In the highly competitive global industrial manufacturing market, the choice of a suitable cutting saw blade is a critical decision for enterprises aiming to enhance their competitiveness. The ZS400H brazed diamond saw blade has emerged as a revolutionary solution, offering a perfect blend of high performance, durability, and environmental friendliness.

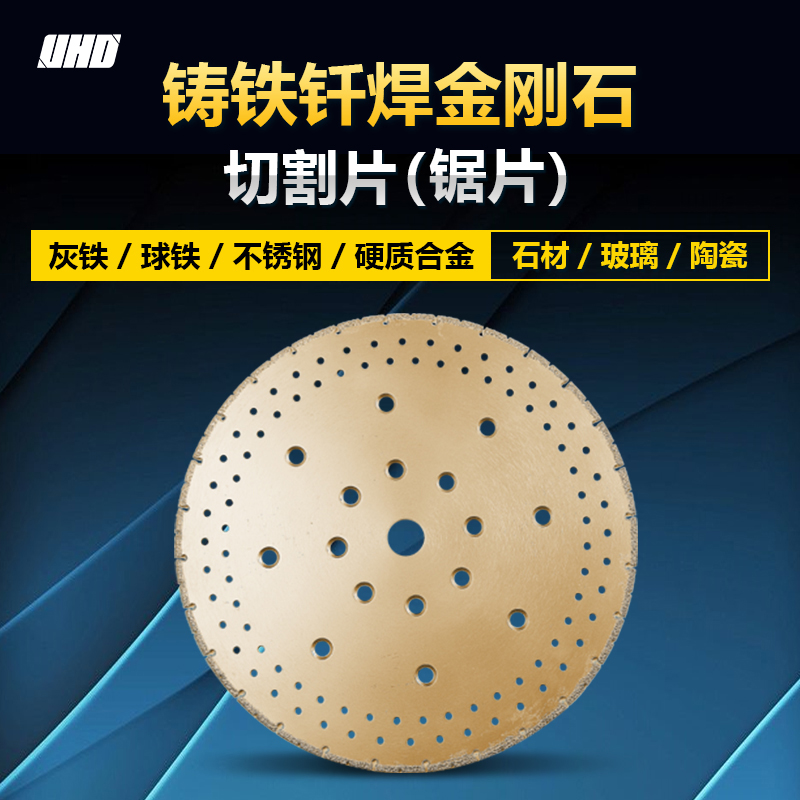

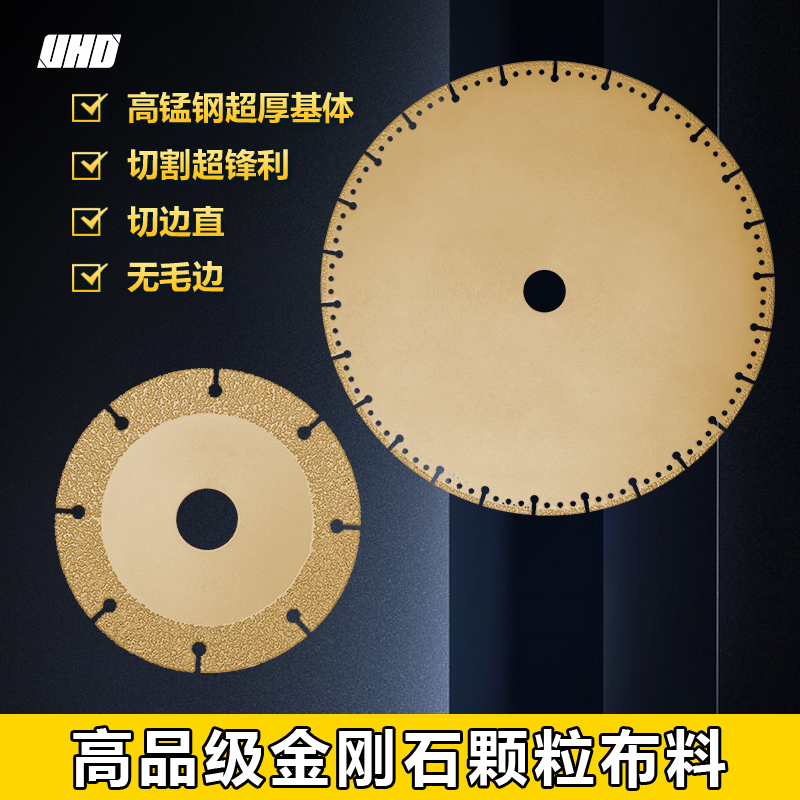

The ZS400H is meticulously designed with advanced diamond particles and an ultra - thick high - manganese steel substrate. The advanced diamond particles, sourced from top - grade materials, provide exceptional hardness and cutting ability. This enables the saw blade to effortlessly cut through complex workpieces such as gray cast iron, ductile cast iron, and cemented carbide. The ultra - thick high - manganese steel substrate, on the other hand, offers superior strength and stability, ensuring that the saw blade can withstand the rigors of high - intensity cutting operations.

The ZS400H's outstanding wear resistance and sharpness significantly extend its service life. On average, it can last up to 30% longer than traditional saw blades in similar applications. This means fewer blade replacements, which directly translates into lower replacement costs. Moreover, reduced downtime for blade changes also leads to increased productivity, further reducing overall operating costs. A leading automotive parts manufacturing company reported a 25% reduction in their annual cutting tool costs after switching to the ZS400H saw blade.

The smooth cutting process of the ZS400H ensures high - speed and accurate cutting. Its unique tooth design and advanced diamond coating allow for a cutting speed that is 20% faster than conventional saw blades. This not only shortens the production cycle but also improves the quality of the cut surface, reducing the need for secondary processing. In a case study of a machinery manufacturing plant, the implementation of the ZS400H saw blade led to a 15% increase in their daily production output.

In today's era of increasing environmental awareness, the ZS400H stands out with its low - dust cutting feature. Traditional cutting methods often generate a large amount of dust, which not only poses a threat to the health of workers but also pollutes the working environment. The ZS400H, however, reduces dust emissions by up to 40% during the cutting process. This creates a cleaner and safer working environment, helping enterprises meet strict environmental regulations.

Many global manufacturing enterprises have already experienced the benefits of the ZS400H saw blade. A European metal processing company commented, "The ZS400H has completely transformed our cutting operations. Its long service life and low - dust cutting performance have not only saved us costs but also improved the working environment for our employees." Another Asian machinery manufacturer stated, "Since using the ZS400H, our production efficiency has increased significantly, and the quality of our products has also been enhanced."

The ZS400H brazed diamond saw blade offers a comprehensive solution for manufacturing enterprises seeking to balance productivity and environmental responsibility. Its advanced design, multiple advantages, and proven performance in real - world applications make it an ideal choice for cutting a wide range of materials. By choosing the ZS400H, enterprises can achieve a win - win situation of improving production efficiency and reducing environmental impact.