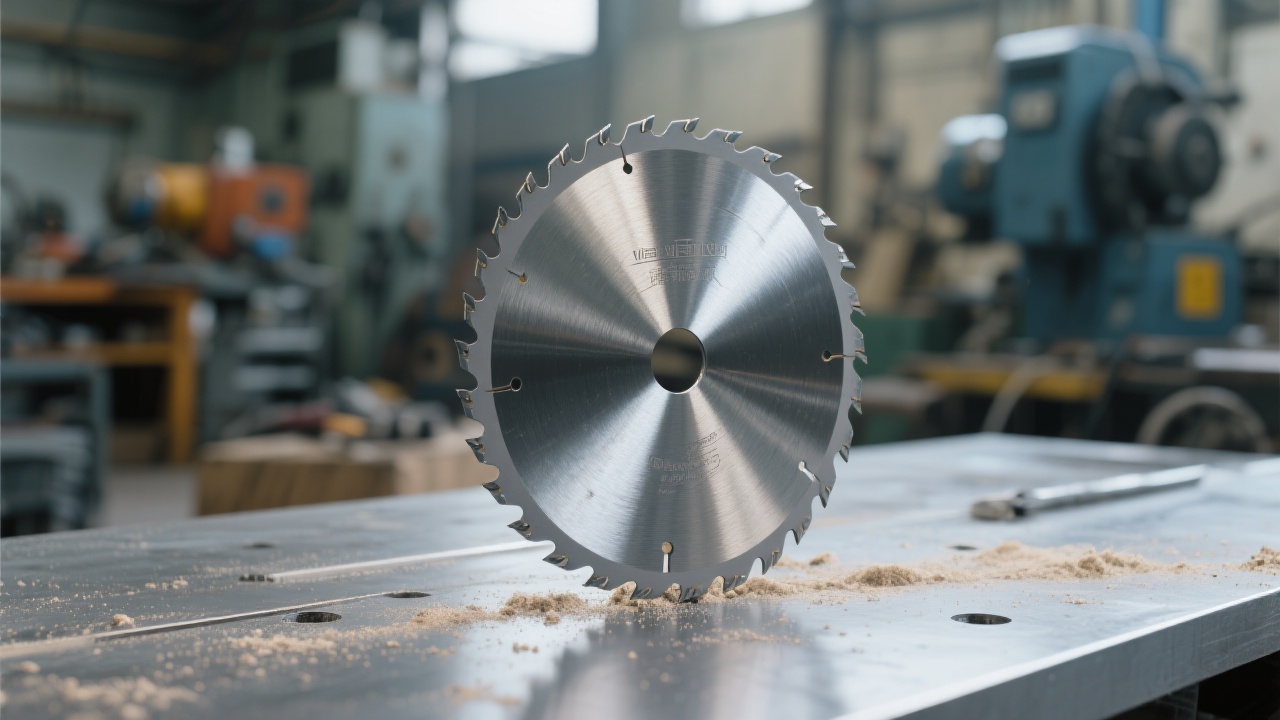

In today's fiercely competitive industrial manufacturing landscape, the quest for high-performance cutting tools is more crucial than ever. These tools not only enhance production efficiency but also play a significant role in reducing operational costs and meeting environmental standards. One such tool that stands out is the ZS400H brazed diamond saw blade. Let's delve into its core advantages.

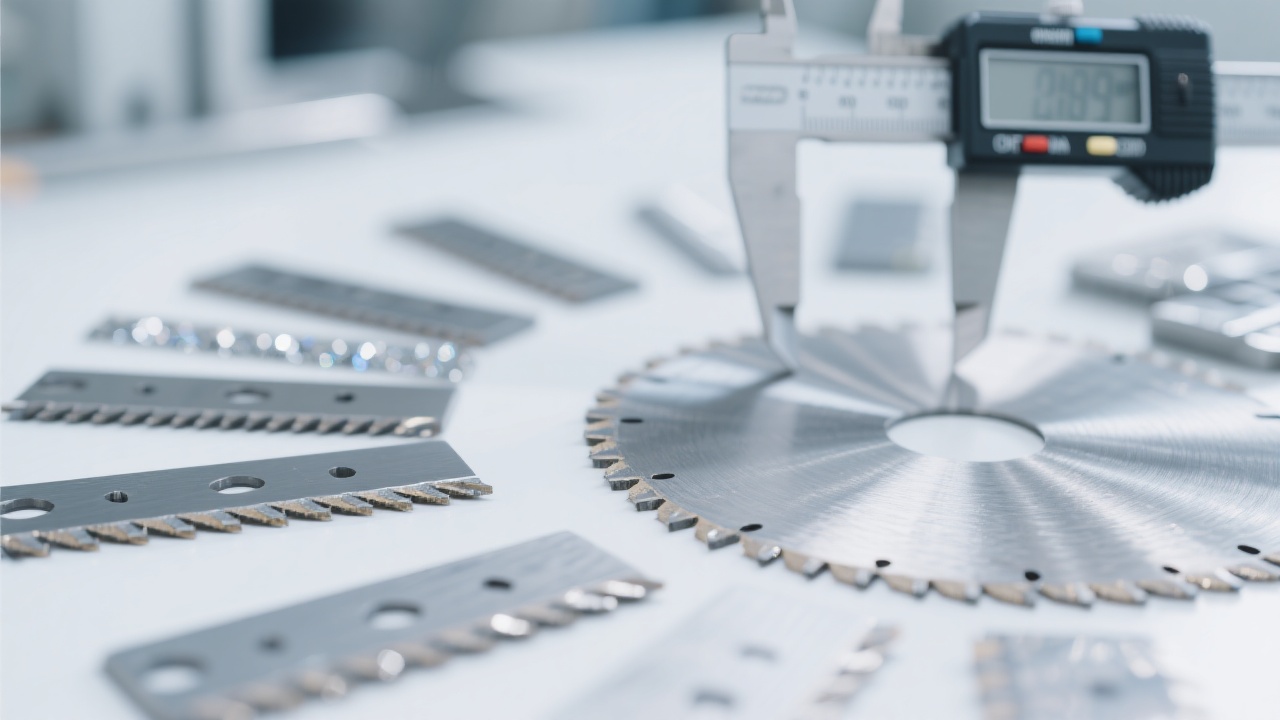

The ZS400H saw blade is equipped with high - grade diamond particles. These diamonds are carefully selected for their hardness and abrasion resistance. In comparison to conventional resin - bonded saw blades, the diamond particles on the ZS400H can withstand higher temperatures and pressures during the cutting process. For instance, in a recent test conducted in a metalworking factory, the ZS400H saw blade maintained its cutting edge even after continuous cutting for 50 hours, while a traditional resin saw blade started to show significant wear after just 10 hours.

The saw blade features an ultra - thick high - manganese steel matrix. This design provides excellent stability and strength. The high - manganese steel can absorb the shock and vibration generated during cutting, reducing the risk of blade breakage. A case in point is a construction company that used the ZS400H saw blade to cut concrete. The thick matrix allowed the blade to maintain a straight cutting path, resulting in cleaner and more precise cuts. In contrast, a thinner - matrix saw blade from another brand often deviated from the cutting line, leading to uneven cuts.

The tooth profile of the ZS400H saw blade is uniquely designed to optimize the cutting process. The teeth are arranged in a way that ensures efficient chip removal, preventing chips from clogging the blade and reducing the cutting force required. In a woodworking workshop, when using the ZS400H saw blade to cut hardwood, the unique tooth design allowed for smooth and fast cutting, with minimal effort from the operator. This is in contrast to some saw blades with a simple tooth design, which often require more force and result in slower cutting speeds.

The ZS400H saw blade offers significant cost savings in the long run. Due to its long - lasting diamond particles and strong matrix, the blade has a much longer service life compared to traditional saw blades. On average, the ZS400H saw blade can last up to 5 times longer than a conventional resin saw blade. This means fewer blade replacements, reducing the cost of purchasing new blades and the labor cost associated with blade changes. A manufacturing plant reported that after switching to the ZS400H saw blade, they were able to save approximately 30% on their annual cutting tool expenses.

With its high - performance components, the ZS400H saw blade can greatly improve production efficiency. The sharp diamond particles and unique tooth design enable faster cutting speeds. In a metal fabrication shop, the use of the ZS400H saw blade increased the cutting speed by about 40% compared to the previous saw blade. This allowed the shop to complete more orders in the same amount of time, leading to increased productivity and higher profits.

Environmental protection is an important aspect of modern industrial production. The ZS400H saw blade helps in dust control. The efficient chip removal design reduces the amount of dust generated during cutting. In a stone processing factory, after using the ZS400H saw blade, the dust concentration in the workshop was reduced by nearly 50%. This not only creates a healthier working environment for the employees but also meets the strict environmental regulations.

Many customers have provided positive feedback on the ZS400H saw blade. A customer from a machinery manufacturing company said, "The ZS400H saw blade has truly changed our cutting process. It's durable, efficient, and has significantly reduced our production costs. We no longer have to worry about frequent blade replacements." Another customer from a construction firm mentioned, "The precision and dust - control performance of the ZS400H saw blade are outstanding. It's a great addition to our toolbox."

The ZS400H brazed diamond saw blade offers a comprehensive solution for industrial cutting needs. Its technical highlights translate into significant cost savings, efficiency improvements, and better environmental performance. By choosing the ZS400H saw blade, businesses can build a competitive edge in the market and move towards a more sustainable and efficient production model. Let every cut be more worry - free and efficient with the ZS400H saw blade. Say goodbye to frequent replacements and embrace stable output.

Are you looking to upgrade your cutting tools? Click here to learn more about the ZS400H saw blade and take your industrial production to the next level!