Stone processing is a crucial industry, but it often encounters several common pain points. High levels of dust, severe burrs, and rapid blade wear are among the most significant issues that plague stone processing enterprises. These problems not only harm the working environment and the health of operators but also increase production costs and reduce efficiency.

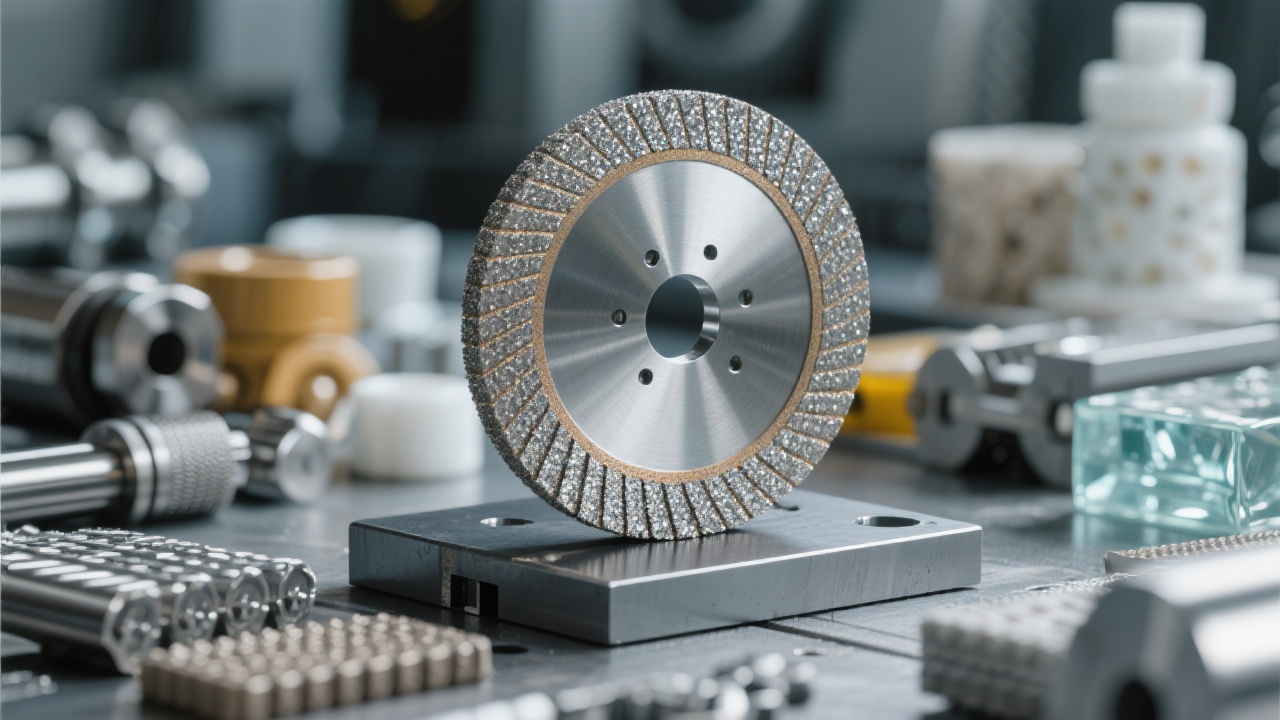

Enter the UHD brand's high - performance welded diamond cutting disc 400, a game - changing solution designed to address these long - standing problems. This cutting disc is a product of innovation and advanced technology, aiming to revolutionize the stone cutting process.

First and foremost, the UHD cutting disc 400 comes with ISO certification, which is a testament to its high - quality manufacturing process and strict quality control. This certification ensures that the product meets international standards, giving enterprises the confidence to use it in their production lines.

The cutting disc is equipped with ultra - sharp diamond abrasives. Diamond is known for its extreme hardness and cutting ability. The use of such high - quality abrasives allows the cutting disc to cut through stone materials with ease, ensuring a smooth and efficient cutting process.

Moreover, it features a high - manganese steel base. This base provides excellent stability during the cutting process. High - manganese steel is known for its toughness and resistance to wear, which helps to maintain the shape and performance of the cutting disc even under high - stress conditions.

When compared to traditional resin blades, the UHD cutting disc 400 truly shines. Traditional resin blades often have a short lifespan due to their relatively soft materials and simple manufacturing processes. In contrast, the UHD cutting disc 400 has a lifespan that is more than 3 times longer. This means that enterprises can use the same cutting disc for a much longer period, significantly reducing the frequency of blade replacements.

As a result, the overall cost of operation is greatly reduced. Enterprises no longer need to spend a large amount of money on constantly purchasing new blades, which directly contributes to lower production costs and higher profit margins.

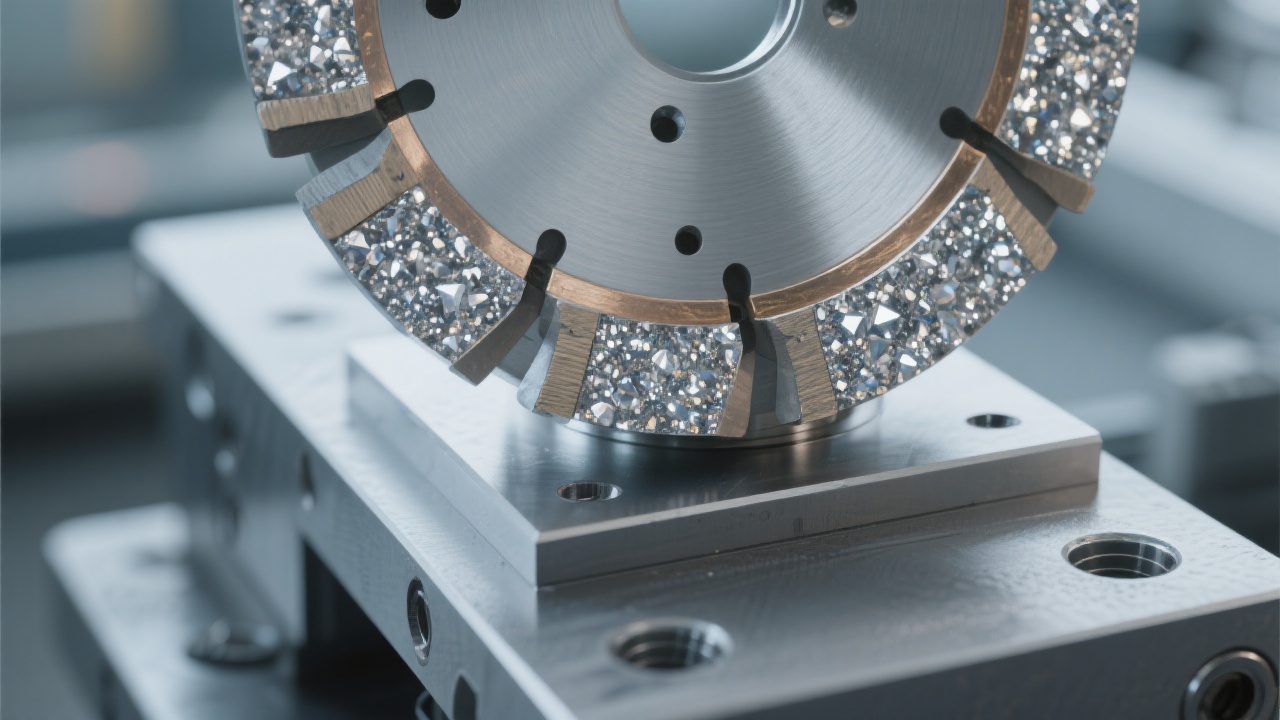

The unique tooth profile and edge design of the UHD cutting disc 400 play a crucial role in reducing dust and burrs. The tooth profile is carefully designed to ensure that the cutting disc can cut through the stone in a more efficient and controlled manner. When the cutting disc rotates, the teeth break the stone material layer by layer, rather than causing a large - scale crushing that generates a lot of dust.

The precision - cut edge technology further enhances the cutting quality. It allows for a smooth and clean cut, minimizing the formation of burrs. The principle behind this is similar to how a sharp and well - designed knife can cut through food without leaving rough edges. This not only improves the quality of the cut stone products but also reduces the need for secondary processing.

To illustrate the effectiveness of the UHD cutting disc 400, let's look at some real - world case studies. A stone processing factory in Italy was facing severe problems with dust pollution and high blade replacement costs. After switching to the UHD cutting disc 400, they noticed a significant reduction in dust levels in the workshop. The air quality improved, and the health of the operators was better protected.

At the same time, the number of blade replacements decreased from once a week to once every three weeks. This not only saved them a considerable amount of money but also increased the overall production efficiency by reducing the downtime caused by blade changes. The quality of their stone products also improved, with fewer burrs and a smoother finish.

For stone processing enterprises, the UHD cutting disc 400 offers significant value. It helps to improve the quality of products, making them more competitive in the market. The reduction in dust and burrs means that the final products have a better appearance and meet higher quality standards.

By reducing the frequency of blade replacements and lowering the overall cost of operation, the cutting disc also enhances the efficiency and profitability of enterprises. It allows enterprises to produce more with less, maximizing their resources and achieving better results.

Don't miss out on the opportunity to upgrade your stone cutting process. 立即联系我们,体验UHD切割片的卓越性能 and take your stone processing business to the next level.