In the realm of industrial production, cutting tools play a pivotal role. They are the workhorses that transform raw materials into finished products. According to industry statistics, up to 30% of production time can be attributed to cutting operations. Any inefficiency or failure in cutting tools can lead to significant downtime, increased maintenance costs, and reduced productivity.

Global industrial customers face various challenges when it comes to cutting tools. They need tools that can handle different materials, provide high precision, and maintain performance over long periods. Moreover, with the increasing demand for cost - effectiveness and sustainability, the choice of cutting tools becomes even more critical.

UHD Superhard Materials Tools Co., Ltd. has established innovative partnerships with universities such as Henan University of Technology. This collaboration has enabled the company to leverage the latest research and development in the field of superhard materials. By combining academic knowledge with industrial experience, UHD can create cutting - edge cutting tools.

UHD's cutting tools meet international top - level quality standards. Rigorous quality control processes are in place throughout the manufacturing process. From raw material selection to the final product inspection, every step is carefully monitored. This ensures that the tools can perform consistently under various working conditions, with a defect rate of less than 1%.

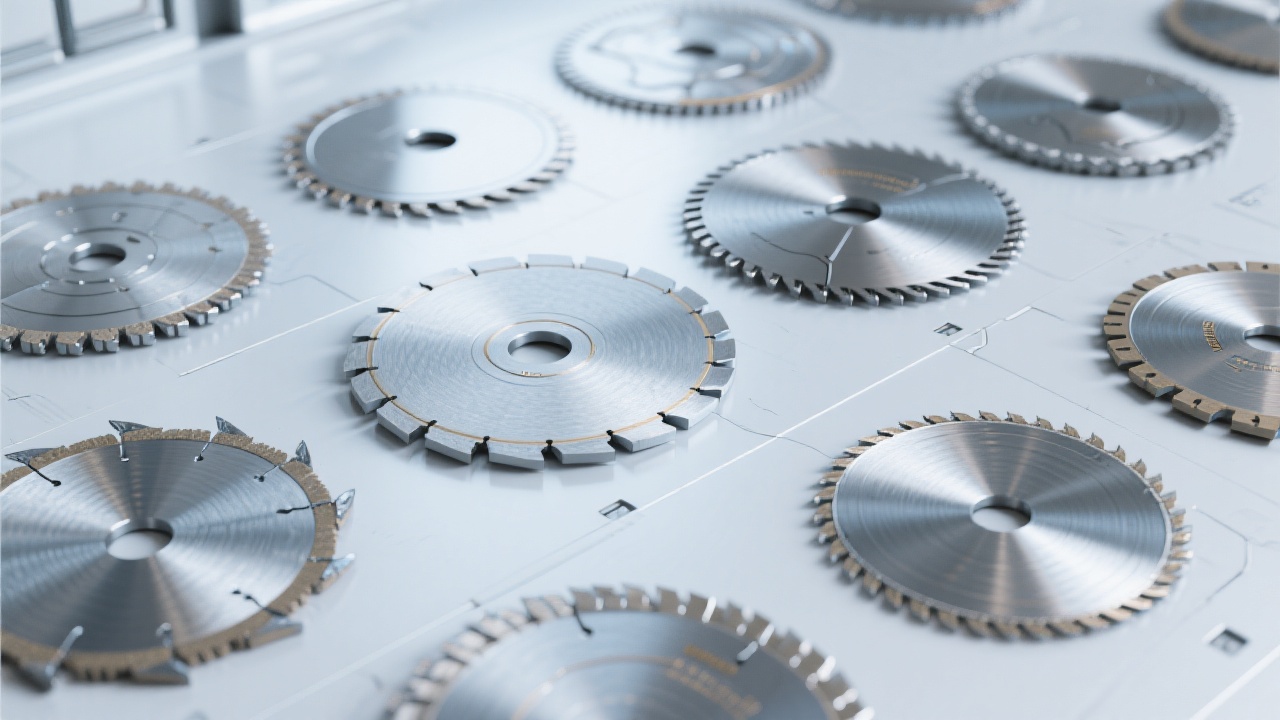

The company offers a wide range of cutting tools with precise designs. Whether it's for rough cutting or fine finishing, UHD has the right tool for the job. With over 50 different types of cutting tools in its product line, it can meet the diverse needs of global industrial customers.

Let's take a look at a real - world example. A metal processing factory in Europe was facing frequent downtime due to the poor performance of its existing cutting tools. The old tools needed to be replaced every 10 hours of operation, and the maintenance cost was as high as $5000 per month. After switching to UHD's diamond cutting tools, the situation improved significantly.

The UHD tools could operate continuously for 30 hours before requiring replacement, reducing the replacement frequency by 66%. The maintenance cost dropped to $1500 per month, a 70% reduction. In addition, the production efficiency increased by 40% as the factory could produce more products in the same amount of time.

Another customer, an automotive parts manufacturer in Asia, was struggling with low - precision cutting. The UHD cutting tools provided high - precision cutting, reducing the scrap rate from 8% to 2%. This not only saved raw materials but also improved the overall product quality.

As demonstrated by these real - world cases, UHD's cutting tools offer significant economic value and reliability. By choosing UHD, global industrial customers can enjoy a more efficient, reliable, and high - quality industrial tool solution. The long - term benefits include reduced costs, increased productivity, and enhanced competitiveness in the market.

Don't miss out on the opportunity to transform your production process. Click here to learn more about UHD's cutting tools and how they can benefit your business! We encourage you to leave your comments and questions below, and our team will be happy to assist you.