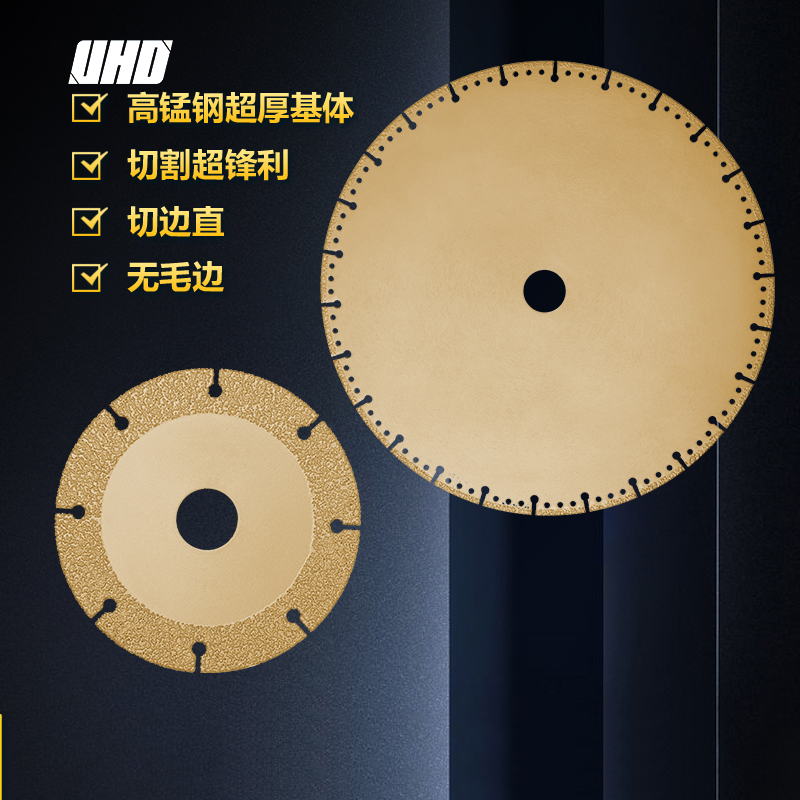

Concrete cutting professionals understand that the choice of cutting blades profoundly impacts project efficiency, safety, and costs. Among blade types, 400mm brazed diamond concrete cutting blades stand out for superior durability and precision. This guide dives deep into the application nuances of these blades—focusing on material hardness, cutting depth, and dry versus wet cutting environments—helping construction experts make informed, data-driven decisions on-site.

The hardness of concrete materials varies significantly based on composition and curing age, impacting blade wear rate and cutting efficiency. Typical concrete hardness ranges from 25 to 45 MPa compressive strength, with high-performance mixes reaching above 50 MPa. A 400mm brazed diamond blade—characterized by a diamond grit bonded through advanced brazing technology—delivers robust cutting in these ranges.

For depths up to 150mm, these blades maintain optimal cutting speed and minimal wear. Beyond this, blade selection must account for torque demands and motor power capacity to avoid excessive strain or overheating.

Selecting the appropriate cooling method is critical. Wet cutting with continuous water flow reduces heat generation, preserves diamond integrity, and minimizes dust—crucial in urban or enclosed environments adhering to OSHA standards limiting respirable silica dust exposure.

Conversely, dry cutting is preferred in areas lacking water resources or where electrical tools aren't feasible. Brazed diamond blades demonstrate enhanced heat resistance compared to traditional welded blades due to their metallurgical bond, thereby extending lifespan under dry cutting conditions. Yet, operators must employ intermittent cutting cycles and dust extraction to prevent overheating.

| Cutting Environment | Cooling Method | Optimal Application |

|---|---|---|

| Wet Cutting | Continuous Water Spray | High dust control, maximum blade life in urban or indoor sites |

| Dry Cutting | Intermittent Operation + Dust Extraction | Remote sites, limited water or electrical supply |

Timely identification of blade wear is indispensable to maintaining cutting accuracy and safety. Common indicators include:

Cross-referencing these signs with cutting data (feed speed, RPM, noise changes) enables predictive maintenance scheduling. As an example, high-rise demolition projects documented blade wear acceleration by 15% when operating without wet cooling continuously over 4 hours.

Brazed diamond blades employ a metallurgical bonding process that exceeds traditional welded blade durability. This method enhances segment retention and resistance to segment loss during intensive applications. Studies report a 20% improvement in lifespan and up to 15% higher cutting speed efficiency.

These performance gains translate into fewer blade replacements and downtime, crucial on projects like bridge maintenance or industrial flooring where continuous operation is pivotal.

Real-world applications of 400mm brazed diamond blades span:

Optimizing blade and cooling choices per scenario significantly raises cutting efficiency—up to 25% time savings reported in recent case studies.