In today’s fiercely competitive industrial manufacturing landscape, optimizing every segment of production is crucial to sustaining a competitive edge. One often overlooked but vital component is the cutting tool, particularly the choice of saw blades. UHD Superhard Materials Co., Ltd.’s ZS400H tungsten carbide-tipped diamond saw blade is engineered to meet the escalating needs for precision, durability, and eco-conscious operations in complex cutting applications.

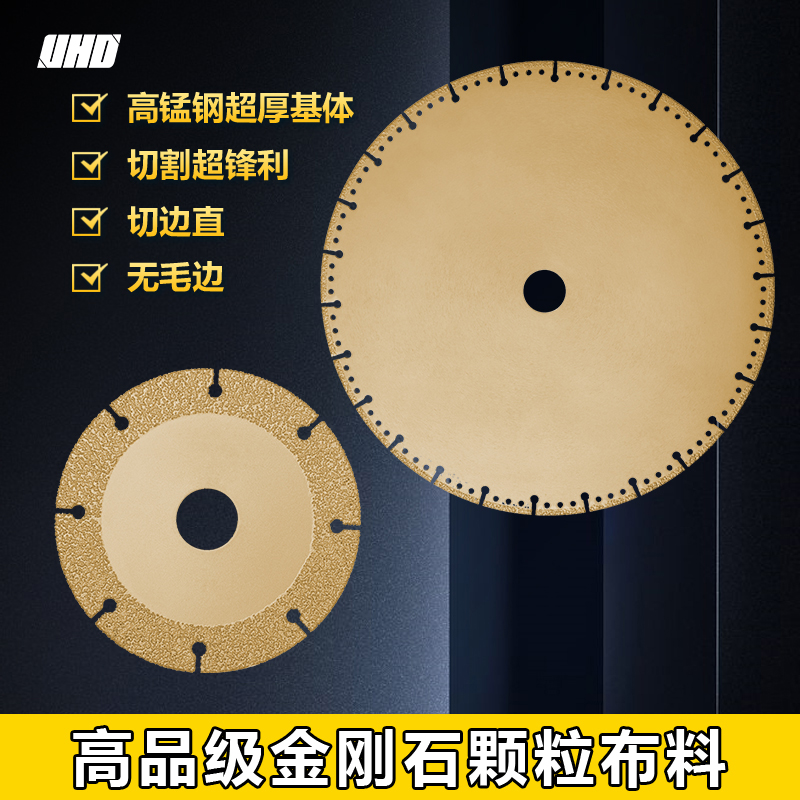

The ZS400H blade’s advanced design incorporates premium-grade synthetic diamond particles embedded within a tungsten carbide-tipped brazed segment. This combination significantly enhances abrasion resistance and cutting sharpness. Coupled with a high-manganese steel thickened base plate, it ensures stability and safety in high-speed operations. Such innovations make the ZS400H ideal for cutting a variety of challenging industrial materials including hardened metals, composites, and complex geometric components.

Unlike conventional resin-bound diamond blades, which typically show accelerated wear and frequent replacement cycles, the ZS400H blade exhibits a remarkable 30% longer effective lifespan in rigorous industrial cutting conditions. This translates into substantial reductions in downtime and maintenance costs. Moreover, its optimized tooth geometry and brazed segments minimize cutting resistance, thereby increasing cutting speed by nearly 25% without compromising precision.

Operational cost savings extend beyond blade longevity; the lower frequency of blade changes also cuts labor and material handling overhead, directly impacting the bottom line positively. The ZS400H’s sturdier structure diminishes vibration and blade deflection, delivering smoother cuts and superior surface finish quality, which is critical for downstream processing stages.

| Performance Metric | ZS400H Blade | Traditional Resin Blade |

|---|---|---|

| Blade Lifespan | Up to 1200 hours cutting time | Around 900 hours cutting time |

| Cutting Speed | 25% faster cuts | Standard cutting speed |

| Dust Emission | Reduced by 40% | Higher particulate output |

| Material Waste | Minimal blade kerf loss | Higher kerf loss |

Sustainability is no longer an option but a necessity in manufacturing. The ZS400H saw blade supports green manufacturing initiatives by significantly lowering dust emissions during cutting—up to 40% reduction compared to traditional resin blades. Heavy metal and toxic resin residues are minimized thanks to the brazed diamond segment and high-manganese base plate’s cleaner wear behavior.

Moreover, the reduced maintenance and replacement frequency decrease the environmental footprint associated with blade production, packaging, and transportation logistics. These aspects position the ZS400H blade as a sustainable solution aligning with global environmental compliance requirements and corporate social responsibility goals.

Leading manufacturers across automotive, aerospace, and heavy machinery sectors have reported enhanced production throughput and cost efficiencies since integrating the ZS400H blade. For example, a mid-sized aerospace component manufacturer decreased blade changeovers by 40% and improved cutting precision benchmarks by 15%, directly enhancing product quality and on-time delivery rates.

These results stem from the blade’s unique balance of strength, sharpness, and dimensional stability under extreme cutting conditions, validating it as an indispensable cutting solution in high-stakes industrial environments.

The ZS400H tungsten carbide-tipped diamond saw blade not only delivers superior cutting performance and longevity but also aligns with modern manufacturing demands for sustainability and cost efficiency. Its robust construction and eco-friendly operation empower manufacturers to minimize costs and maximize productivity, gaining clear competitive advantages in a demanding market.

As industrial enterprises continue to pursue technological upgrades and resource optimization, adopting advanced tools like the ZS400H blade will be instrumental in shaping resilient, future-ready manufacturing workflows.