When it comes to using 400mm concrete saw blades, the choice between dry cutting and wet cutting is crucial. Dry cutting relies on air cooling, which is suitable for scenarios where water is scarce or not allowed, such as some indoor demolition projects. However, the heat generated during dry cutting can significantly reduce the saw blade's lifespan. On the other hand, wet cutting uses water as a coolant. It can effectively reduce heat, extend the saw blade's life, and is more suitable for large - scale outdoor projects like bridge repairs. The following table shows a detailed comparison:

| Comparison Items | Dry Cutting | Wet Cutting |

|---|---|---|

| Cooling Mechanism | Air cooling | Water cooling |

| Applicable Working Conditions | Indoor projects with water - free requirements, small - scale cutting | Large - scale outdoor projects, high - precision cutting |

| Impact on Saw Blade Life | Shortens the lifespan due to high heat | Extends the lifespan by reducing heat |

The 400mm diameter saw blade is a popular choice in the construction industry. In high - rise building demolition, its large diameter allows for efficient cutting of thick concrete walls. For floor treatment, it can quickly and accurately cut through the old floor surface. In bridge repair, it can handle the precise cutting required for structural reinforcement. However, different scenarios may require different cooling methods. For example, in high - rise building demolition, dry cutting may be more convenient in some cases, while wet cutting is often preferred in bridge repair to ensure cutting quality and saw blade life.

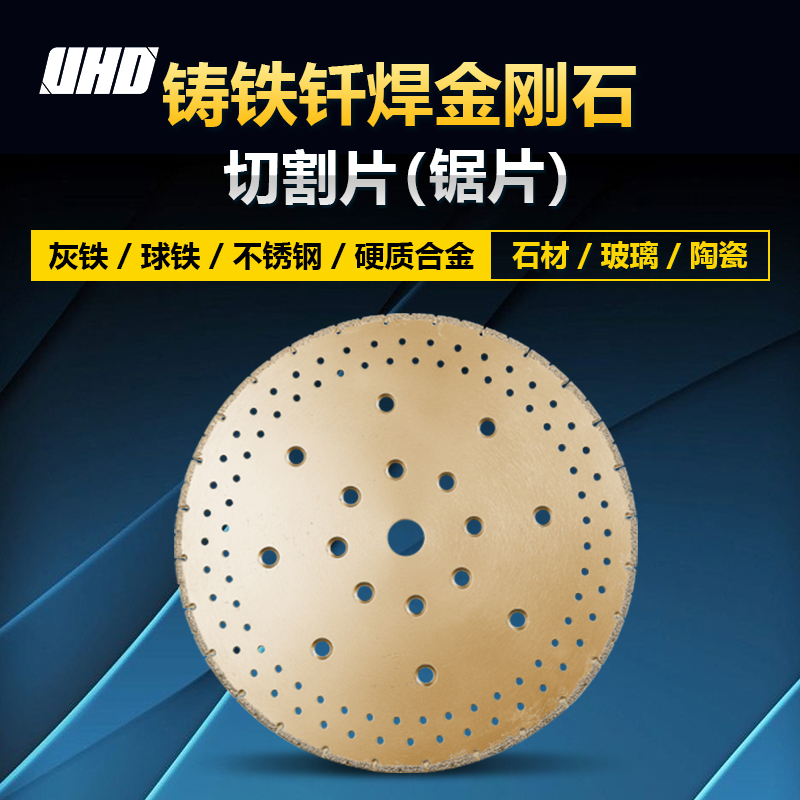

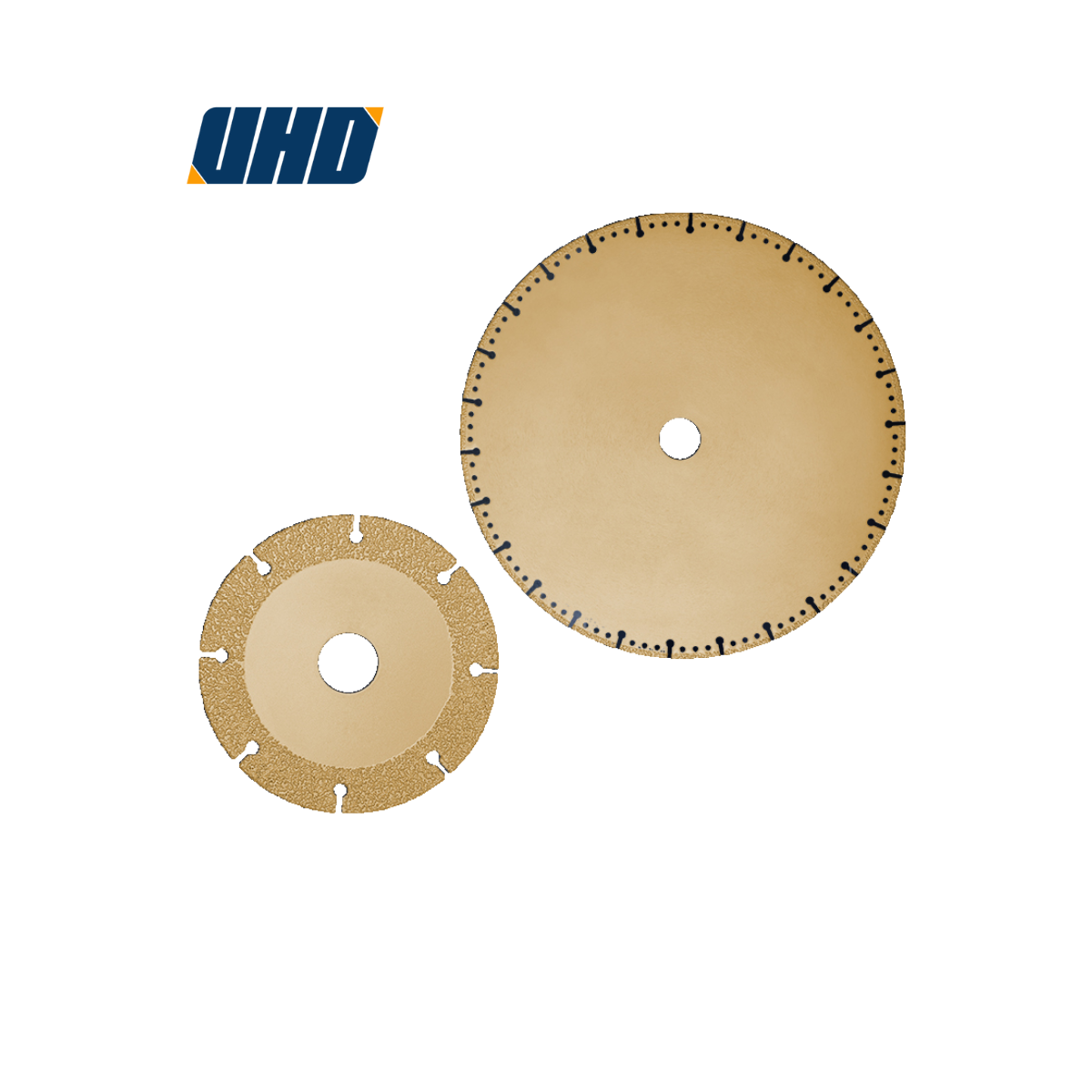

When it comes to the manufacturing process of saw blades, traditional welding and brazing are two common methods. Traditional welding has been widely used in the past, but it has some limitations. Brazing, on the other hand, offers several advantages. Brazed diamond saw blades, such as the Youde 400H brazed diamond saw blade, have better wear resistance. They can maintain sharpness for a longer time during cutting. In terms of stability, brazing can better control the thermal stress, reducing the risk of blade deformation. According to industry experts, "Brazing technology has revolutionized the field of diamond saw blade manufacturing, providing more reliable and high - performance products."

To ensure the efficient use of 400mm concrete saw blades, it is essential to know how to judge the wear of the blade head. A simple rule of thumb is that if the blade head has lost more than 30% of its original height, it is time to replace it. In addition, different environments require different cooling strategies. In dry environments, reducing the cutting speed and using high - quality lubricants can help reduce heat. In wet environments, ensuring a stable water supply and proper water pressure is crucial.

In a certain high - rise building demolition project, the use of dry cutting mode with Youde 400H brazed diamond saw blades led to a 30% increase in cutting efficiency. This data clearly shows that with the right saw blade and cutting mode, significant improvements in construction efficiency can be achieved.

Q: Which is better, dry cutting or wet cutting for 400mm concrete saw blades?

A: It depends on the specific working conditions. Dry cutting is suitable for water - free environments, while wet cutting is better for heat reduction and long - term use.

Q: How can I tell if the blade head is worn out?

A: If the blade head has lost more than 30% of its original height, it needs to be replaced.

Q: What are the advantages of brazed diamond saw blades?

A: Brazed diamond saw blades have better wear resistance, stability, and thermal stress control ability.

Are you looking for high - performance 400mm concrete saw blades? The Youde 400H brazed diamond saw blade is your ideal choice. It has been proven in multiple large - scale infrastructure projects. Click here to learn more.