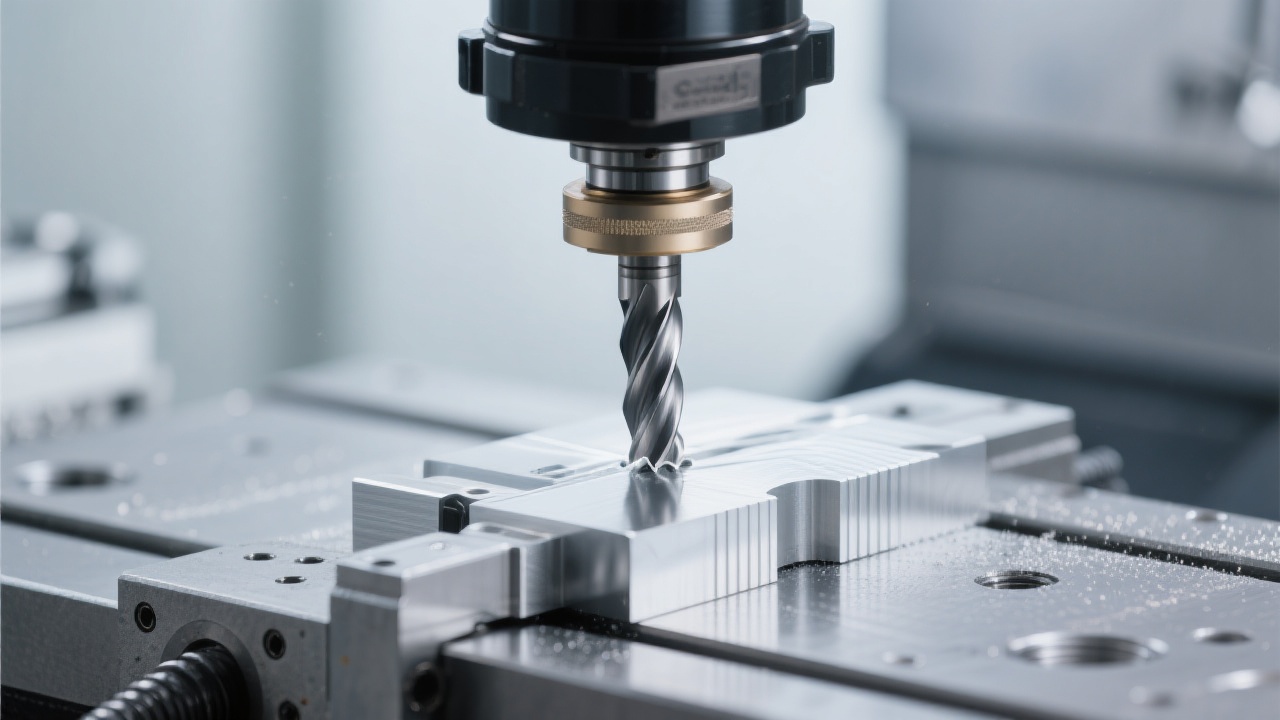

Boost Metal Cutting Efficiency with UHD High-Performance Diamond Cutting Blades

Facing challenges of low efficiency and high costs in metal and stone cutting, Henan Youde Superhard Tools Co., Ltd. proudly introduces the UHD brand's welded high-performance diamond cutting blade 400. Manufactured under ISO 9001 standards, this blade combines ultra-sharp diamond abrasives with a robust high-manganese steel base, significantly enhancing cutting stability and precision. Featuring a unique tooth design and finely engineered cutting edges, it delivers smooth, burr-free cuts and environmentally friendly low-dust operation while greatly extending blade life. This product reduces operational costs and elevates production efficiency, supported by real-world case studies and technical analysis demonstrating its exceptional performance in metal and stone processing. UHD cutting blades offer enterprises an advanced solution for efficient, high-quality cutting.

Boost Metal Cutting Efficiency with UHD High-Performance Diamond Cutting Blades

In the competitive metal and stone processing industries, achieving efficient, precise, and cost-effective cutting remains a persistent challenge. Conventional cutting tools often fall short, leading to higher downtime, frequent replacements, and inconsistent cut quality. Addressing these pain points, Henan Youde Superhard Tools Co., Ltd. under its UHD brand, proudly introduces the Welded Diamond Cutting Blade 400. Engineered to meet ISO 9001 quality standards, this blade revolutionizes cutting performance through advanced material science and design innovation.

Exceptional Core Features Driving Performance

The UHD Diamond Cutting Blade 400 capitalizes on a unique combination of components to deliver superior cutting results:

- Ultra-sharp Diamond Abrasives: High-grade synthetic diamond particles provide outstanding hardness and wear resistance, ensuring faster cutting speeds and cleaner cuts.

- Robust High-Manganese Steel Base: Integrating a high-manganese steel substrate enhances blade toughness and durability, reducing risks of deformation under heavy loads.

- Precisely Engineered Tooth Profile: The distinctive tooth geometry minimizes cutting resistance, lowers energy consumption, and delivers smooth, burr-free edges.

Comparative Advantages Over Traditional Resin Blades

Unlike conventional resin bond blades, UHD's welded diamond blade boasts:

| Performance Metric |

UHD Diamond Cutting Blade 400 |

Traditional Resin Blade |

| Operational Lifespan |

Up to 3x longer |

Standard durability |

| Cutting Speed |

20-30% faster |

Baseline speed |

| Cut Quality |

Smooth, no burrs |

Rough edges, requires rework |

| Dust and Debris |

Low dust emission |

Higher dust, environmental concern |

| Cost Efficiency |

Lower total cost of ownership |

Higher replacement costs |

Real-world Application Cases Demonstrate Excellence

Numerous industrial partners have integrated the UHD Diamond Cutting Blade 400 into their metal and stone processing workflows with impressive results:

- Automotive Parts Manufacturer in Germany: Achieved a 25% reduction in cutting cycle time while eliminating post-cut burr processing on critical metal chassis components.

- Stone Fabrication Plant in Italy: Reported a 40% increase in blade lifespan and significant reduction in airborne silica dust, enhancing worker safety.

- Construction Equipment Supplier in the USA: Noted consistent cut quality across diverse metal alloys, cutting down scrap rates by 15% and lowering overall production costs.

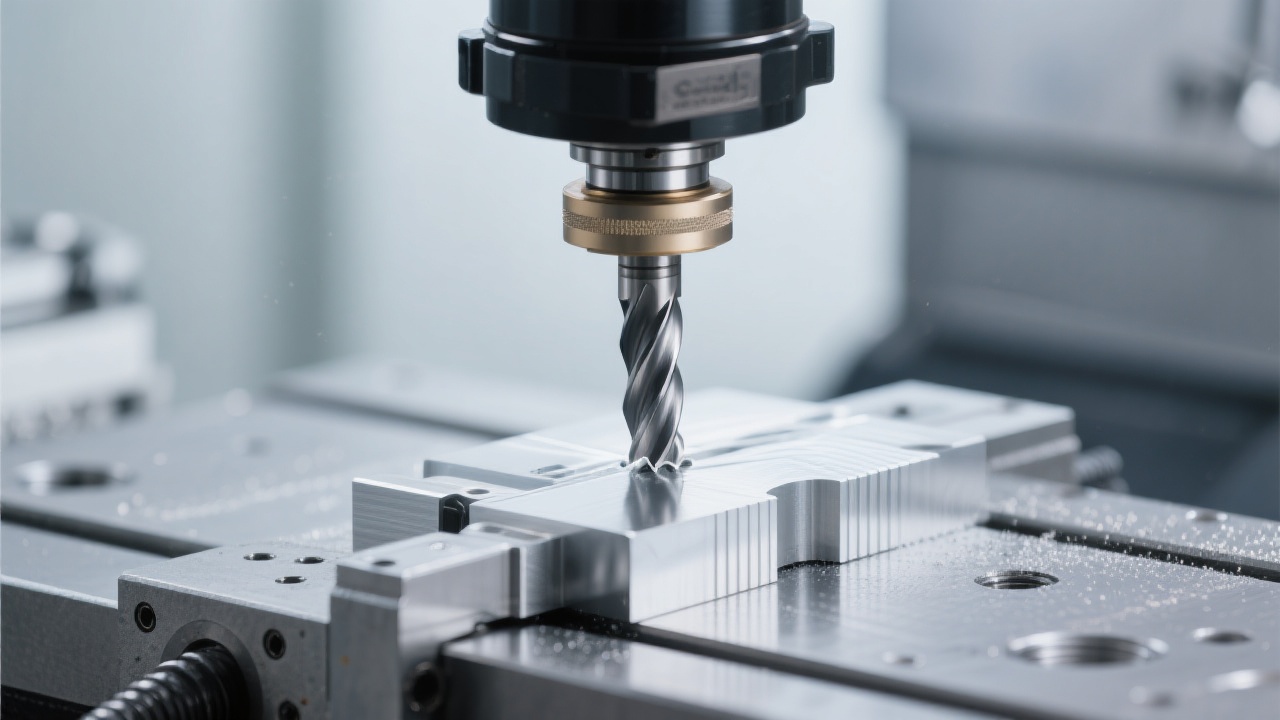

Innovative Design for Reduced Dust and Superior Precision

The distinctiveness of UHD's cutting blade lies in its intricate tooth geometry and carefully sharpened cutting edges. This design facilitates:

- Minimized Heat Generation: Lower friction reduces blade warping risks and preserves diamond integrity.

- Cleaner, Dust-Reduced Environment: Efficient debris ejection lowers airborne particles by approximately 30%, complying with stricter environmental standards.

- Consistent Burr-Free Cuts: Reduces or eliminates secondary finishing, increasing throughput.

Driving Production Efficiency and Cost Savings for Your Business

Deploying UHD's high-performance diamond cutting blades translates directly into tangible business benefits:

| Up to 30% Improvement |

In production throughput via faster cutting speeds |

| Reduction of 25% |

In operational costs due to extended blade longevity and less waste |

| Significant Enhancement |

In product quality, directly boosting customer satisfaction |

| Compliance with |

Environmental safety norms due to low dust emission |

UHD’s dedication to stringent ISO 9001 certification ensures consistent quality control at every manufacturing stage. This reliability empowers businesses globally to confidently enhance their cutting operations with precision and efficiency.