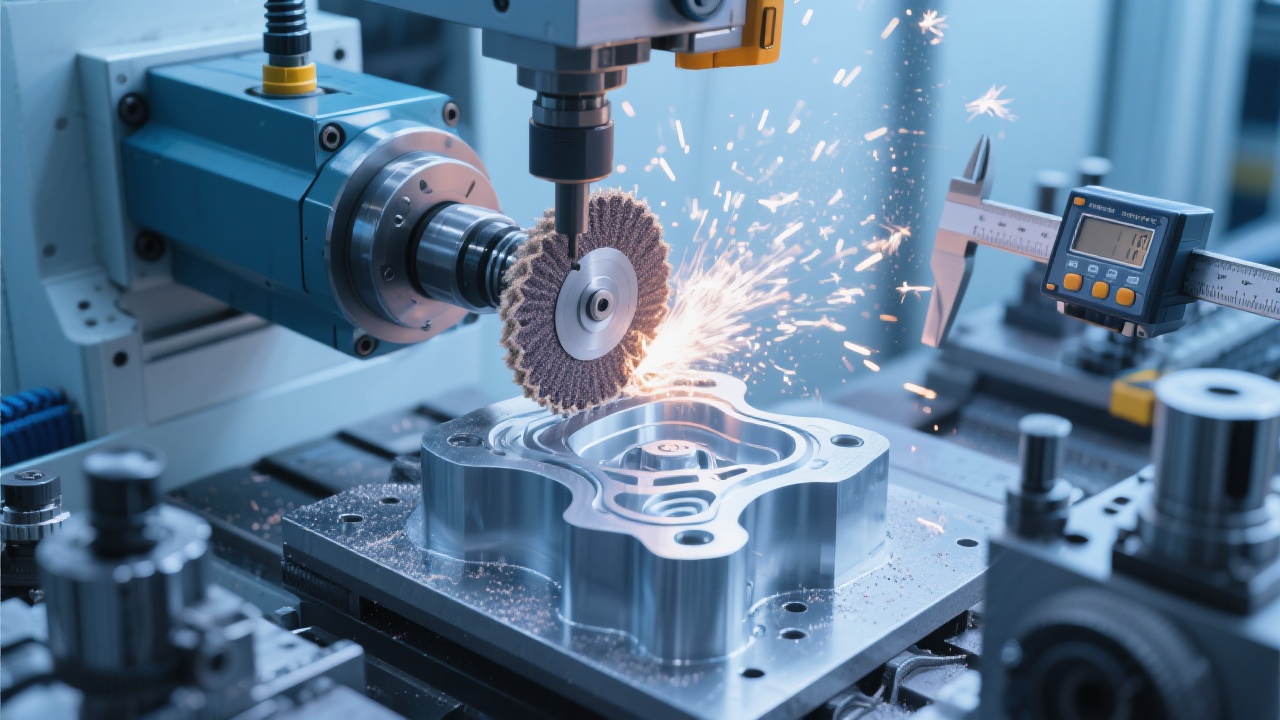

In today's fiercely competitive industrial manufacturing landscape, selecting robust, efficient cutting tools is no longer optional—it's a strategic imperative. The ZS400H tungsten carbide welded diamond saw blade, engineered with a super-thick high-manganese steel base, emerges as a game-changer for enterprises committed to boosting cutting precision, minimizing downtime, and advancing green operations.

The ZS400H blade integrates premium grade diamond grit, known for exceptional hardness and wear resistance, with a high-manganese steel core remarkably thicker than conventional bases. This robust platform, measuring up to 35 mm in thickness compared to typical ~15 mm resin-backed blades, offers enhanced stability, vibration reduction, and impact resilience during high-speed cutting tasks.

High-manganese steel’s unique molecular structure endows the blade with superior toughness — crucial for maintaining edge integrity when slicing through tough, abrasive materials such as gray cast iron and stainless steel.

Compared to traditional resin-based saw blades, the ZS400H offers an average lifespan extension of 4 to 5 times, delivering a substantial reduction in replacement frequency and associated labor costs. Moreover, operational dust emissions decrease by up to 60%, aligning with increasingly stringent environmental regulations and workplace safety standards.

| Feature | ZS400H Saw Blade | Traditional Resin Blade |

|---|---|---|

| Base Thickness | 35 mm | ~15 mm |

| Average Lifespan | Up to 5x longer | Standard |

| Dust Emissions | 60% Reduction | High |

| Cutting Efficiency | Up to 30% faster | Baseline |

"Since switching to the ZS400H blades, we have witnessed a dramatic reduction in downtime and maintenance overhead. The increased cutting speed and blade longevity have transformed our production line efficiency."

- John M., Production Manager, Eastern Foundry Co.

Industrial environments processing abrasion- and hardness-challenging materials such as gray cast iron and stainless steel have reported consistent superior cutting stability using the ZS400H blade. Its thick high-manganese steel base absorbs torque shock effectively, preventing deformation and reducing blade wobble, enabling clean, precise cuts with fewer rejects.

Ensuring peak performance from the ZS400H saw blade requires regular, straightforward maintenance:

By following these maintenance guidelines, companies can extend the blade’s operational lifespan by up to 30%, further optimizing cost efficiency.

The ZS400H welded diamond saw blade with super-thick high-manganese steel base is not just a tool—it’s a strategic asset. Experience unparalleled stability, cut down on material waste and downtime, and embrace a sustainable, eco-friendly cutting solution. Say goodbye to frequent blade replacements and welcome a new era of stable, high-efficiency production.

Discover How ZS400H Can Revolutionize Your Cutting Workflow Today