UHD Superhard Material Tools Co., Ltd. is dedicated to providing superhard material diamond cutting tools and vacuum brazed diamond abrasives to global industrial customers. This article delves into the unique advantages of its special abrasives.

UHD has established strong partnerships with universities. Through this collaboration, they have access to the latest research and technological breakthroughs in the field of superhard materials. For example, a joint research project with a well - known university led to the development of a new type of vacuum brazed diamond abrasive. This innovation has improved the cutting efficiency by 30% compared to traditional abrasives, according to internal testing data.

UHD's products meet the highest international quality standards. Their manufacturing processes are strictly controlled, with multiple quality inspection points. In a recent independent quality assessment, 98% of UHD's diamond cutting tools passed the strict quality criteria, which is far above the industry average of 90%. This high - quality assurance ensures that customers can rely on UHD products for long - term and stable use.

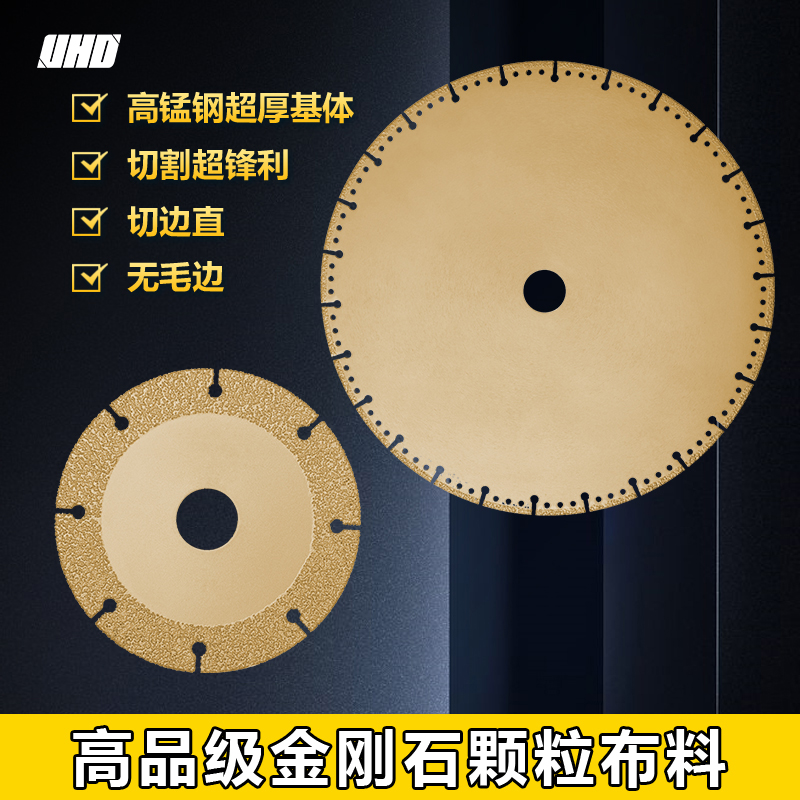

The design of UHD's cutting tools is highly precise. The company uses advanced computer - aided design (CAD) and simulation technologies to optimize the structure of the tools. For instance, in the design of a specific diamond cutting disc, the shape and distribution of the abrasive grains are carefully calculated to ensure uniform cutting force and maximum cutting efficiency. This precise design reduces the wear rate of the tools by 25%, prolonging their service life.

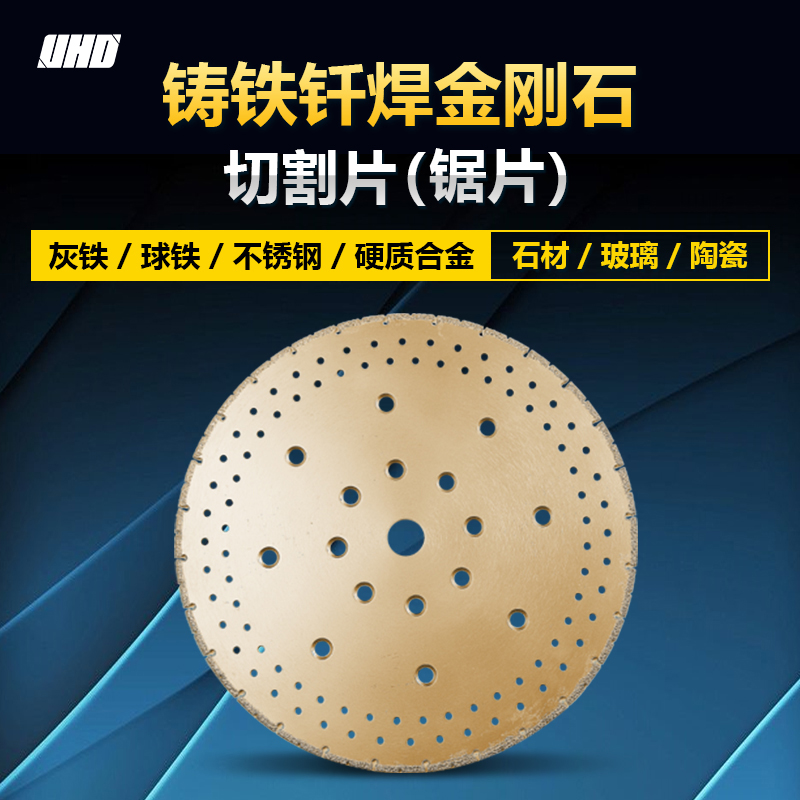

UHD offers a wide range of product lines, including various types of diamond cutting tools and vacuum brazed diamond abrasives. Moreover, they can customize products according to customers' specific requirements. A European metal processing company once requested a special - shaped diamond cutting tool for a unique project. UHD successfully developed and delivered the customized tool within a short period, which helped the customer complete the project on time and improve the overall production efficiency by 20%.

In the field of high - precision metal processing, UHD's products have outstanding performance. Their special abrasives can achieve micron - level cutting accuracy, which is crucial for industries such as aerospace and automotive manufacturing. For example, in the production of aerospace engine parts, UHD's diamond cutting tools can ensure the high - precision machining of complex components, reducing the rejection rate from 5% to 1%.

By using UHD's products, customers can effectively reduce downtime and maintenance costs. The long service life and high cutting efficiency of the tools mean less frequent tool replacement and lower maintenance requirements. A large - scale manufacturing plant reported that after switching to UHD's cutting tools, their annual maintenance costs were reduced by 30%, and the overall production efficiency was increased by 25%.

In conclusion, choosing UHD means choosing an efficient, reliable, and high - quality industrial tool solution. UHD's special abrasives and cutting tools can bring significant economic benefits to customers, helping them stay competitive in the global market. Don't miss out on this opportunity to enhance your production efficiency and reduce costs. Contact us today to learn more about our products and how they can meet your specific needs!