In the demanding world of stone fabrication and construction, operators often face a silent but persistent problem: excessive vibration during cutting with diamond saw blades. This isn’t just an annoyance—it impacts tool life, worker safety, and final product quality.

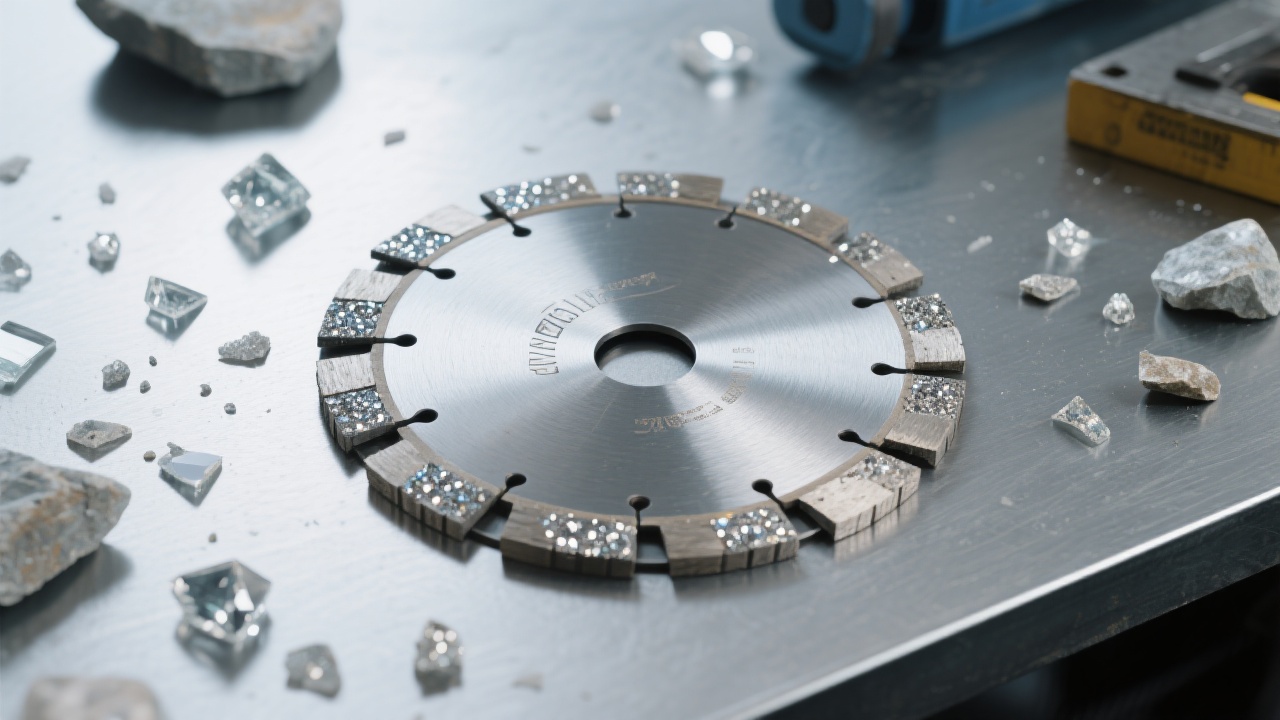

Take the 400H brazed diamond blade, for example. Used widely in granite, marble, and engineered stone applications, it's designed not only for high cutting speed but also for exceptional stability. But even the best tools need proper setup—and that’s where real-world experience matters.

What makes the 400H so effective? It starts with three key design elements:

| Component | Impact on Vibration & Noise |

|---|---|

| Diamond Segment Layout | Optimized spacing reduces harmonic resonance—up to 30% less noise vs. standard layouts (based on lab tests at 4000 RPM). |

| High-Strength Steel Base | Matches thermal expansion properties of diamond segments, minimizing micro-movement under heat stress. |

| Precision Brazing Process | Ensures uniform bond strength across all segments—critical for consistent performance over 50+ hours of continuous use. |

These aren’t just technical specs—they translate directly into cleaner cuts, fewer tool replacements, and safer working conditions. One contractor in Dubai reported a 22% drop in machine downtime after switching to this blade type, attributing the gain to better vibration control.

“If you feel your hands shaking more than usual—even slightly—you’re probably dealing with misalignment or poor clamping,” says Ahmed, a veteran stonemason from Riyadh who’s used over 50 different blade models.

Here are two simple checks every operator should do before starting a job:

These tips might seem basic—but they prevent costly mistakes. In one case study from a quarry in Turkey, improper clamping led to premature blade failure within 8 hours. After implementing these adjustments, the same team ran 40+ hours without issues.

When engineers and field workers collaborate like this, results speak louder than any marketing claim. That’s why we encourage you to dive deeper into how materials, design, and human insight combine to make modern cutting safer, faster, and quieter.

If you're serious about improving your operation’s efficiency and reducing maintenance costs, understanding these principles is step one.