In today’s competitive global manufacturing landscape, the demand for high-precision, durable industrial cutting tools has never been greater. UHD Superhard Materials Tools Co., Ltd. has distinguished itself by forging a strategic partnership with Henan University of Technology and other leading academic institutions to pioneer innovative diamond cutting solutions. This collaboration has enabled UHD to achieve products that rigorously comply with international quality standards, delivering unmatched performance and reliability to customers worldwide.

The cornerstone of UHD’s success lies in the integration of academic research with applied industrial technology. By working closely with top engineering faculties at Henan University of Technology, UHD continuously refines the microstructure of their industrial diamond cutting tools, optimizing both hardness and toughness. These tools undergo multiple phases of in-house and third-party testing—including ISO 9001:2015 quality system certification and adherence to ANSI standards—to guarantee optimal cutting precision and long service life.

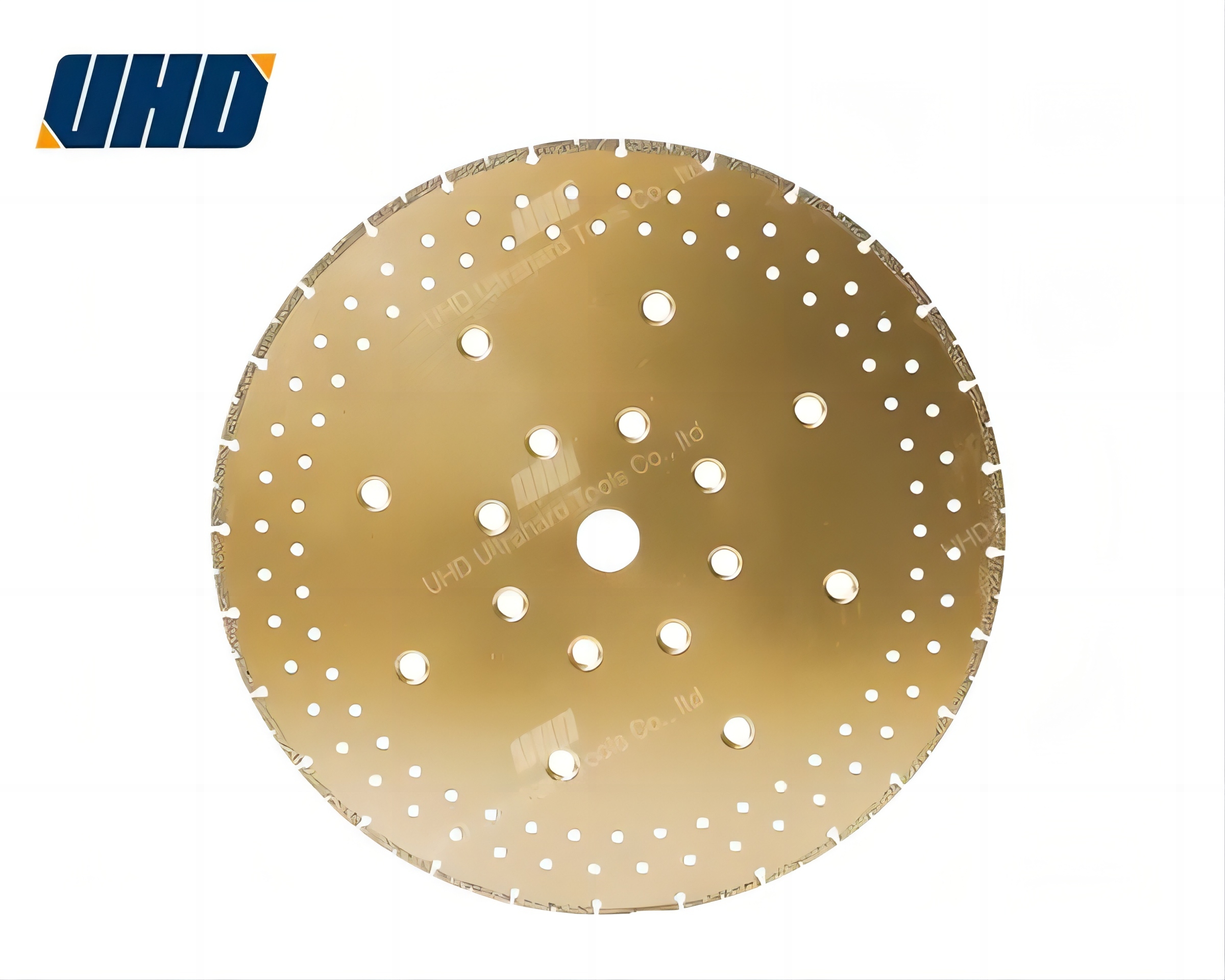

State-of-the-art Computer-Aided Design (CAD) models simulate cutting conditions, resulting in tool geometries that significantly reduce metal fatigue while maintaining extreme sharpness. Laboratory fatigue testing reveals that UHD’s diamond saw blades maintain over 85% efficiency after 5000 operational hours—outperforming competitors by up to 30%.

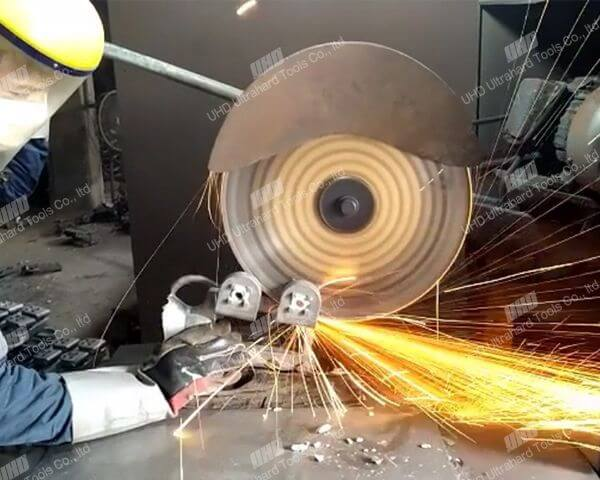

UHD offers a comprehensive portfolio of diamond cutting tools, including segmented blades, continuous rim discs, and turbo blades to meet varied industrial applications—from aerospace alloy fabrication to large-scale steel pipeline cutting. The company’s custom engineering team collaborates directly with clients to develop tailored tool configurations that match specific materials and cutting conditions, further enhancing precision and durability.

| Tool Type | Typical Application | Durability (Operational Hours) |

|---|---|---|

| Segmented Diamond Blade | Concrete & Masonry Cutting | 4500+ |

| Continuous Rim Disc | Ceramic Tile & Glass Cutting | 4000+ |

| Turbo Blade | Metallic and Alloy Cutting | 5000+ |

A leading automotive parts manufacturer reported a 20% increase in cutting throughput and a 35% reduction in tool replacement frequency after adopting UHD’s custom-designed diamond saw blades. This translated into a plant-wide 15% decrease in unscheduled downtime and a direct cost saving of approximately $300,000 annually.

Similarly, a global aerospace components supplier credited UHD’s tools with helping achieve ISO 14001 certified sustainable production objectives by reducing abrasive waste by 25%, enhancing both operational efficiency and environmental compliance.

UHD’s corporate philosophy centers on continuous innovation, customer-focused customization, and sustainable industrial partnerships. By combining academic insights with production expertise, UHD remains at the forefront of superhard material tooling technology. Their rigorous quality management assures every diamond cutting tool not only meets but exceeds global industry standards—empowering customers to maintain competitive advantages in ever-evolving markets.

“Since switching to UHD’s diamond cutting tools, we’ve consistently observed longer tool life and significant reductions in maintenance downtime—key factors that improved our overall production KPIs.” – Global Manufacturing Client

Trust UHD Superhard Materials Tools Co., Ltd. to deliver international quality diamond cutting tools designed in close cooperation with top universities. Upgrade to UHD’s solutions and experience reduced downtime, enhanced cutting precision, and cost-effective maintenance for your operations worldwide.

Contact UHD for Customized Industrial Cutting Solutions