When tackling concrete cutting projects, from high-rise demolition to bridge repairs, selecting the right saw blade dramatically influences not only your operational efficiency but also overall safety. This guide helps you navigate the critical parameters — material hardness, cutting depth, and work environment — to optimize your blade choice, focusing on the top-performing 400mm brazed diamond saw blade engineered for both wet and dry cutting applications.

First, understand your material’s hardness. Granite, reinforced concrete, and masonry require blades with superior abrasion resistance and impact toughness. Secondly, cutting depth determines blade diameter: 400mm blades deliver up to 120mm cutting depth, suitable for most construction demolition and repair works. Lastly, factor in the operating environment — dry cutting demands excellent heat dissipation and wear resistance, while wet cutting leverages water cooling for longer blade life and cleaner cuts.

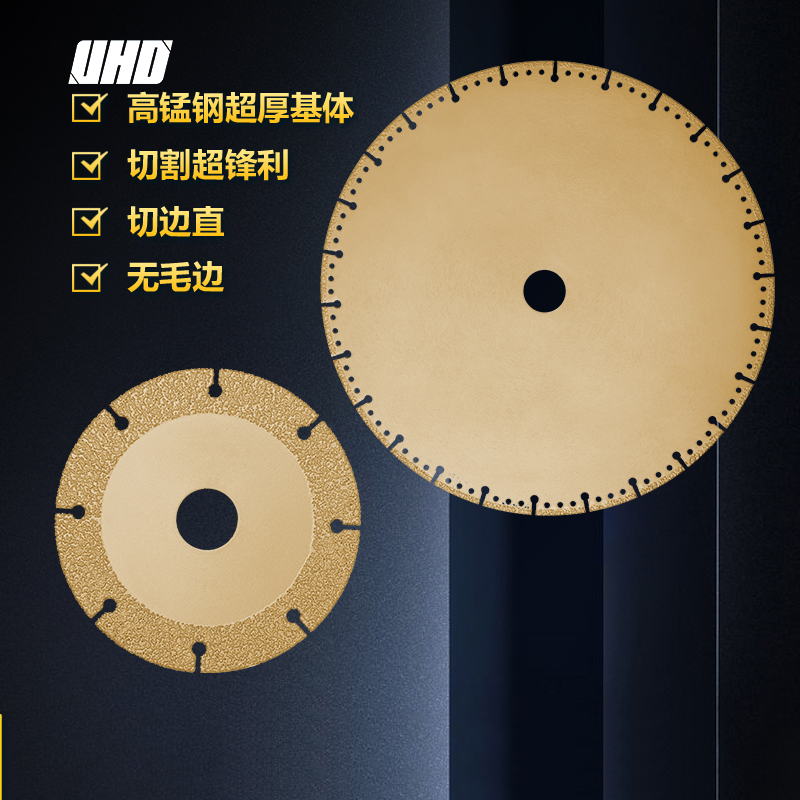

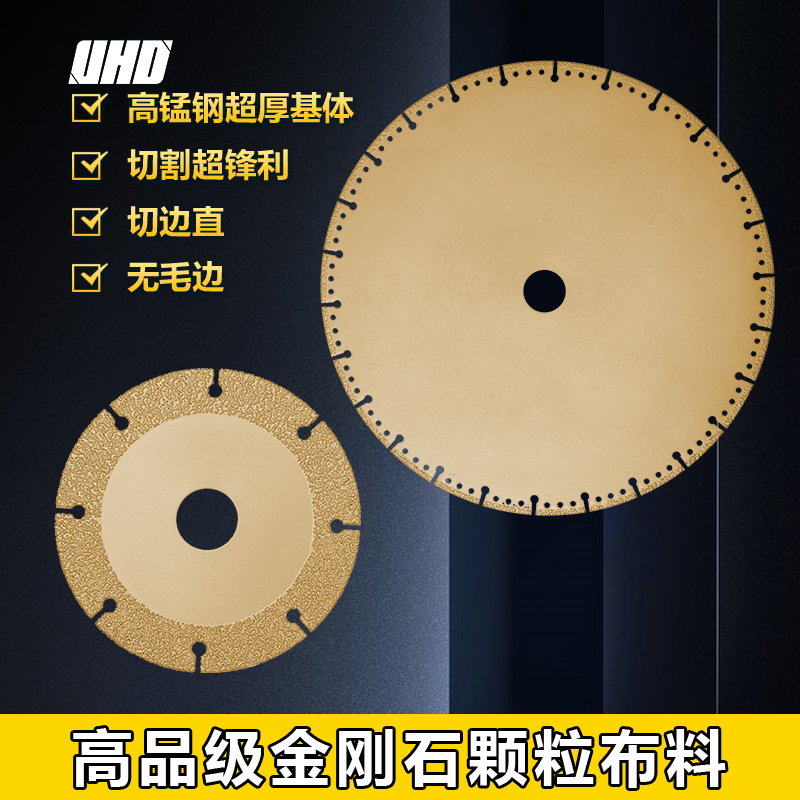

The 400mm brazed diamond saw blade is the industry go-to in challenging scenarios:

Brazing technology secures diamond segments to the steel core with a high-strength alloy, resulting in superior mechanical bonding compared to conventional welding. This difference translates to:

| Performance Metric | Brazed Diamond Blade | Traditional Welded Blade |

|---|---|---|

| Segment Retention Strength | Up to 30% higher | Prone to segment flaking |

| Wear Resistance | +25% longer lifespan | Faster abrasion under high friction |

| Impact Shock Tolerance | Superior stability in harsh conditions | Segment detachment risk |

This improved bonding also helps reduce downtime due to blade failures—data from multiple projects show approximately a 20% increase in cutting efficiency and up to 30% reduction in blade replacements when switching to brazed blades.

Monitoring blade condition is crucial. Look for uneven segment wear, chipping, or exposed core steel — clear signs that replacement is due. For dry cutting, ensure your blade’s cooling features are optimized to prevent overheating, which shortens lifespan. Wet cutting is preferable for extensive or heavy-duty operations, where water cooling can reduce dust and enhance blade longevity.

Remember, applying appropriate cooling prevents warping and maintains cut quality. Using water sprays or integrated water feed systems helps ensure stable operation, and reduces personal protective equipment requirements by minimizing dust emissions.

Trials conducted on projects involving granite and reinforced concrete found that using a 400mm brazed diamond saw blade boosted cutting speed by an average of 18-22% compared to traditional blades. Moreover, operational lifespan extended by roughly 30%, significantly lowering ongoing costs.

Integrating these blades into your workflow means fewer blade swaps, shortened downtime, and ultimately, smoother project timelines.

Because of its unmatched durability and consistent performance, the 400H brazed diamond saw blade has already become the trusted choice for thousands of construction projects worldwide.

Discover the 400H Brazed Diamond Saw Blade Now & Elevate Your Cutting Efficiency