In today’s industrial manufacturing landscape, procurement managers and production supervisors continually seek cutting tools that deliver exceptional durability and efficiency, especially when processing demanding materials like gray cast iron and stainless steel. The ZS400H brazed diamond saw blade emerges as a transformative solution, enabling enterprises to slash operational costs and significantly improve throughput.

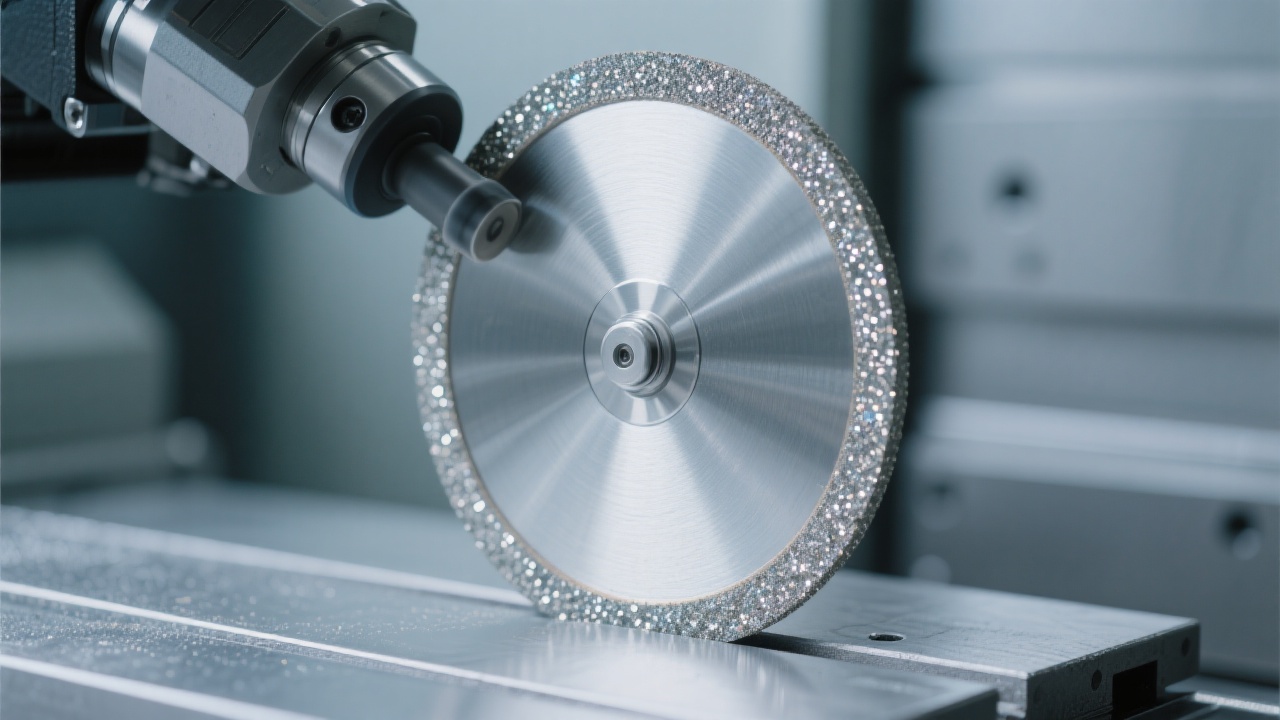

The ZS400H blade’s competitive edge lies in its integration of high-grade diamond particles embedded within a manganese steel substrate. This specialized structure ensures remarkable hardness and toughness, making it highly resistant to premature wear and deformation. The advanced brazing technique secures diamond grains firmly, extending the blade’s service life up to 3 times longer compared to conventional segmented or laser-weld blades.

Furthermore, the blade’s optimized design minimizes vibration and heat buildup during cutting, directly contributing to improved blade stability and precision. This reduces the probability of workpiece damage, a frequent concern in multi-material processing lines.

A medium-sized industrial manufacturing facility specializing in automotive component production recently adopted the ZS400H blade for their gray cast iron cutting processes. After six months of continuous operation, key performance indicators dramatically shifted:

| Metric | Traditional Blade | ZS400H Blade |

|---|---|---|

| Blade replacement frequency | Every 10 days | Every 30 days |

| Dust & particle emission reduction | Baseline | 50% reduction |

| Cutting speed and precision | Standard | 20% faster, ±0.1mm accuracy |

“Switching to the ZS400H blade was a game changer for our production. The longer lifespan and cleaner cutting environment not only cut down our downtime but also improved workplace safety dramatically.”

— Production Manager, Industrial Co.

Beyond the performance metrics, the ZS400H saw blade contributes substantially to cost control. Extending the blade lifespan by a factor of three translates directly into lower purchasing frequency and less machine downtime for blade changes—painting a clear picture of resource optimization.

Additionally, the marked reduction in dust emissions by approximately 50% aligns with stringent modern occupational health and safety norms. Cleaner operations reduce expenditures related to environmental filtration systems and mitigate employee health risks, which is vital in ISO-certified factories.

When evaluating upgrades to cutting tools, decision makers must balance cost, reliability, and regulatory compliance. The ZS400H blade offers an integrated value proposition — it is not just a saw blade but a comprehensive production upgrade solution that lowers total cost of ownership while improving operational excellence.

For enterprises aiming to maintain competitive advantage via smart tooling choices, the data-backed advantages of ZS400H render it a compelling candidate worth trialing. In an era where “let every cut be worry-free and efficient” is more than a slogan—it’s an operational imperative.

To further illustrate the performance gains, a simplified lifespan comparison shows how ZS400H significantly outperforms typical segmented blades in demanding industrial use cases:

Such a leap in blade longevity not only reduces direct procurement costs but also improves production planning, enabling manufacturers to run longer uninterrupted shifts.

Another strategic benefit lies in the environmental impact reduction. ZS400H’s optimized cutting reduces airborne particulate matter by half compared to legacy tools. This improvement directly contributes to:

The ZS400H blade’s design specifically targets challenging substrates like gray cast iron and stainless steel, materials notorious for rapid tool degradation. Customers report consistently tight dimensional tolerances, with cutting accuracy improving by up to 20%, reducing rework and scrap.

This reliable precision ensures assembly line smoothness and enhances final product quality, aligning perfectly with lean manufacturing and Six Sigma objectives.