In the highly competitive landscape of metal fabrication, the precision and efficiency of industrial cutting tools directly impact production throughput, quality, and cost-effectiveness. Cutting tools optimized for specific metal types and processing conditions can increase machining accuracy by up to 30%, while simultaneously reducing tool wear and downtime. UHD Ultra-Hard Materials Tools Co., Ltd. leverages leading-edge research collaborations with premier universities to develop diamond cutting tools that set new standards in precision, durability, and customizability. These advancements empower manufacturers worldwide to refine their metalworking processes, achieving sustainable growth and cost savings.

UHD’s diamond tools harness ultra-hard polycrystalline diamond (PCD) composites with controlled grain sizes and proprietary bonding techniques, delivering unprecedented tool life and cutting stability. Independent laboratory testing reveals UHD tools outperform conventional carbide cutting tools by 40% in wear resistance and maintain dimensional accuracy over 25% longer production cycles. Rigorous quality management systems aligned with ISO 9001 standards ensure batch-to-batch consistency that global manufacturers rely upon. Through data-driven quality analytics, UHD enables predictive maintenance frameworks, significantly lowering unexpected failures.

| Performance Metric | UHD Diamond Tools | Standard Carbide Tools |

|---|---|---|

| Wear Resistance | 1200 hours | 850 hours |

| Dimensional Accuracy Retention | 98% | 72% |

| Mean Time Between Failures (MTBF) | 2000 hours | 1400 hours |

UHD's cutting tools exhibit a range of design innovations tailored for varied industrial applications—from aerospace-grade titanium alloys to highly abrasive stainless steel components. The integration of customized geometries, coating materials, and edge treatments optimizes each tool's performance characteristics such as thermal conductivity and chip evacuation efficiency. For example, their patented multi-faceted diamond tips improve cutting speed by up to 15% while maintaining surface finish quality at Ra 0.4 μm, critical for high-precision industries like automotive and electronics.

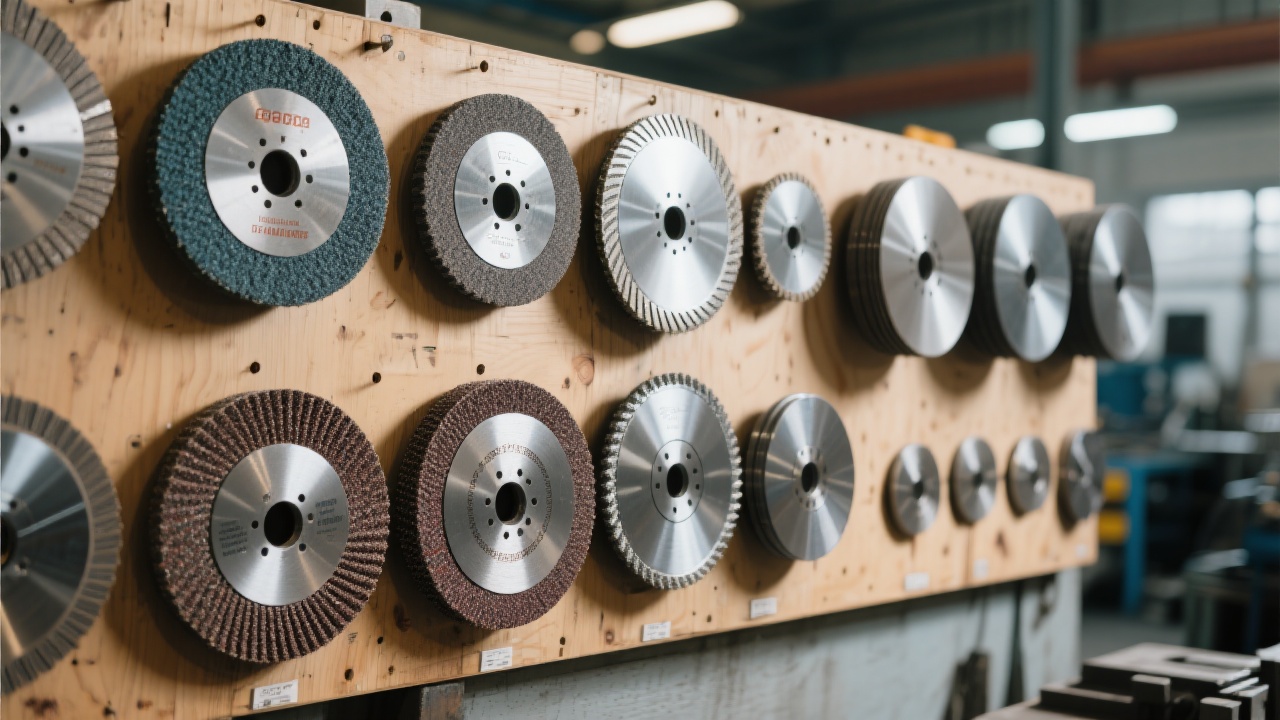

UHD offers an extensive portfolio exceeding 150 standard and bespoke cutting tool models, including saw blades, drill bits, and milling cutters. Their flexible manufacturing processes support custom tool design tailored to unique customer specifications such as feed rate optimization, workpiece hardness, and machine compatibility. Utilizing AI-guided design software coupled with real-time customer feedback, UHD delivers turnaround times for customized orders 30% faster than industry averages. This agility helps clients achieve leaner inventory management and enhance response times in fast-evolving production environments.

One leading European automotive supplier integrated UHD diamond cutting tools in their high-volume engine block machining lines. Within six months, tool replacement frequency dropped by 35%, and production cycle times reduced by 12%. These improvements translated into a 20% reduction in total process costs and an annual savings exceeding €500,000. Another case with a Chinese electronics manufacturer showed a 28% increase in precision yield resulting from UHD’s customized micro-cutting tools designed for ultra-thin copper foils.

Selecting UHD Ultra-Hard Materials Tools translates into tangible efficiency gains, extended tool life, and operational cost containment—key factors in competitive metalworking industries. Their certified quality processes, continuous innovation, and customer-centric customization deliver reliable solutions aligned with global industrial demands. For enterprises seeking to elevate their manufacturing capabilities while minimizing maintenance interruptions, UHD’s diamond cutting tools represent a strategic investment with rapid ROI.