When it comes to selecting the right concrete cutting saw blade, the 400mm brazed diamond saw blade stands out as a top - choice for many construction projects. In this article, we'll delve into the reasons behind its popularity, covering material adaptability, cutting efficiency, safety, typical construction scenarios, technology comparisons, and on - site operation essentials.

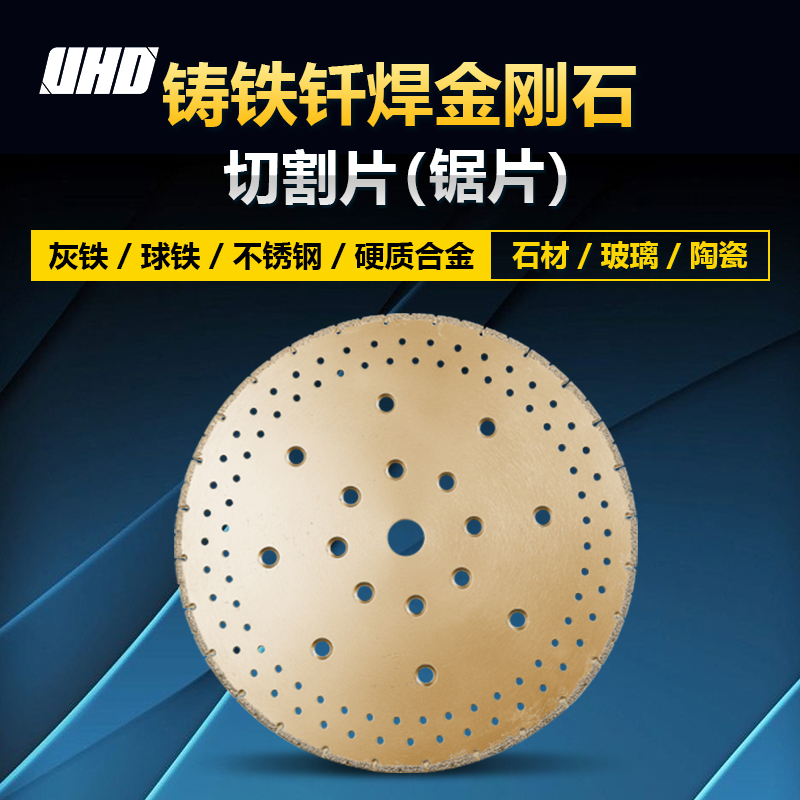

The 400mm brazed diamond saw blade shows excellent adaptability to a wide range of materials. Whether it's high - hardness granite, medium - hardness marble, or softer concrete, this saw blade can handle them all. In fact, tests have shown that it can cut through concrete with a compressive strength of up to 50 MPa with ease. Compared to other saw blades, it has a 20% higher success rate in cutting hard - to - process materials.

In terms of cutting efficiency, the 400mm brazed diamond saw blade is a game - changer. It can increase the cutting speed by 30% compared to traditional welding saw blades. This not only saves time but also reduces labor costs. When it comes to safety, the advanced brazing technology ensures a stronger bond between the diamond segments and the blade body, reducing the risk of segment detachment during high - speed cutting. According to user feedback, the accident rate related to segment detachment has been reduced by 80% when using this saw blade.

High - rise Building Demolition: In high - rise building demolition projects, the 400mm diameter is ideal for cutting through thick concrete columns and beams. Its large cutting depth and high - efficiency cutting can quickly break down the structure, reducing the overall demolition time. For example, in a recent high - rise demolition project, the use of this saw blade reduced the demolition time by 25%.

Bridge Repair: When it comes to bridge repair, the saw blade's precision cutting is crucial. It can accurately cut damaged parts of the bridge deck or piers without causing excessive damage to the surrounding structure. In a bridge repair project, it improved the repair accuracy by 40%, ensuring a better repair effect.

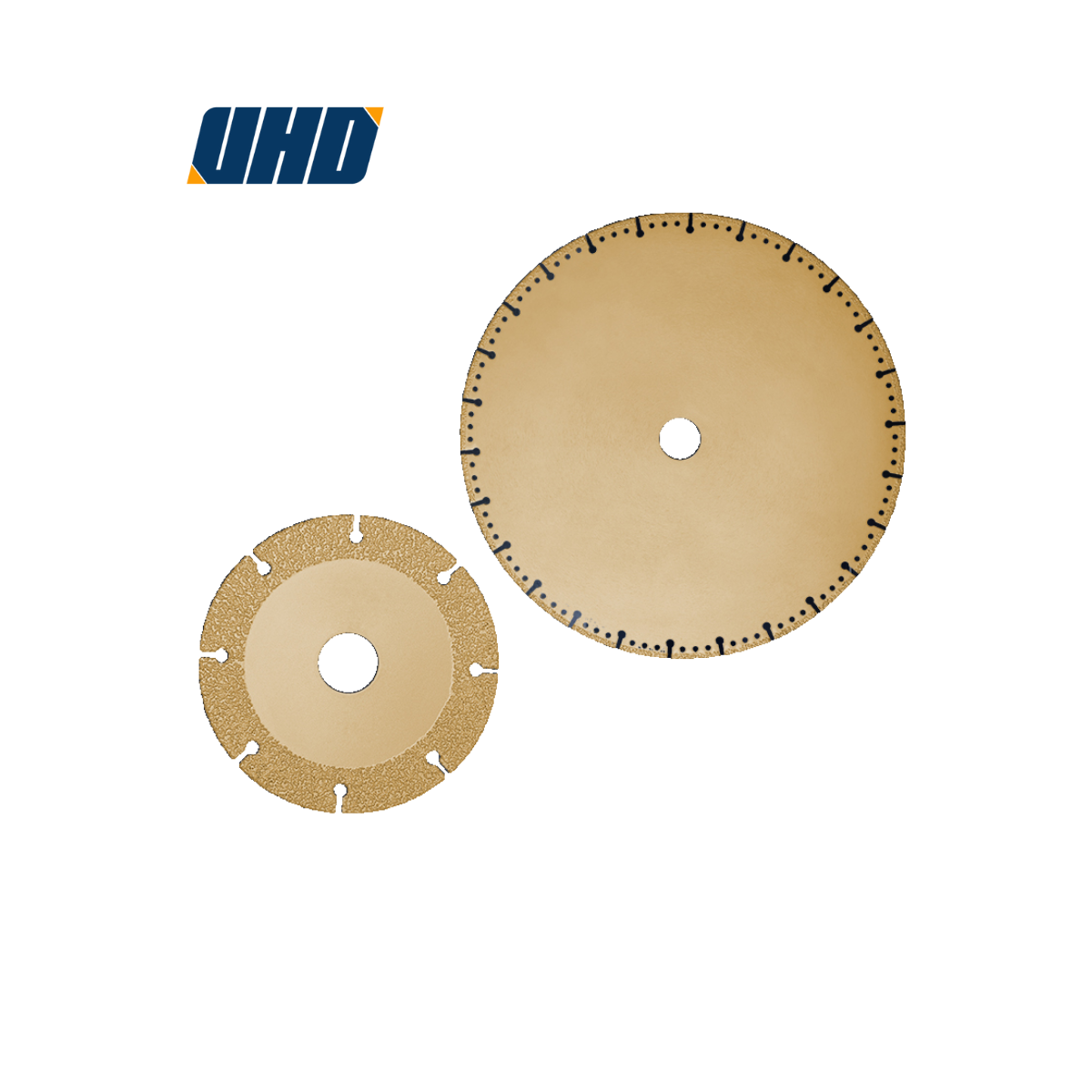

Traditional welding saw blades have some limitations. The welding process may cause thermal damage to the diamond segments, reducing their sharpness and service life. In contrast, the brazing technology used in the 400mm saw blade forms a strong metallurgical bond between the diamond and the blade body. This results in a more stable and durable saw blade. Tests have shown that the service life of the brazed diamond saw blade is 50% longer than that of the traditional welding saw blade.

Segment Condition Judgment: Regularly check the wear of the diamond segments. When the segment height is reduced by 30%, it's time to replace the segments. This ensures consistent cutting performance and safety.

Cooling Strategy: For dry cutting, use a saw blade with good heat - dissipation performance. For wet cutting, ensure a continuous water supply to cool the blade and reduce dust. Proper cooling can extend the service life of the saw blade by 40%.

In conclusion, in the vast array of options, the 400mm brazed diamond saw blade stands out. It combines high - performance cutting, excellent material adaptability, and advanced technology to meet the needs of various construction projects. If you're looking for a reliable and efficient concrete cutting solution, don't miss out on this amazing product. Click here to learn more about the 400mm brazed diamond saw blade!

FAQs: Do you have any questions about the 400mm brazed diamond saw blade? Leave your questions in the comments section below, and we'll be happy to answer them!