In the metal cutting industry, businesses are constantly seeking ways to enhance production efficiency and reduce operational costs. The choice of a high-performance diamond cutting blade is crucial in achieving these goals. This article focuses on the UHD brand welded diamond cutting blade 400 from Henan Youde Superhard Tools Co., Ltd., exploring its quality, performance, and advantages over traditional blades.

Metal cutting operations often face challenges such as low efficiency, poor cutting quality, and high costs. Traditional cutting blades may wear out quickly, resulting in frequent blade replacements and increased downtime. For example, a metal processing factory used to spend approximately 30% of its production time on blade changes with traditional blades. This not only affected the overall production schedule but also increased labor costs.

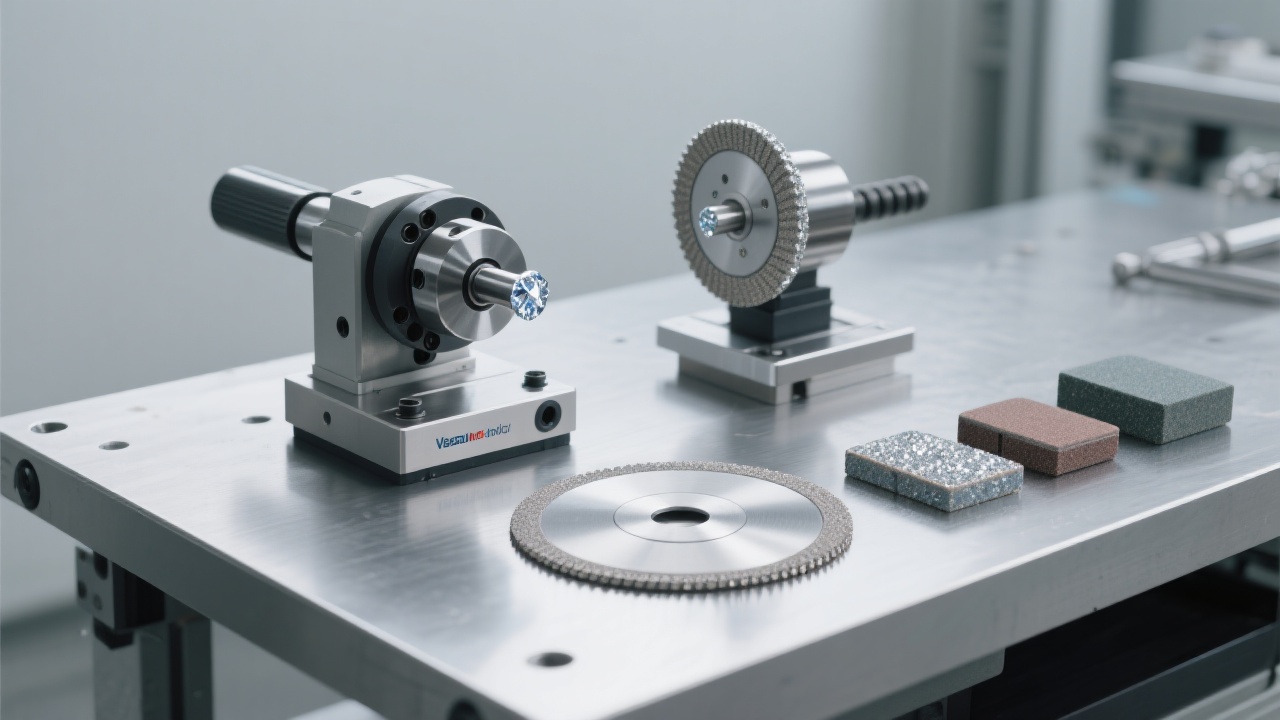

The UHD welded diamond cutting blade 400 strictly adheres to the ISO 9001 quality management system. This ensures that every blade meets high - quality standards. The diamond abrasive used in the blade is of high quality, which provides excellent cutting performance. The combination of the super - sharp diamond abrasive and a strong high - manganese steel base makes the blade extremely durable.

Compared with traditional blades, the UHD blade 400 offers superior cutting performance. In a comparative test, the UHD blade 400 was able to cut through a 10 - mm thick steel plate in just 30 seconds, while a traditional blade took about 60 seconds. Moreover, the UHD blade 400 can maintain its sharpness for a longer time. It has been found that the UHD blade 400 can cut approximately 500 meters of metal before significant wear, while a traditional blade can only cut about 100 meters.

The longer lifespan of the UHD blade 400 directly translates into cost savings. Although the initial investment in the UHD blade 400 may be slightly higher than that of traditional blades, in the long run, it can reduce the total cost. For instance, a company that switched to the UHD blade 400 reduced its annual blade - related costs by about 25%.

The UHD blade 400 features a unique tooth shape and a precision - cut edge design. This design allows for smooth, burr - free cutting. When cutting metal pipes, the UHD blade 400 leaves a clean and smooth edge, eliminating the need for additional finishing processes. Additionally, the design helps create a low - dust cutting environment, which is not only beneficial for the health of workers but also meets environmental protection requirements.

The UHD welded diamond cutting blade 400 is not only suitable for metal processing but also has applications in the stone processing industry. In metal processing, it can be used for cutting various metals such as steel, aluminum, and copper. In stone processing, it can cut granite, marble, and other stones with high efficiency. A stone processing workshop reported that after using the UHD blade 400, their processing efficiency increased by about 20%.

In summary, the UHD brand welded diamond cutting blade 400 is a high - performance cutting solution that offers strict quality control, excellent performance, unique design features, and diverse applications. It can significantly improve production efficiency, reduce costs, and enhance cutting quality. If you are looking for a reliable and efficient diamond cutting blade for your metal or stone cutting operations, the UHD blade 400 is an ideal choice.