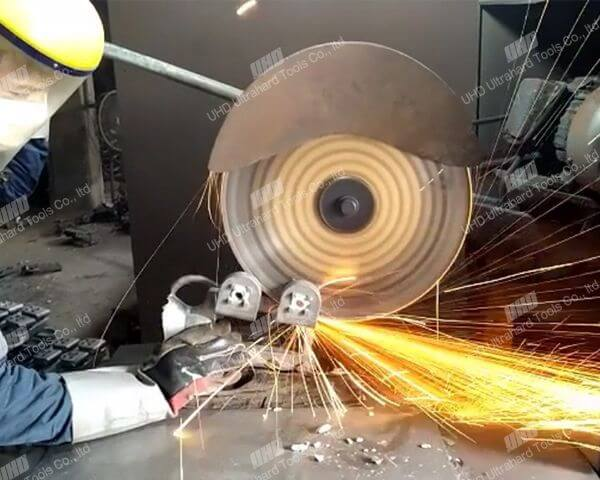

In modern industrial manufacturing, the efficiency of metal cutting tools directly impacts production speed, cost control, and product quality. As industries strive for higher precision and productivity, the adoption of advanced cutting solutions has become essential. Among these, UHD ultra-hard material tools have emerged as a game-changer, offering unmatched performance in high-precision machining, durability, and customization.

UHD ultra-hard material tools are developed through rigorous research and collaboration with leading academic institutions. These tools are engineered using advanced diamond and cubic boron nitride (CBN) technologies, ensuring superior hardness and thermal stability. According to internal data, UHD tools can maintain sharpness up to 3 times longer than conventional cutting tools, significantly reducing tool replacement frequency and downtime.

One of the key advantages of UHD tools is their ability to achieve extremely tight tolerances and surface finishes. In precision metal cutting applications, such as aerospace and semiconductor manufacturing, the accuracy of cuts is critical. UHD tools are capable of maintaining dimensional consistency within ±0.005 mm, meeting the highest international standards. This level of precision reduces rework and waste, improving overall production efficiency.

Traditional cutting tools often require frequent maintenance and replacement due to wear and tear. UHD tools, however, are designed for extended service life. Industry reports indicate that companies using UHD tools experience a 40% reduction in machine downtime and a 30% decrease in maintenance costs. This not only improves operational efficiency but also enhances return on investment (ROI).

A global automotive manufacturer implemented UHD cutting tools in its production line for high-strength steel components. Before the upgrade, the company faced frequent tool breakages and long downtimes. After switching to UHD tools, the production cycle time was reduced by 25%, and tool life increased by 2.5 times. The company reported a 15% improvement in overall equipment effectiveness (OEE), demonstrating the tangible benefits of UHD technology.

| Metric | Before UHD | After UHD |

|---|---|---|

| Tool Life (hours) | 80 | 200 |

| Downtime (hours/month) | 15 | 9 |

| Production Cycle Time (minutes/unit) | 12 | 9 |

Choosing UHD ultra-hard material tools means investing in a solution that delivers:

As global manufacturers continue to seek ways to optimize production processes, UHD ultra-hard material tools provide a reliable and high-performance solution. With proven results in real-world applications, these tools are setting new benchmarks in industrial cutting. For businesses looking to enhance productivity and reduce costs, UHD offers a compelling choice backed by innovation and quality.

Ready to elevate your production efficiency? Discover how UHD cutting tools can transform your operations today.

Explore UHD Solutions Now