How to Scientifically Choose Concrete Cutting Blades? Comprehensive Guide to 400mm Diameter Blades

2025/09/23

Tutorial Guide

This article provides an in-depth analysis of how to scientifically select concrete cutting blades, with a special focus on the application value of 400mm diameter brazed diamond blades in various construction scenarios. It explores key factors such as material hardness compatibility, cutting depth requirements, and operational modes including dry and wet cutting. Featuring detailed case studies from high-rise building demolition, floor treatment, and bridge maintenance, the article thoroughly explains the suitability and advantages of 400mm blades. It also highlights the technological advancements of modern brazing over traditional welding, along with practical advice on blade wear identification and cooling method selection. Supported by technical data and illustrative charts, this content aims to assist construction professionals, project managers, and procurement decision-makers in making precise blade choices to ensure optimal cutting efficiency and safety. A subtle product recommendation for Henan Youde Superhard Tools Co., Ltd.'s 400H brazed diamond blades concludes the guide, promising excellent performance for project success.

How to Scientifically Choose Concrete Cutting Blades: A Comprehensive Guide to 400mm Diameter Blades

Selecting the right concrete cutting blade is crucial for optimizing performance, safety, and cost-efficiency on construction sites. Among various blade sizes, the 400mm diameter diamond-tipped blade, especially those manufactured using advanced brazing technologies, stands out for its versatility in demanding applications. This article delves into the scientific factors influencing blade choice, practical usage scenarios, and the technological advantages brought by brazed diamond segments — all aimed at construction professionals and procurement experts looking for precise guidance in blade selection.

Core Factors in Concrete Cutting Blade Selection

Four key factors must be assessed scientifically when choosing a concrete cutting blade:

| Selection Factor |

Importance |

Typical Range / Requirement |

| Material Hardness |

High - Must match concrete aggregate's Mohs hardness |

Concrete: Mohs 6~7; Blade Segment: Synthetic diamond or high-grade tungsten carbide |

| Cutting Depth |

Moderate to Deep Cuts |

400mm blade accommodates up to ~120mm cutting depth |

| Operation Mode |

Wet vs. Dry Cutting Conditions |

Wet cutting enhances cooling, dry cutting preferred for convenience but increases wear |

| Blade Durability & Segment Bonding |

Critical for long-term usage and cost-efficiency |

Brazed diamond segments offer enhanced wear resistance compared to traditional welding |

Application Scenarios for 400mm Concrete Cutting Blades

The 400mm blade size is highly versatile and widely used in construction projects demanding precise and efficient cuts. Some flagship application areas include:

- High-Rise Building Demolition: The blade’s moderate diameter enables deep cuts in reinforced concrete walls while maintaining stable blade operation.

- Flooring & Surface Preparation: Ideal for ground surface work such as removing damaged concrete floors or creating control joints, especially where controlled depth and smooth finish are required.

- Bridge Repair & Infrastructure Maintenance: Enables precise cutting of concrete components without excessive vibration, crucial for structural safety during partial repairs.

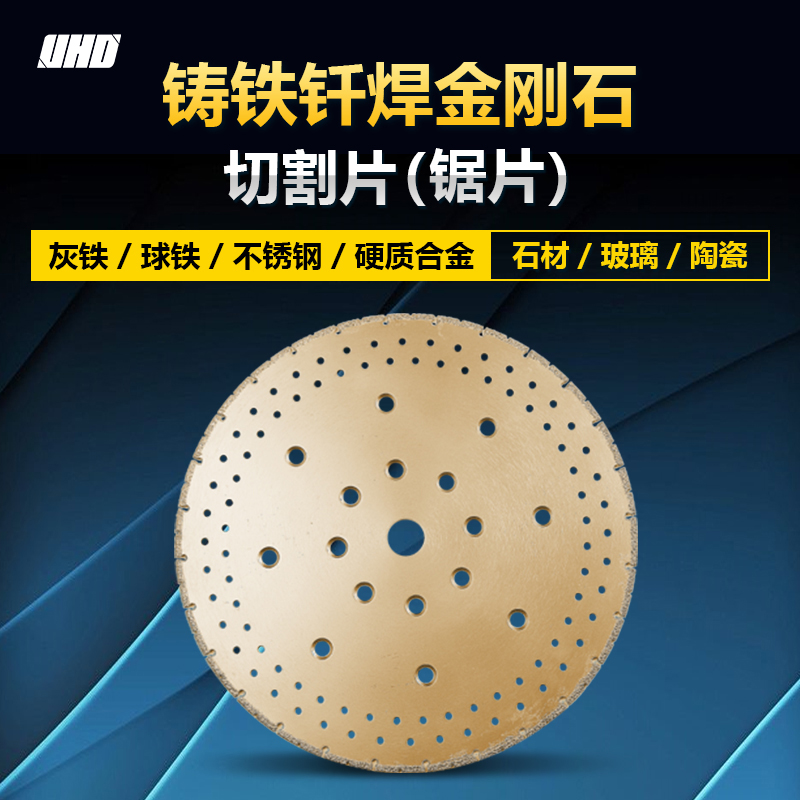

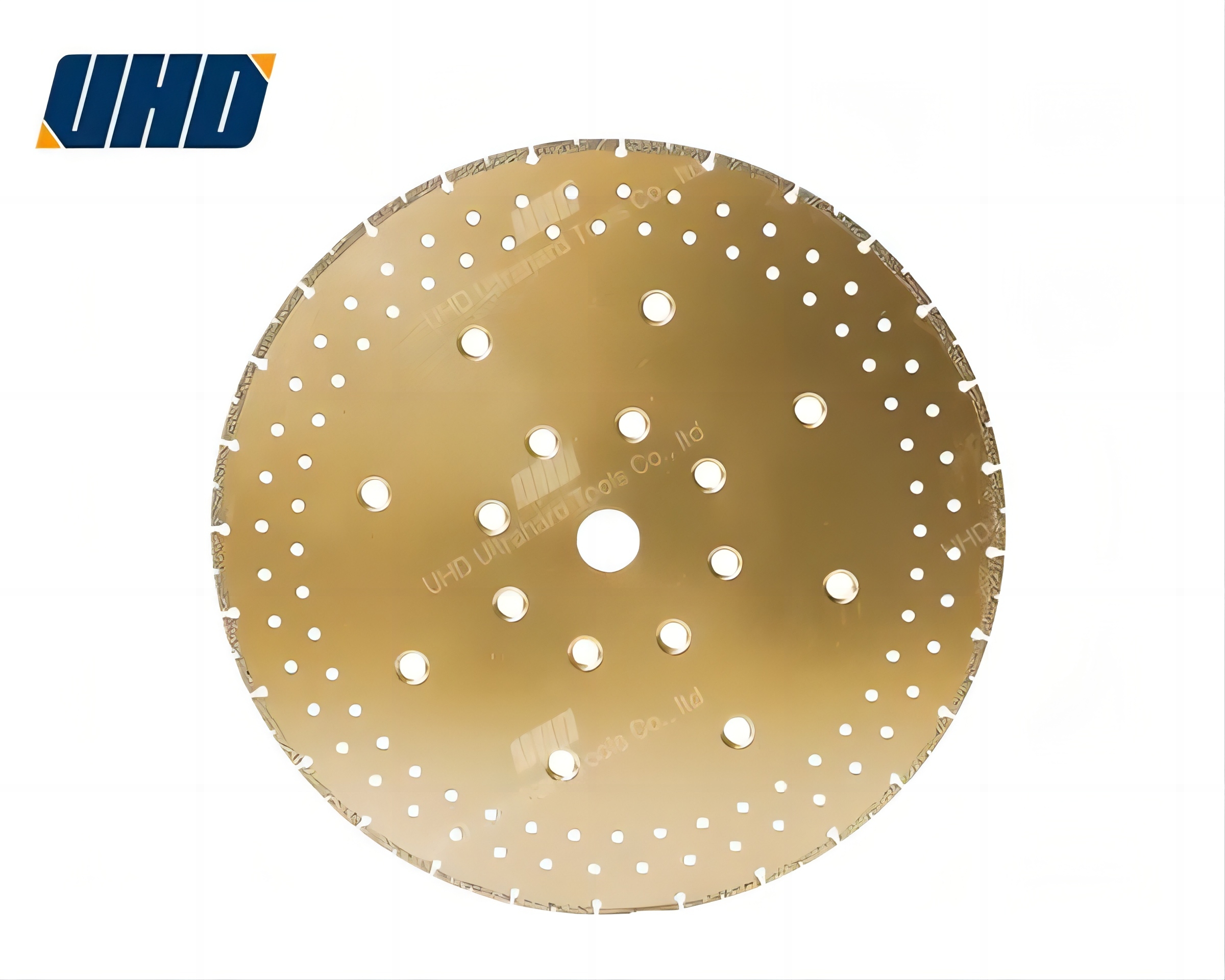

Brazed Diamond Segment Technology vs. Traditional Welding

Traditional welded diamond segments attach the diamond edge via electric welding, which often results in weaker bonding and faster segment drop-off under prolonged use. In contrast, modern brazing technology employs a copper or silver-based filler metal at high temperatures, creating a metallurgical bond between the blade core and diamond segments.

| Technology |

Bond Strength |

Wear Resistance |

Operational Efficiency |

| Traditional Welding |

Moderate; prone to segment loosening |

Lower; segments wear out faster under heavy use |

Average cutting speed; increased downtime for blade replacements |

| Brazed Diamond Segments |

High; strong metallurgical bond |

Significantly improved; 20-30% longer lifespan |

Higher cutting speed; less downtime and improved productivity |

This enhanced bonding and wear resistance translate to tangible savings on operational costs and improved project timelines.

Practical Tips: Segment Wear Recognition and Cooling Strategies

Recognizing segment wear is vital for timely blade replacement and avoiding operational hazards:

- Uneven segment height reduction or cracking indicates imminent failure.

- Reduced cutting efficiency combined with increased motor load signals segment dullness needing intervention.

Cooling methods affect blade longevity and cut quality:

- Wet Cutting: Provides superior cooling, reduces dust, and lowers blade temperatures, effectively extending blade life by up to 25%. Recommended for most concrete applications but requires water management on-site.

- Dry Cutting: Offers convenience by eliminating cooling water needs but causes higher cutting temperatures and faster blade wear. Use dry blades with optimized segment design and intermittent cutting to mitigate heat.

Case Studies Highlighting 400mm Blade Advantages

High-Rise Building Demolition: Using 400mm brazed blades enabled clean and efficient wall openings for heavy equipment passage. The blade’s hardness withstood reinforced concrete, reducing blade changes by 30% compared to standard welding blades.

Industrial Ground Floor Prep: Efficient cutting of concrete flooring with wet 400mm blades minimized dust by 80% and accelerated surface removal by 1.5x compared to older blades.

Bridge Repair: Precision cuts with brazed 400mm blades helped isolate damaged sections without compromising adjacent structures, enhancing project safety and control.

FAQ: Common Questions on Selecting and Using 400mm Concrete Cutting Blades

-

Q1: Is a 400mm blade suitable for cutting heavily reinforced concrete?

-

Yes, especially when using brazed diamond segments designed for high hardness materials. These blades maintain sharpness longer and penetrate steel reinforcement effectively.

-

Q2: Can I use a 400mm blade for both wet and dry cutting?

-

Many 400mm blades are engineered for wet cutting to optimize performance and lifespan, but some specialized dry-cutting blades are available. Always verify manufacturer specifications and site conditions.

-

Q3: How do I know when to replace the blade?

-

Replace the blade when segments are worn close to the core (usually less than 5mm thickness), or if cutting speed declines despite proper operation, to avoid risks and inefficiency.