In today’s highly competitive industrial manufacturing market, selecting the right cutting tools is critical for maintaining productivity and reducing operational costs. Among the many options available, UHD Ultra-Hard Materials Co., Ltd.’s ZS400H brazed diamond saw blade has emerged as a top choice for businesses looking to enhance performance while minimizing expenses.

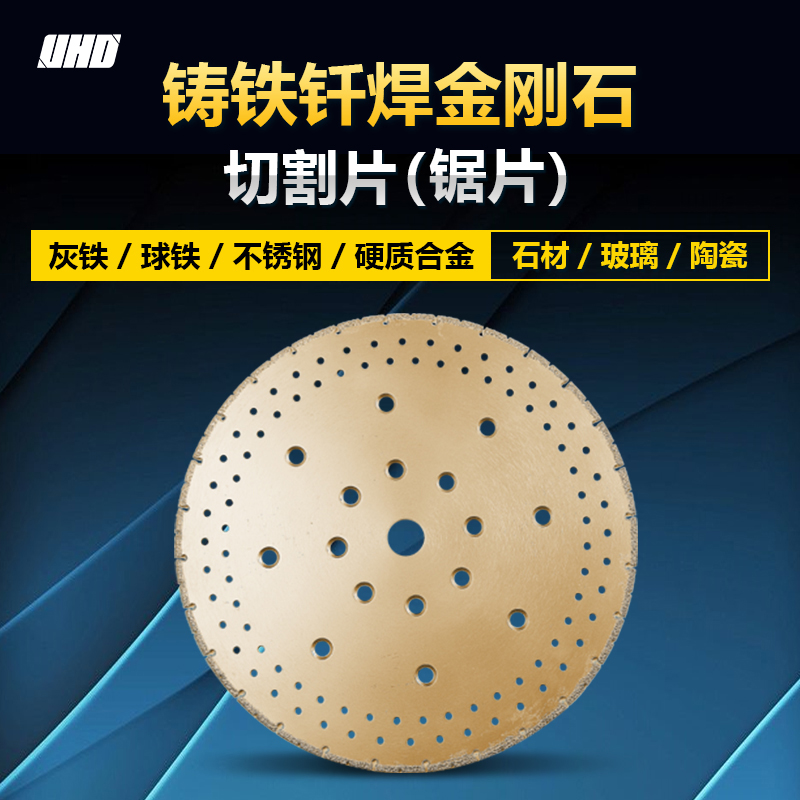

The ZS400H is engineered with high-grade diamond particles and a thick manganese steel base, ensuring exceptional wear resistance, sharpness, and stability. This combination makes it ideal for cutting complex workpieces such as ceramics, glass, concrete, and other hard materials. The blade’s design allows for smooth and precise cuts, significantly reducing the need for frequent replacements.

Compared to traditional resin blades, the ZS400H offers a longer service life, lower replacement frequency, and reduced operating costs. Its advanced technology also ensures smoother cutting processes and less dust generation, making it an environmentally friendly option that meets global sustainability standards.

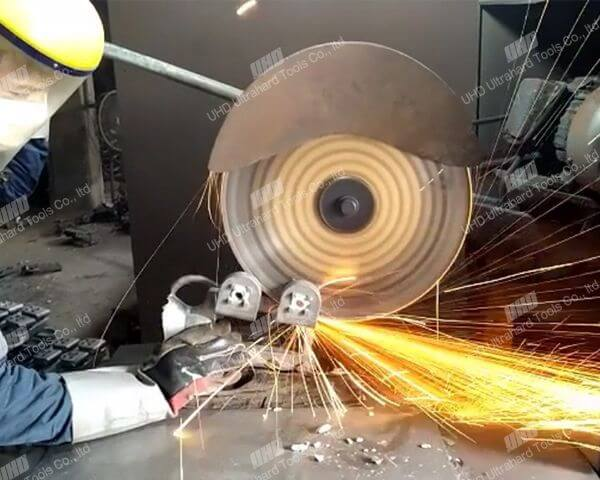

Many manufacturers have reported significant improvements in their production efficiency after switching to the ZS400H. For example, one customer in the construction industry noted that their blade replacement frequency dropped by 60% compared to previous models. This directly translated into cost savings of over $12,000 per year.

Another user from the glass processing sector highlighted the blade’s ability to maintain consistent performance even during long shifts. With less downtime and fewer interruptions, their overall production output increased by 25%, demonstrating the blade’s impact on operational efficiency.

| Feature | Traditional Resin Blade | ZS400H Brazed Diamond Blade |

|---|---|---|

| Lifespan | Shorter | Longer |

| Cutting Speed | Moderate | High |

| Dust Emission | Higher | Lower |

| Cost Per Cut | Higher | Lower |

One leading manufacturer in the ceramic industry shared their experience: “After switching to the ZS400H, we saw a noticeable improvement in both the quality of our cuts and the consistency of our production. Our maintenance team spends less time replacing blades, which has helped us reduce labor costs.”

Another user from the metalworking sector added, “The ZS400H not only lasts longer but also produces cleaner cuts with minimal dust. This has made our workshop environment safer and more compliant with environmental regulations.”

The ZS400H brazed diamond saw blade is a proven solution for companies seeking to optimize their cutting operations. With its superior durability, high cutting efficiency, and eco-friendly design, it helps manufacturers achieve sustainable growth and maintain a competitive edge in the global market.

Don’t miss the opportunity to upgrade your cutting tools and transform your production process. Discover the power of the ZS400H today and take your business to the next level.

Explore ZS400H and Boost Your Production Efficiency