Brazing technology remains the backbone of manufacturing high-performance diamond saw blades, particularly for 400mm diameter models employed across stone processing and construction industries. This article offers an in-depth technical exploration of how precise control over brazing parameters, coupled with optimized blade design and material selection, directly influences saw blade stability — markedly reducing operational noise and vibration while elevating cutting efficiency and operator comfort.

The pattern and density of diamond segments welded onto the blade significantly impact vibration damping and noise generation. A strategic layout—factoring in segment spacing at approximately 10–15 mm and alternating segment angles between 30° to 45°—can reduce harmonic resonance during cuts. Experimental vibration spectrum analyses showed a 15–22% drop in peak frequencies when optimized layouts were implemented.

Such modifications reduce impact stress fluctuations, enhancing cut smoothness and extending blade lifespan. Real-world case studies from construction sites confirmed these results, reporting a noticeable decrease in operator fatigue due to lower hand-arm vibration transmission.

The base metal’s material characteristics strongly govern the blade’s mechanical resonance. High-strength steel alloys with a balanced modulus of elasticity in the range of 210–230 GPa provide the necessary rigidity to prevent deformation while incorporating micro-alloying elements enhances damping properties.

Trials demonstrated that incorporating a controlled level of carbon content (0.25–0.35%) and adding trace amounts of vanadium improved the fatigue resistance, lowering crack initiation during cyclic loading. In-situ monitoring at stone processing plants under typical rotational speeds (2800–3200 RPM) recorded up to a 18% reduction in vibration amplitude compared to conventional base metals.

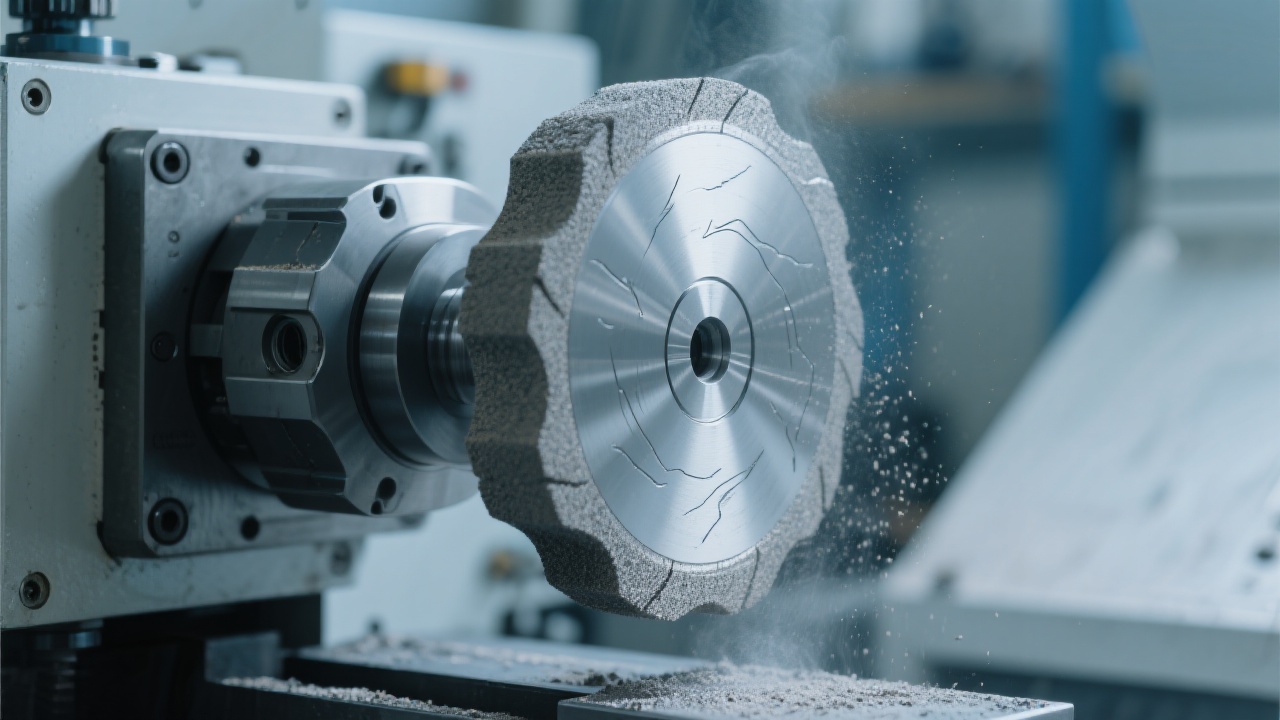

The brazing procedure is pivotal for segment adhesion and long-term blade stability. Managing thermal cycles prevents microcracks and residual stresses that impair performance. Optimal brazing involves a gradual heating ramp—approximately 10°C/min—holding at a peak temperature near the silver solder melting point (~750°C) for 3–5 minutes, followed by a controlled cooldown phase.

Such thermal profiles ensure homogeneous solder flow and alloy interdiffusion without compromising the steel substrate’s grain structure. Thermal imaging during lab trials confirmed uniform temperature distribution with variance limited to ±5°C across the blade surface, correlating with diminished post-brazing distortion.

Beyond design and materials, field performance hinges on tuning rotational velocity (RPM) and feed rate synergy. Laboratory and site-verified data advise maintaining rotational speeds within 2800–3200 RPM while adjusting feed speeds between 2.5–4.0 meters/min to balance cutting aggressiveness and vibration mitigation.

Empirical data collected over 15 months from multiple construction sites demonstrated that adhering to these parameters reduces peak vibration amplitudes by up to 25% and cuts noise levels below 85 dB(A), improving compliance with occupational health standards.

Frontline feedback from operators indicates that early-stage vibration anomalies often manifest as distinctive tonal shifts or irregular high-frequency buzzing. Equipped with handheld accelerometers, operators can perform quick spectral scans to detect abnormal peaks beyond baseline thresholds of 15 m/s² RMS acceleration.

| Detection Method | Indicative Values | Suggested Action |

|---|---|---|

| Handheld Vibration Meter | > 15 m/s² RMS | Realign blade fixture, inspect for segment wear |

| Auditory Anomaly Detection | Unusual buzzing or rattling | Verify clamping torque and fixture stability |

| Visual Inspection | Segment cracks, base plate deformation | Replace blade or perform maintenance brazing |

Additionally, adjusting clamp torque within the range of 25–30 Nm during blade mounting proved effective in maintaining alignment accuracy, reducing lateral oscillation by approximately 20%. These practical insights empower field technicians to sustain blade stability and prolong operational windows.

Implementing these validated brazing process controls and design optimizations enables industry professionals to achieve unparalleled saw blade stability, noise reduction, and cutting precision in diverse operational environments.