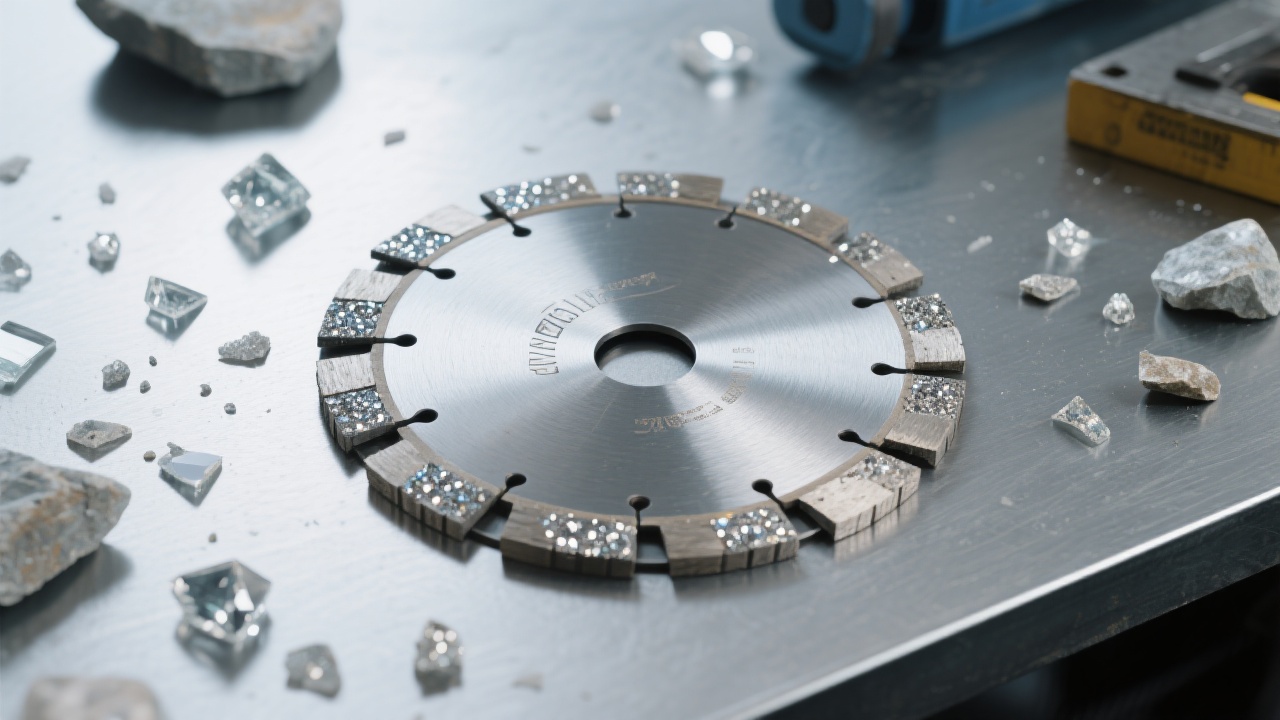

In the international stone processing market, the 400mm brazed diamond saw blade developed by Henan Youde Superhard Tools Co., Ltd. stands out with its unique design and application advantages. This article will conduct an in - depth analysis of its design features and application superiority.

The optimization of the cutter head arrangement is one of the key design features of this saw blade. Through scientific design, the cutter heads are evenly distributed on the saw blade, which can effectively disperse the cutting force. For example, compared with traditional saw blades, the optimized cutter head arrangement can reduce the cutting force by about 20%, thereby reducing the vibration and noise during the cutting process.

The matching of the matrix material is also crucial. The alloy matrix used in this saw blade has high strength and good toughness. It can withstand the high - frequency impact during the cutting process. Tests have shown that under the same cutting conditions, the service life of this saw blade with a well - matched matrix material is about 1.5 times that of ordinary saw blades.

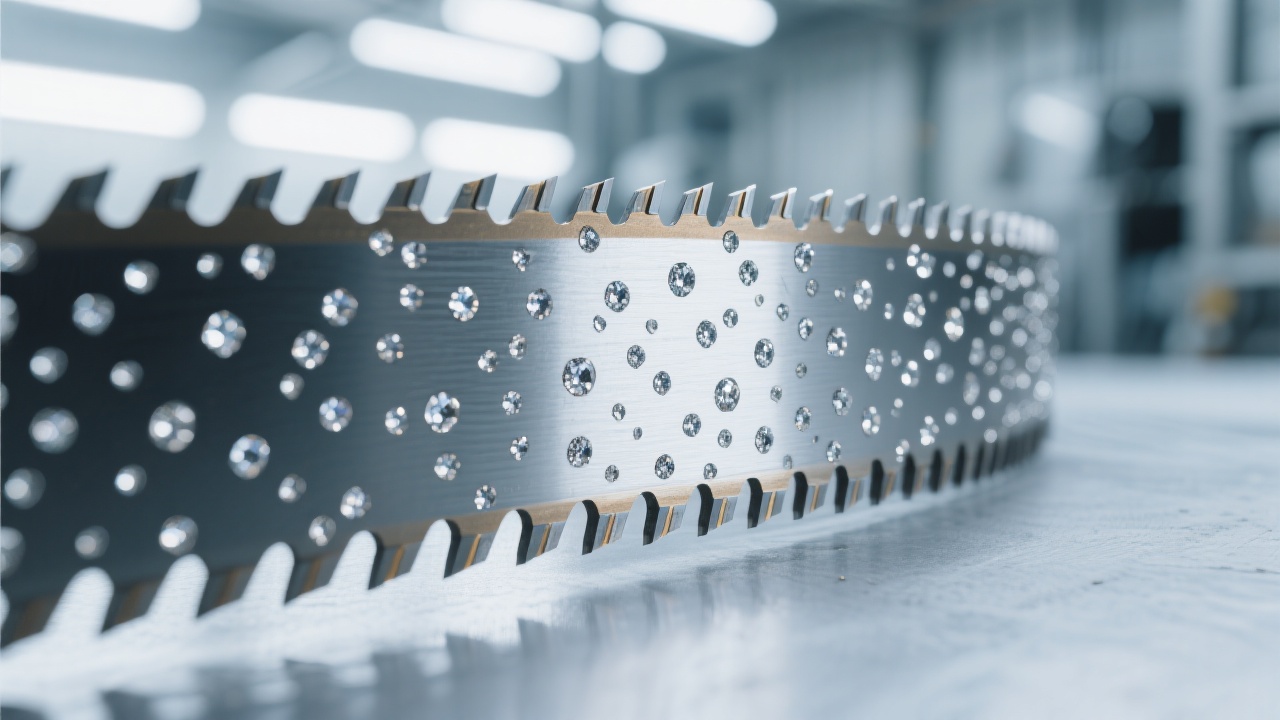

The advanced brazing process is another highlight. This process can firmly bond the diamond cutter head to the matrix, ensuring the stability of the cutter head during high - speed rotation. It can reduce the probability of cutter head falling off by more than 30%, which is of great significance for improving the safety and durability of the saw blade.

In the actual stone processing and construction projects, the 400mm brazed diamond saw blade has shown excellent performance. For instance, in a large - scale stone processing factory in Italy, after using this saw blade, the cutting noise was reduced from about 90 decibels to less than 80 decibels, which greatly improved the working environment for workers.

The control of vibration also has a positive impact on the cutting accuracy. In a building construction project in the United States, due to the low vibration of this saw blade, the cutting error was controlled within ±0.5mm, which met the high - precision requirements of the project.

The reasonable setting of parameters is also an important factor affecting the performance of the saw blade. Different stone materials and cutting thicknesses require different parameter settings. For example, when cutting granite, a relatively low feed rate and a higher rotation speed are required. Through a large number of experiments, the company has summarized a set of parameter setting schemes suitable for different working conditions, which can help workers achieve efficient cutting.

Based on the experience of front - line workers, some practical operation skills have been summarized. For example, before starting the saw blade, it is necessary to check whether the installation is firm; during the cutting process, it is necessary to ensure sufficient cooling water to prevent the saw blade from overheating. In addition, some common fault identification methods are also provided. For example, if abnormal noise or vibration occurs during the cutting process, it may be due to cutter head wear or improper parameter settings.

In conclusion, the 400mm brazed diamond saw blade of Henan Youde Superhard Tools Co., Ltd. has significant advantages in design and application. If you want to learn more about the technical details of this product, please visit our technical column for in - depth exploration, where you can find more scientific solutions to improve cutting efficiency.