Concrete cutting is a crucial task in various construction projects, such as high - rise building demolition, floor treatment, and bridge maintenance. Selecting the right saw blade can significantly impact the efficiency and safety of the construction process. This article focuses on the 400mm brazed diamond saw blade, providing in - depth analysis and practical guidance for construction professionals.

The two most important factors in choosing a concrete cutting saw blade are material hardness and cutting depth. The hardness of the concrete material directly affects the performance of the saw blade. Generally, harder concrete requires a saw blade with better wear - resistance and cutting ability.

For example, when cutting high - strength concrete with a compressive strength of over 60 MPa, a 400mm brazed diamond saw blade can maintain a relatively stable cutting depth. Tests have shown that in such hard concrete, a well - designed brazed diamond saw blade can achieve a cutting depth of up to 150mm, while a traditional saw blade may only reach 100mm or less.

The type of cutting operation, whether it is dry cutting or wet cutting, also has a significant impact on saw blade performance. Dry cutting is more convenient in some situations, but it generates more heat, which can accelerate blade wear. Wet cutting, on the other hand, can effectively reduce heat and extend the service life of the saw blade. Studies indicate that wet cutting can increase the service life of a 400mm brazed diamond saw blade by up to 30% compared to dry cutting.

In high - rise building demolition, the 400mm brazed diamond saw blade shows excellent performance. High - rise buildings often use high - strength concrete, and the brazed diamond saw blade can quickly and accurately cut through the concrete, improving the demolition efficiency. In a recent high - rise building demolition project, the use of 400mm brazed diamond saw blades reduced the demolition time by 20% compared to traditional saw blades.

When it comes to floor treatment, the saw blade can provide a smooth and precise cut, ensuring the quality of the floor surface. For bridge maintenance, the saw blade's high - precision cutting ability is crucial for repairing damaged bridge structures. In bridge deck repair projects, the 400mm brazed diamond saw blade can cut through the old concrete layer cleanly, facilitating the subsequent repair work.

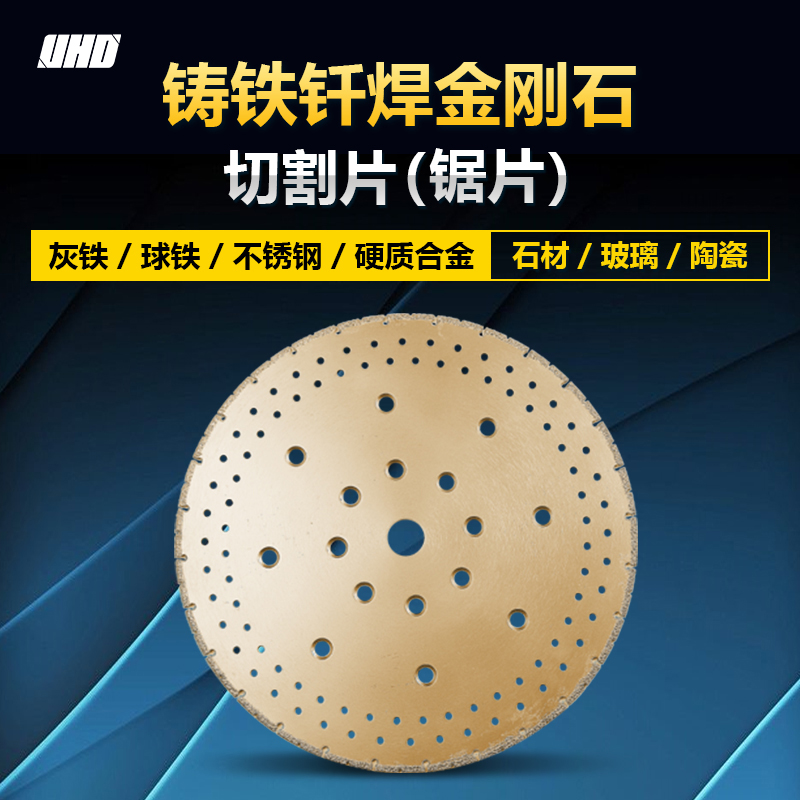

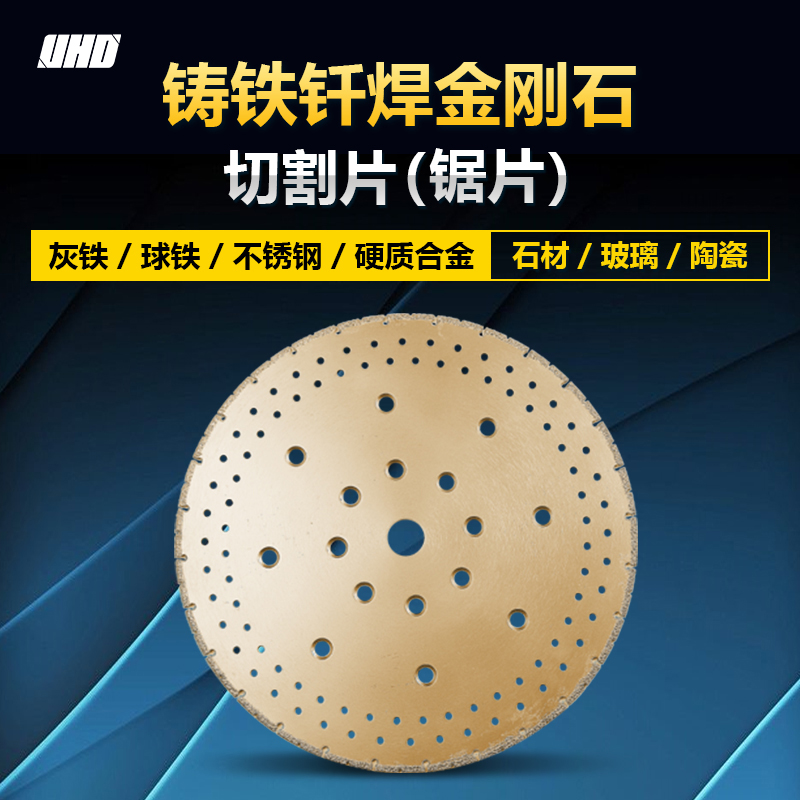

Brazing technology represents a significant innovation in the manufacturing of diamond saw blades. Compared with traditional welding technology, brazed diamond saw blades have better wear - resistance and cutting efficiency.

Traditional welding technology often has problems such as uneven distribution of diamond particles and poor bonding strength between the diamond and the base material. In contrast, brazing technology can firmly bond diamond particles to the base material, ensuring that the diamond particles can maintain a stable cutting performance during the cutting process. Tests have shown that the wear - resistance of a brazed diamond saw blade is 2 - 3 times that of a traditionally welded saw blade, and the cutting efficiency can be increased by 15 - 20%.

Proper maintenance of the saw blade is essential to ensure its long - term performance. One of the key aspects is to identify the wear of the blade head. When the height of the blade head is reduced by more than 30% of its original height, it is time to replace the saw blade. This can prevent safety accidents caused by excessive wear of the saw blade.

Regarding the choice of cooling methods, as mentioned above, wet cutting is a better option. However, if dry cutting is necessary, it is recommended to use a saw blade with a heat - resistant design and to pause the cutting operation regularly to allow the saw blade to cool down.

To further illustrate the performance of the 400mm brazed diamond saw blade, let's look at some data and case studies. In a series of cutting tests on different concrete materials, the 400mm brazed diamond saw blade showed an average cutting speed of 20 - 30 cm/min in medium - strength concrete (compressive strength of 30 - 60 MPa), while the cutting speed of a traditional saw blade was only 15 - 20 cm/min.

In a large - scale floor treatment project, a construction company switched from using traditional saw blades to 400mm brazed diamond saw blades. As a result, they completed the project 10 days ahead of schedule, saving approximately 15% of the overall project cost due to increased efficiency and reduced saw blade replacement frequency.

Based on the above analysis, the 400mm brazed diamond saw blade is an excellent choice for concrete cutting in construction projects. Its superior performance in terms of wear - resistance, cutting efficiency, and applicability in various construction scenarios makes it a reliable tool for construction professionals.

If you are looking for a high - quality saw blade for your construction project, we highly recommend our 400mm brazed diamond saw blade. It is designed with the latest brazing technology and high - quality diamond particles to meet the most demanding construction requirements. Click here to learn more about our product.

| Question | Answer |

|---|---|

| Can the 400mm brazed diamond saw blade be used for dry cutting? | Yes, it can be used for dry cutting, but wet cutting is recommended to extend the service life of the saw blade. |

| How to identify the wear of the blade head? | When the height of the blade head is reduced by more than 30% of its original height, it is time to replace the saw blade. |

We encourage you to leave your comments and questions below. Your feedback is valuable to us and can help us improve our products and services.