In today's fiercely competitive industrial manufacturing sector, selecting the optimal cutting tool can make a significant difference in operational efficiency and cost management. Companies worldwide are continuously seeking reliable, high-performance cutting solutions that can handle complex workpieces while reducing downtime and expenses. The ZS400H brazed diamond cutting blade emerges as a breakthrough innovation tailored for such demanding industrial applications.

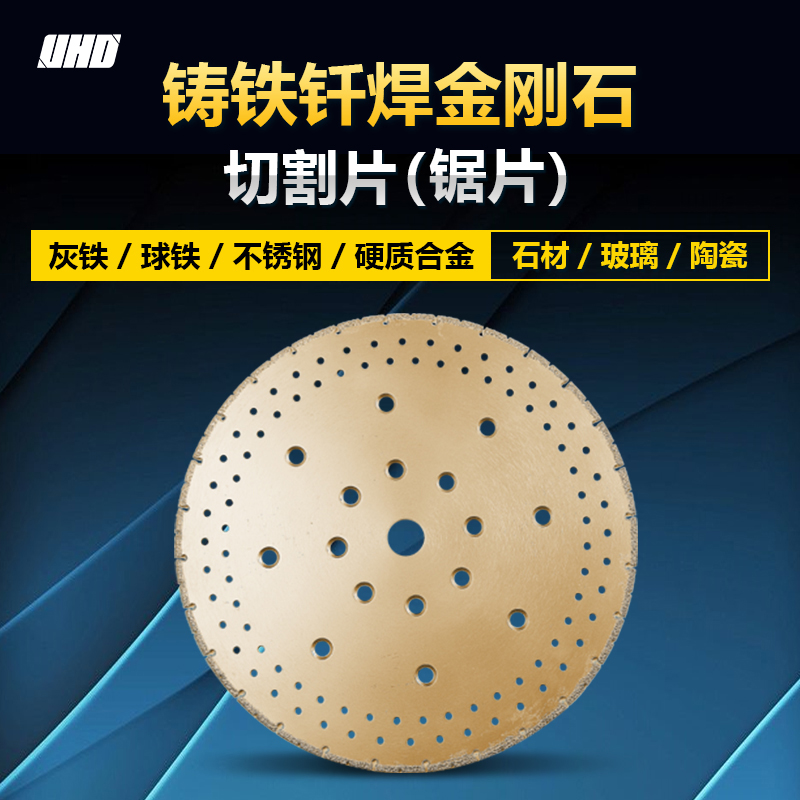

The ZS400H utilizes advanced brazed diamond technology specifically designed for cutting intricate and hard-to-machine components. Its superior composition combines premium-grade diamond particles with a high-manganese steel ultra-thick substrate. This unique construction ensures exceptional wear resistance, dimensional stability, and prolonged service life. Such characteristics make ZS400H ideal for intensive manufacturing processes where precision and endurance are paramount.

| Feature | ZS400H Specification | Benefit to Manufacturers |

|---|---|---|

| Diamond Grade | Premium High-Quality Brazed Diamonds | Increased cutting precision and blade longevity |

| Substrate Material | High Manganese Steel Ultra-Thick Base | Enhances impact resistance and reduces deformation |

| Blade Thickness | Optimized Ultra-Thick Design | Minimizes vibration for smoother cuts |

A leading industrial enterprise recently integrated ZS400H into their cutting operations targeting complex workpieces. Within the first quarter of implementation, the client reported a remarkable 30% reduction in operational cutting costs. This substantial saving is attributed to multiple factors:

Beyond cost efficiency, the cleaner operation supported by the ZS400H significantly minimizes dust and noise pollution, aligning with modern environmental and workplace safety standards – an increasingly critical factor for global manufacturers seeking sustainable production methods.

The ZS400H brazed diamond blade represents a next-generation cutting solution engineered to empower manufacturers confronting complex material challenges. Its proven ability to reduce costs by up to 30%, alongside operational efficiencies and improved environmental conditions, establishes it as a compelling option in the portfolio of high-performance industrial cutting tools.

Industrial buyers and procurement specialists prioritizing long-term value and reliability will find in ZS400H a partner for sustained productivity gains and competitive advantage.

Discover how ZS400H can lower costs, enhance precision, and optimize your cutting processes today.

Contact Our Experts Now