In the global cutting industry, businesses are constantly grappling with two significant challenges: cost - efficiency and environmental protection. The High - Performance Welded Diamond Cutting Disc 400 emerges as a revolutionary solution that addresses these pain points head - on, making it an ideal choice for professional users around the world.

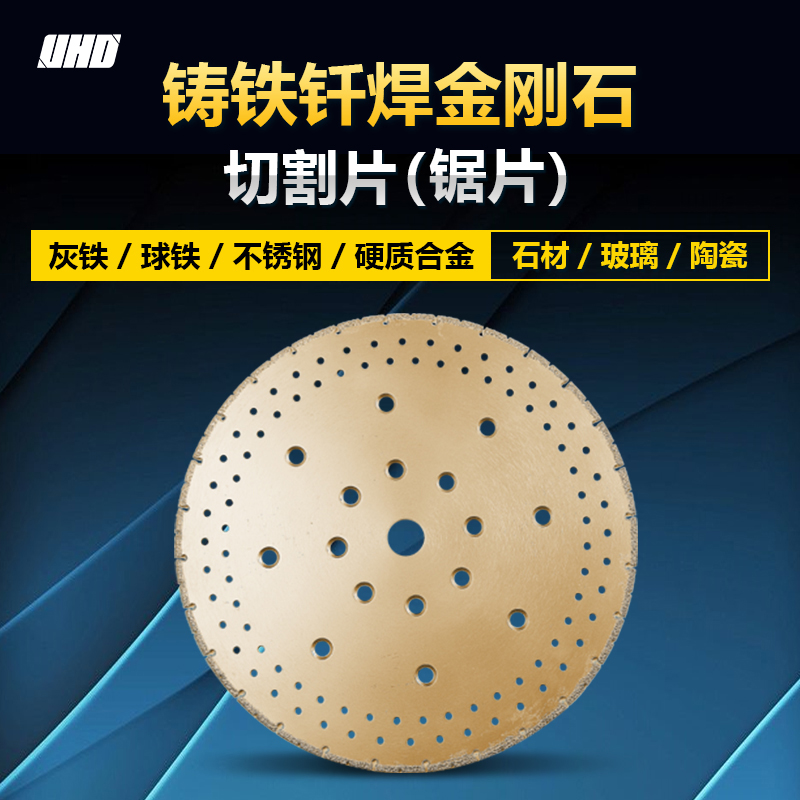

The High - Performance Welded Diamond Cutting Disc 400 combines ultra - sharp diamond abrasives with a robust substrate. This unique combination results in outstanding stability and cutting performance. Traditional resin blades typically last for about 50 - 100 cutting operations before they need to be replaced. In contrast, our diamond cutting disc can endure up to 500 cutting operations, which is a five - to ten - fold increase in lifespan. This dramatic improvement in durability significantly reduces the frequency of disc replacements, thereby lowering the overall operating costs for businesses.

Environmental concerns are at the forefront of modern industrial operations. Our cutting disc is designed with precision in mind. The specially engineered tooth profile and edges ensure a smooth, burr - free cutting experience. This not only enhances the quality of the cut but also has a positive environmental impact. Traditional cutting methods can generate up to 20 grams of dust per cutting operation. With our diamond cutting disc, the dust generation is reduced by up to 70%, dropping to only 6 grams per operation. This reduction in dust not only creates a cleaner working environment but also contributes to a more sustainable cutting process.

One of the key advantages of the High - Performance Welded Diamond Cutting Disc 400 is its versatility. It is suitable for a wide range of applications, including metal processing and stone processing. In metal processing, it can cut through various types of metals, such as steel, aluminum, and copper, with ease. In stone processing, it can handle granite, marble, and other hard stones efficiently. This versatility means that businesses no longer need to invest in multiple types of cutting discs for different materials, further reducing costs.

The use of our cutting disc can also lead to significant improvements in productivity. Traditional cutting methods may require multiple passes to achieve a clean cut, which is time - consuming and labor - intensive. Our diamond cutting disc can complete the cutting in a single pass in most cases. This reduces the labor intensity for workers and allows them to complete more cutting tasks in less time. On average, businesses can expect a 30% increase in productivity when using our cutting disc.

In conclusion, the High - Performance Welded Diamond Cutting Disc 400 is a game - changer in the cutting industry. It offers a perfect balance between cost - efficiency, environmental friendliness, and high - performance. It is truly a new choice for the sustainable development of the cutting industry.

Don't miss out on this opportunity to revolutionize your cutting operations. Take the first step towards a more sustainable and cost - effective future by trying our High - Performance Welded Diamond Cutting Disc 400. Contact us today to learn more about this innovative product and how it can benefit your business.