In today’s global industrial manufacturing market, where competition intensifies by the day, the choice of cutting tools directly impacts an enterprise's operational efficiency and cost-effectiveness. As manufacturers strive to deliver precision, durability, and productivity, selecting the right cutting saw blade becomes a strategic decision rather than a mere procurement task.

UHD Ultra Hard Materials Tools Co., Ltd. addresses this core challenge through its flagship product: the ZS400H Tungsten Carbide Brazed Diamond Saw Blade. Engineered specifically for the complexities of modern industrial cutting needs, this saw blade exemplifies how intelligent tool design enhances a company’s competitive edge.

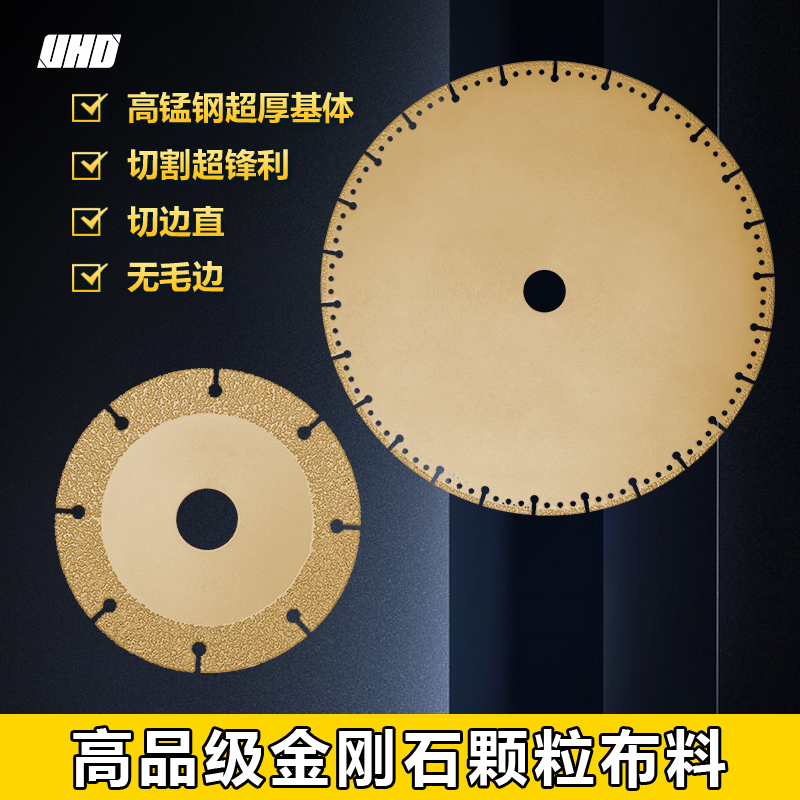

The ZS400H is meticulously crafted to handle a wide range of challenging workpieces, including hardened metals and composite materials. Its core innovation lies in the integration of premium-grade diamond particles that ensure superior abrasion resistance and maintain outstanding sharpness throughout the cutting cycle—qualities that traditional resin-bonded blades often fail to sustain.

Complementing the diamond abrasive is a high-manganese steel extra-thick base. This robust base secures stability and safety during high-speed cutting operations, reducing vibration and providing consistently smooth cuts. Moreover, the reinforced blade structure enables consistent precision without compromising structural integrity.

One of the most compelling benefits of the ZS400H lies in its remarkable durability. Tests have shown that the blade lifespan extends over 300% longer than conventional resin saw blades, drastically reducing the frequency of replacements. This longevity translates into significant savings in maintenance, downtime, and overall operational expenses.

Industrial facilities employing the ZS400H report a surge in cutting efficiency by approximately 25%, attributed to its ultra-hard diamond surface and reinforced base design. The blade’s smooth cutting action also reduces labor intensity, ensuring safer working conditions while enhancing productivity.

Furthermore, the ZS400H complies with environmental standards through minimal dust generation during cutting, promoting a cleaner workspace and aligning with modern eco-conscious manufacturing goals.

MetalTech Solutions Ltd., a leading engineering firm specializing in aerospace components, integrated the ZS400H blades into their production line six months ago. They reported a 28% reduction in blade-related downtime and a 22% decrease in material waste due to superior cut quality. According to their operations manager, “The stability and precision offered by ZS400H blades have essentially redefined our production efficiency standards.”

Similarly, Global Fabricators Inc., serving automotive manufacturing, experienced enhanced throughput rates and saw a measurable drop in labor fatigue. Their switch to the ZS400H blade also supported sustainability initiatives by significantly lowering airborne particulate emissions.

Beyond technical superiority, the ZS400H saw blade offers enterprises a strategic advantage by marrying performance with sustainability. Its enhanced cutting sharpness, extended lifespan, and sturdiness reduce total cost of ownership—a critical metric influencing procurement decisions globally.

By adopting advanced saw technology from UHD Ultra Hard Materials Tools Co., Ltd., companies strengthen their operational backbone, enabling rapid adaptation to market demands while fostering eco-friendly manufacturing practices.