In the fiercely competitive industrial manufacturing sector, acquiring cutting tools that deliver peak efficiency, durability, and operational safety can decisively impact production costs and quality outcomes. The ZS400H brazed diamond saw blade represents a breakthrough in cutting technology by integrating advanced diamond particle composition with a robust high-manganese steel ultra-thick substrate. This unique design not only enhances wear resistance but also improves overall cutting productivity and workplace safety.

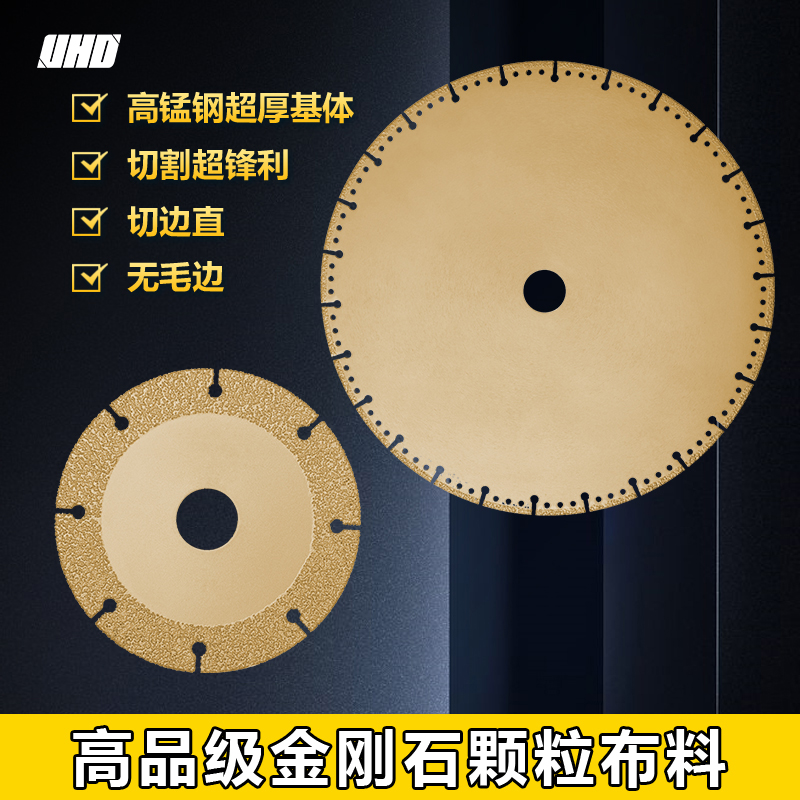

The ZS400H employs a meticulously engineered distribution of premium-grade diamond particles that ensure superior hardness and cutting sharpness. Combined with a high-manganese steel base plate designed to optimize impact absorption and resistance to deformation, the blade ensures consistent cutting performance in the most demanding industrial environments.

Compared with conventional blades, ZS400H boasts:

To fully leverage the technological benefits of ZS400H, industrial users can adopt the following operational best practices:

| Tip | Implementation | Expected Benefit |

|---|---|---|

| 1. Consistent Blade Speed Control | Maintain a steady blade rotation speed tailored to material hardness. | Maximized cut quality with reduced thermal damage. |

| 2. Optimize Feed Pressure | Apply balanced feed pressure to avoid blade overloading. | Extended blade lifespan and stable cutting efficiency. |

| 3. Employ Proper Cooling Techniques | Use appropriate water or air cooling to dissipate heat effectively. | Prevention of premature blade wear and material warping. |

| 4. Regular Inspection and Cleaning | Conduct routine checks for blade integrity and clean cutting surfaces. | Maintained peak cutting performance and minimized downtime. |

| 5. Training for Operational Best Practices | Equip operators with knowledge on handling and troubleshooting ZS400H blades. | Reduced human error and enhanced workplace safety. |

A leading structural steel fabricator in Europe reported an average 40% improvement in cutting cycle efficiency after integrating ZS400H blades into their production lines. Their data showed a reduction in blade replacement frequency by 45%, directly translating into lower operational expenses and material waste. Additionally, the quieter cutting operation and reduced dust generation positively impacted workplace health and safety compliance.

The high wear resistance of the ZS400H blade limits replacement frequency, leading to reduced scrap and energy consumption in blade manufacturing cycles. Its stable cutting profile also minimizes hazardous vibrations and airborne particulates, aligning with evolving global industrial environmental standards and workplace safety regulations.

Selecting the ZS400H brazed diamond saw blade empowers industrial operators with a cutting-edge tool that balances durability, efficiency, and safety. By implementing consistent operational strategies — such as speed control, feed pressure optimization, and systematic maintenance — enterprises can unlock substantial gains in productivity and cost-effectiveness. The ZS400H is not only a product of advanced engineering but also a strategic asset in enhancing industrial competitiveness in today’s cost-sensitive global marketplace.