In the field of stone processing and construction, the noise and vibration generated during the cutting process have a significant impact on the operator's experience and the service life of the equipment. According to industry surveys, excessive vibration can reduce the service life of cutting equipment by up to 30% and seriously affect the cutting accuracy and efficiency. Therefore, controlling mechanical vibration and extending the service life of saw blades have become crucial issues in the industry.

The design of the cutter head arrangement, including cutter head density, angle, and spacing, has a direct impact on the vibration of the saw blade. For example, a higher cutter head density can generally improve the cutting efficiency, but it may also increase the vibration amplitude. Through a large number of experiments, it has been found that when the cutter head density is between 30% - 40%, the angle is 15° - 20°, and the spacing is 8 - 10 mm, the saw blade can maintain a relatively stable cutting state with lower vibration.

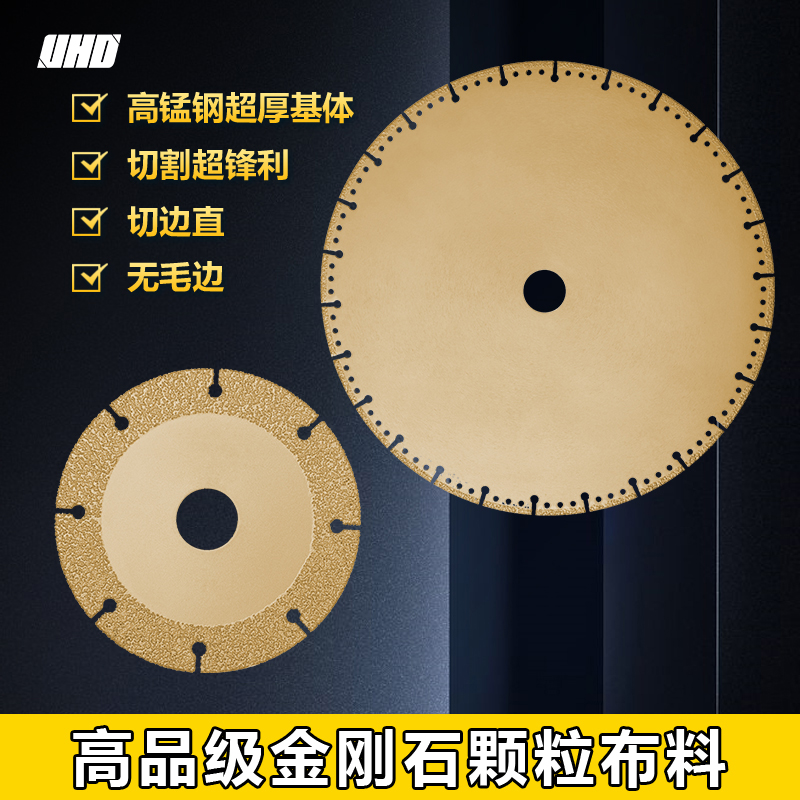

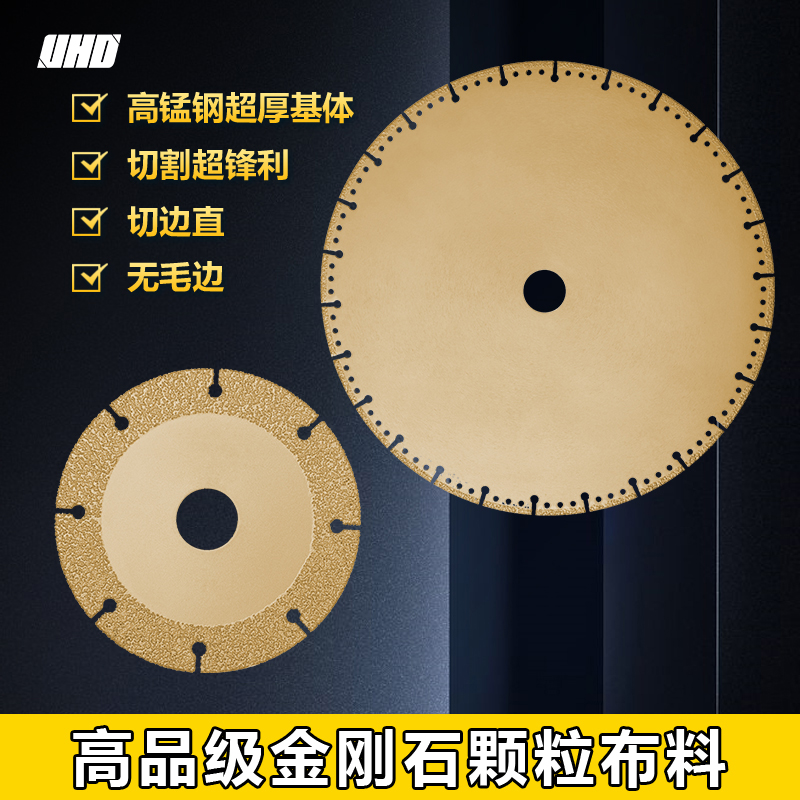

When selecting the substrate material for a saw blade, it is necessary to balance the rigidity and vibration absorption performance. Rigid materials can ensure the stability of the saw blade during high - speed cutting, while materials with good vibration absorption performance can effectively reduce vibration. For example, alloy steel with a certain carbon content can provide both sufficient rigidity and a certain degree of vibration absorption. By adjusting the carbon content and heat treatment process, the comprehensive performance of the saw blade can be optimized.

The brazing process is also a key factor affecting the performance of the saw blade. Controlling the brazing temperature, time, and filler metal selection can effectively coordinate the release of thermal stress and the bonding strength. For example, when the brazing temperature is controlled at 800 - 900°C and the time is 3 - 5 minutes, the saw blade can achieve a good balance between thermal stress release and bonding strength, thereby improving the overall performance and service life of the saw blade.

Combined with actual cases in stone processing and construction, different saw blade performance under various rotational speeds and feed rates has been observed. For instance, in a large - scale building construction project, when the rotational speed of the saw blade was 3000 - 3500 r/min and the feed rate was 5 - 8 mm/min, the saw blade showed high cutting efficiency and low vibration. However, when the rotational speed was too high or the feed rate was too fast, the vibration increased significantly, and the service life of the saw blade was shortened. Therefore, adjusting the rotational speed and feed rate according to the actual situation can improve the cutting performance of the saw blade.

Front - line technicians have accumulated a wealth of practical experience in identifying abnormal vibration and adjusting fixture stability. For example, they can quickly identify the source of abnormal vibration through listening to the sound and observing the cutting state of the saw blade. In addition, adjusting the fixture to ensure the stability of the saw blade during operation can effectively reduce vibration and improve cutting accuracy.

In conclusion, the selection of substrate materials, cutter head arrangement design, brazing process control, and operational adjustment strategies all have a significant impact on controlling the mechanical vibration of the saw blade and extending its service life. By combining theory with practice, the efficiency and safety of cutting operations can be effectively improved.