In the cutting tool industry, especially within stone and metal processing sectors, procurement managers and technical specialists often wrestle with balancing cutting quality, operational efficiency, and environmental concerns. Traditional cutting discs frequently present challenges such as rough edges, excessive dust emissions, and accelerated wear, directly impacting product quality and increasing operational costs. After years of collaboration with manufacturers and end-users in diverse industrial landscapes, it has become evident that optimizing the tooth geometry of cutting discs plays a pivotal role in overcoming these obstacles.

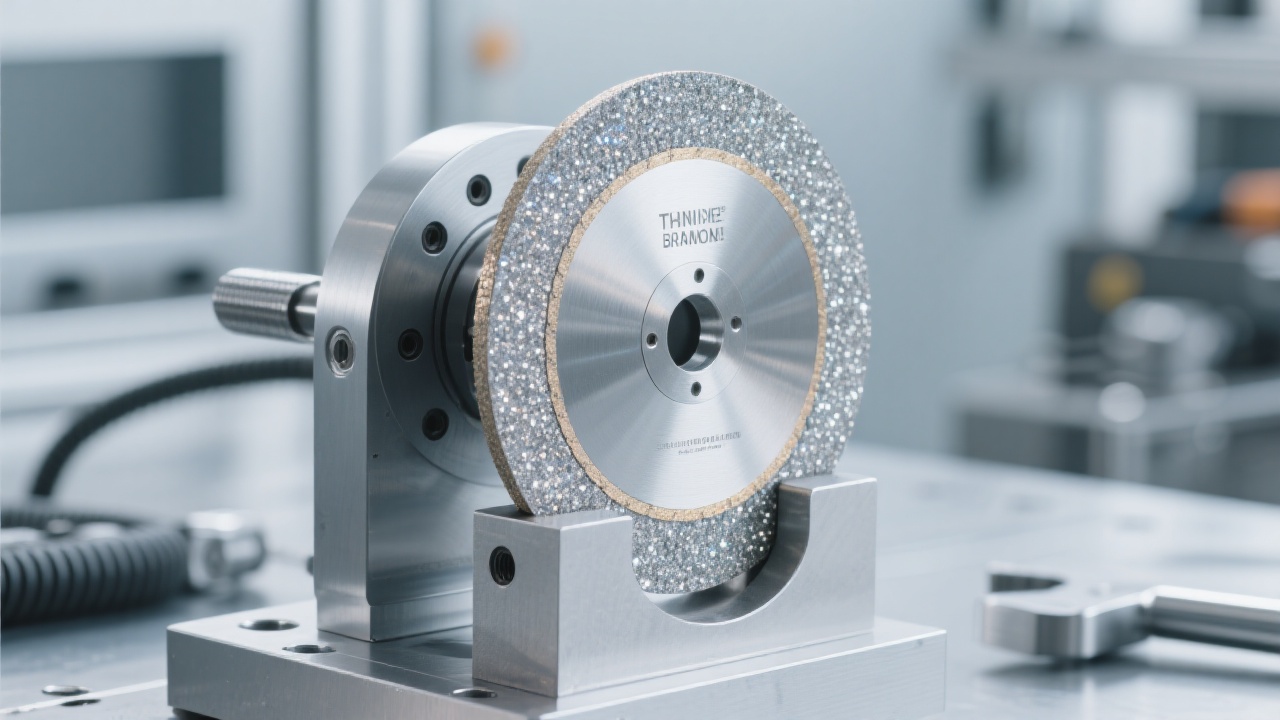

The UHD series 400 welding diamond cutting discs, developed by Henan Youde Superhard Tools Co., Ltd., introduces a meticulously engineered tooth geometry aimed at elevating cutting performance. By integrating ultra-sharp abrasive grains with a robust high-manganese steel substrate, UHD discs optimize the mechanics of engagement between disc and workpiece.

The design principle focuses on precise angling and spacing of the cutting teeth to ensure minimal resistance during engagement, promoting smooth cuts and reducing mechanical stress on the disc. This results in a significant decrease in cutting burrs and edge chipping, which are common issues in conventional discs with blunt or inconsistent teeth.

| Feature | Traditional Cutting Disc | UHD 400 Cutting Disc |

|---|---|---|

| Cutting Edge Geometry | Standard flat or slightly beveled teeth | Precision-angled teeth with optimized spacing |

| Cutting Quality | Often uneven with visible burrs | Smooth, burr-free edges requiring minimal post-processing |

| Dust Emission | High dust generation leading to workplace hazards | Reduced dust due to efficient cutting path and chip evacuation |

| Disc Durability | Lower wear resistance under heavy use | Enhanced lifespan from superior bonding of abrasives and steel base |

From real-world applications, UHD's tooth design has demonstrated a 20-30% reduction in cutting time and a 40% decrease in post-cut finishing effort, directly translating to enhanced productivity and cost savings.

A featured client in the metal processing sector reported frequent challenges related to edge chipping and excessive dust when working with stainless steel sheets. After switching to UHD 400 cutting discs, they observed:

These improvements contributed to a streamlined production workflow and significant operational cost reduction. The key driver was UHD's optimized tooth geometry that facilitated smoother cutting action and better chip removal.

Beyond cutting accuracy, UHD’s unique tooth design promotes a reduction in airborne particulates, which is increasingly important under tightening occupational health regulations globally. By minimizing dust, companies not only protect their workforce but also reduce the need for costly dust extraction systems.

Furthermore, the ergonomic design decreases vibration and noise during operation, providing a more comfortable environment for machine operators and reducing fatigue over long shifts.

The tooth profile defines the cutting force distribution and material removal efficiency. UHD’s design employs a sharper tooth angle similar to a serrated knife blade, allowing each tooth to precisely slice rather than crush material. This prevents energy loss and heat buildup, resulting in cleaner cuts and less disc wear.

Analogous to a well-designed saw blade used by carpenters, the right tooth geometry ensures that chips are efficiently cleared from the kerf, avoiding clogging that would otherwise reduce cutting speed and increase friction.

This principle was evident when UHD technical teams assisted a stone processing plant in Southeast Asia struggling with high dust and slow throughput. Adjustments to tooth spacing and sharpening drastically improved cutting smoothness and reduced particulate emissions by roughly 45%, confirmed via onsite particle monitoring.

Enterprises seeking to upgrade their cutting tools should evaluate their core production demands—whether prioritizing speed, edge quality, or environmental compliance. UHD’s 400 series welding diamond cutting discs offer a versatile balance suitable for metal and stone industries alike.

By choosing discs with optimized tooth geometry and high-performance materials, companies gain:

In comparison, traditional cutting discs mainly feature uniform, flat tooth profiles that are easier to manufacture but compromise on cut smoothness and longevity. UHD’s focus on engineering tooth shape and abrasive integration gives it an edge, especially in demanding environments.

It’s clear that tooth geometry is not merely a design detail but a critical factor influencing cutting disc performance. UHD brand’s innovation exemplifies how targeted optimization can provide measurable advantages:

Ready to transform your cutting operations? Contact us today to experience the exceptional performance of UHD cutting discs.