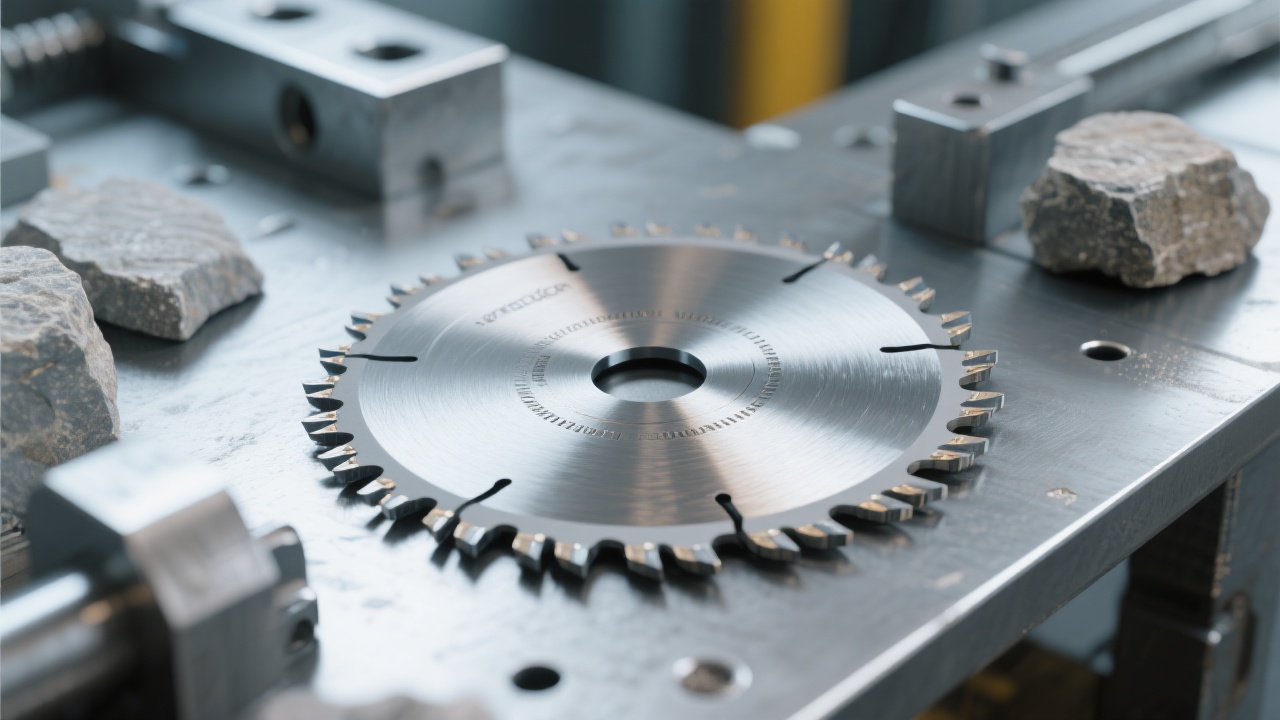

In the industrial cutting field, especially within construction and stone processing sectors, controlling cutting noise and vibration has become increasingly important for operational efficiency and worker comfort. Through 18 years of hands-on global experience, it is evident that many professionals underestimate how tooth design impacts these challenges. This tutorial explores how Henan Youde Superhard Tools Co., Ltd.’s 400H brazed diamond saw blade leverages advanced tooth design optimization to significantly lower noise and vibration during cutting, while maintaining exceptional durability and precision.

Cutting noise and vibration mainly stem from abrupt contact impacts between abrasive particles and the workpiece. Poorly optimized tooth geometry and inconsistent segment brazing exacerbate these effects, causing uneven stress distribution and micro-chatter during operation. For instance, in projects requiring high hardness material cutting — such as granite or reinforced concrete — vibrations often spike, not only degrading the cut surface quality but also increasing operator fatigue.

The 400H combines precise carbide brazing technology with a unique tooth profile engineered to buffer and distribute cutting forces evenly. Key technical highlights include:

Field testing conducted at a major Southeast Asian construction site revealed:

These results translate into less operator fatigue, improved cut quality, and longer operational life—confirming the design theory in real working conditions.

To fully leverage the low-noise and vibration benefits of the 400H saw blade, follow these four essential steps:

When placing the 400H against conventional diamond saw blades in similar price brackets, several distinct advantages emerge:

These comparisons reinforce the 400H blade’s reputation as a durable, high-performance solution—especially suited for environments requiring extended cutting cycles with minimal operator fatigue.

In sum, the 400H brazed diamond saw blade exemplifies the principle that durability is the real hard truth. By optimizing tooth design, it not only extends blade life but also reduces noise and vibration, creating a safer and more pleasant operating environment. For procurement specialists and technical managers, this translates into reduced total ownership costs and enhanced workforce productivity.

Ready to experience the cutting-edge benefits of optimized saw blade technology? Explore Practical Solutions Tailored for Your Industry and see real results from partner installations worldwide.

Have you encountered similar noise and vibration challenges in your projects? Share your specific scenarios in the comments or contact us directly—we can provide customized case studies and expert recommendations to optimize your cutting operations.